Battery electrode coating film composition or separator coating film composition, battery electrode or separator having a coating film obtained using the coating film composition, and battery having the battery electrode or separator

A battery electrode and composition technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, battery pack components, etc., can solve the problems of insufficient charging and discharging capacity, penetration of conductive foreign matter, deterioration of active material layers, etc. Achieve excellent charge and discharge cycle characteristics, large charge and discharge capacity, and curb suppression effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

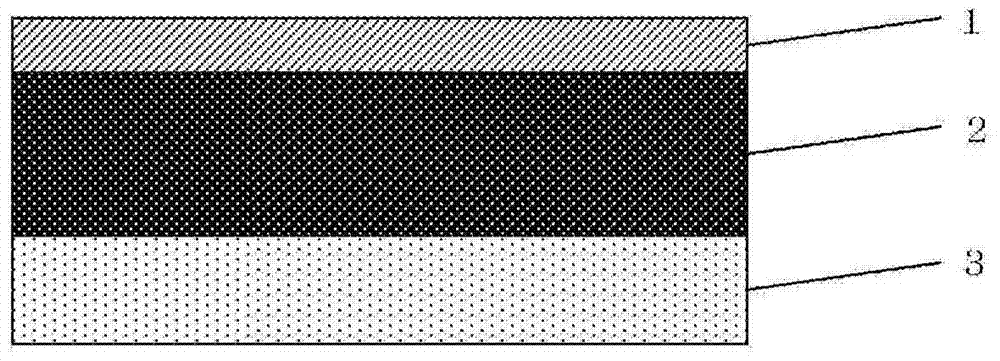

[0236] In Example 1, the battery electrode coating film composition or separator coating film composition composed of solvent, binder and viscoelastic particles is coated on the negative electrode, and the solvent is evaporated, thereby obtaining a negative electrode with a coating film. A method of producing a lithium ion secondary battery using this negative electrode will be described.

[0237] (manufacture of composition)

[0238] (Preparation of viscoelastic particle slurry 1)

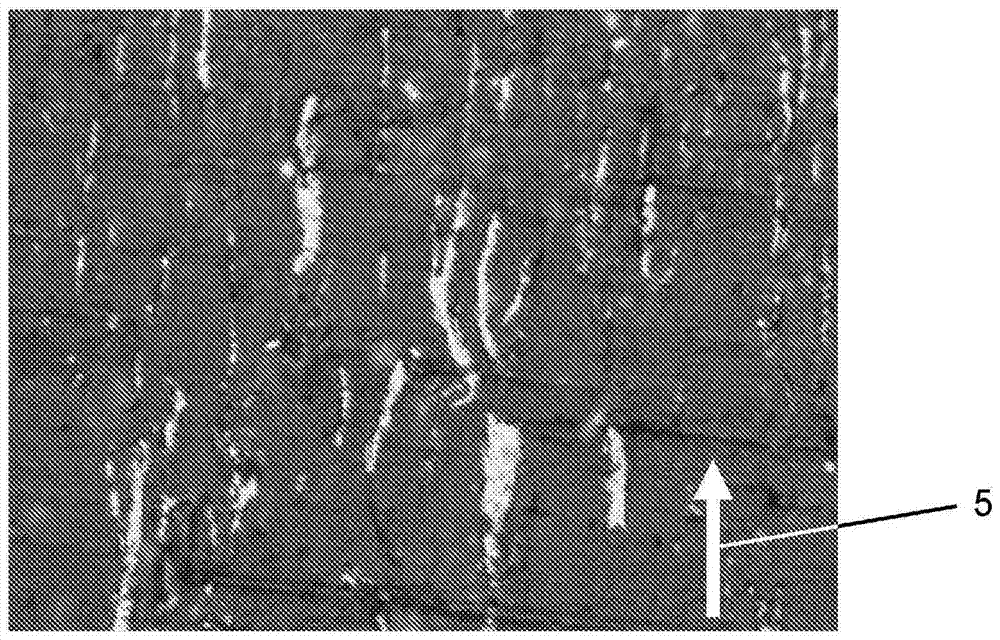

[0239] Add 10 L of ion-exchanged water and 50 kg of urethane particles (manufactured by Negami Industry Co., Ltd.: 60% water mixture of 2 μm particles of low elastic modulus urethane: Art Pearl MM-120TW) to a 100 L polypropylene tank, and stir 12 hours to make a 50% dispersion. The dispersion was filtered through a nylon mesh with a mesh size of 20 μm, and magnetic foreign matter was removed using a 2T electromagnet, and water removed during the process was added to prepare a dispersion containi...

Embodiment 2

[0251] In Example 2, the battery electrode coating film composition or separator coating film composition composed of solvent, binder and viscoelastic particles is coated on the positive electrode, and the solvent is evaporated, thereby obtaining a positive electrode with a coating film. A method of producing a lithium ion secondary battery using this positive electrode will be described.

[0252] (manufacture of composition)

[0253] It was produced by the same method as in Example 1.

[0254] (production of positive electrode)

[0255] Manufactured by the method of Example 1.

[0256] (manufacture of negative electrode)

[0257] Manufactured by the method of Example 1.

[0258] (Manufacture of positive electrode with coating film)

[0259] The positive electrode was manufactured by the method of Example 1.

[0260] (manufacture of lithium-ion secondary batteries)

[0261] Manufactured by the method of Example 1.

Embodiment 3

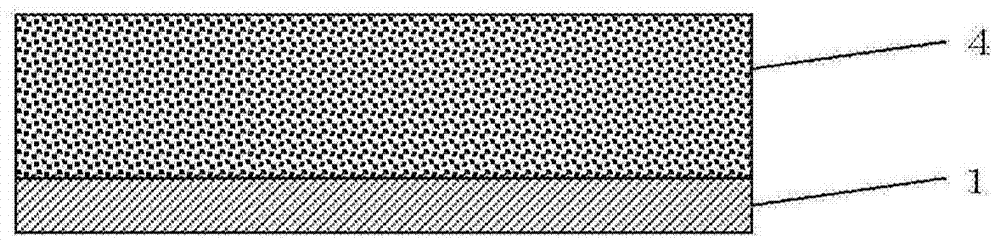

[0263] In Example 3, the battery electrode coating film composition or separator coating film composition composed of solvent, binder and viscoelastic particles is coated on the separator, and the solvent is evaporated, thereby obtaining a separator with a coating film , a method of manufacturing a lithium ion secondary battery using the separator will be described.

[0264] (manufacture of composition)

[0265] It was produced by the same method as in Example 1.

[0266] (production of positive electrode)

[0267] Manufactured by the method of Example 1.

[0268] (manufacture of negative electrode)

[0269] Manufactured by the method of Example 1.

[0270] (Manufacture of separator with coating film)

[0271] A separator was produced by the same method as in Example 1.

[0272] (manufacture of lithium-ion secondary batteries)

[0273] Manufactured by the method of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com