Preparation method and application of heavy-metal removing agent for temporary shellfish cultivation

A heavy metal and remover technology, which is applied in application, fish farming, climate change adaptation, etc., can solve the problems of poor heavy metal removal effect and inapplicable heavy metal removal, and achieve simple use method, ensure food safety, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

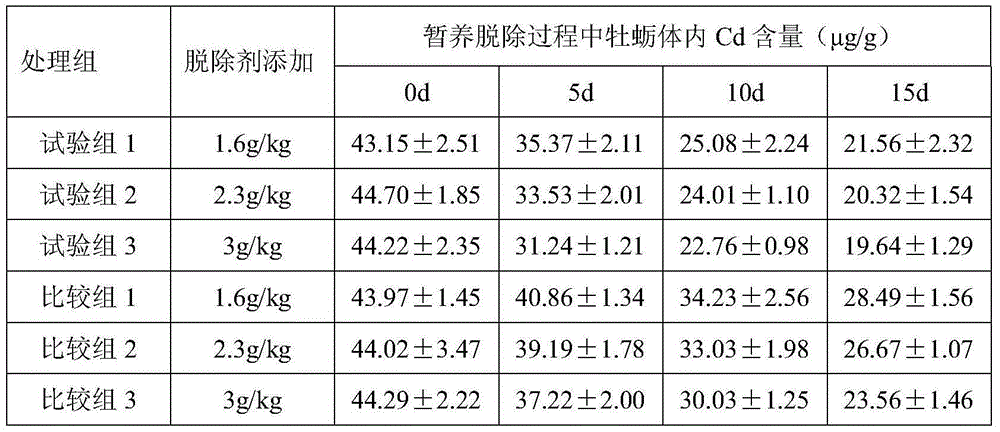

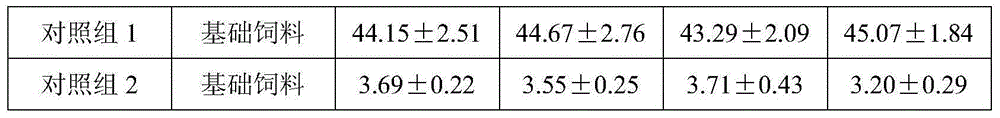

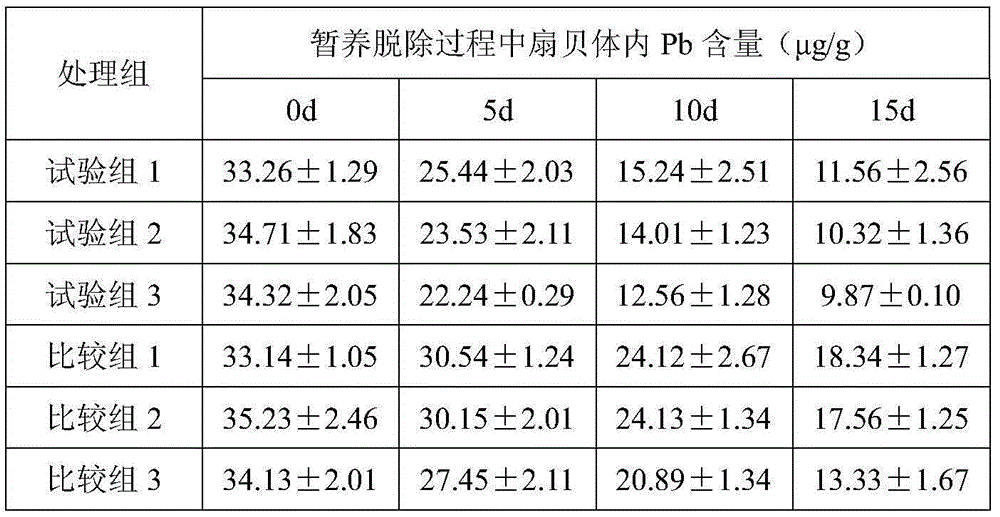

Examples

Embodiment 1

[0019] Embodiment 1: preparation of heavy metal removal agent for temporary cultivation of shellfish

[0020] Get carrageenan oligosaccharide (polymerization degree is 3) and put into phosphate buffer, the volume ratio of phosphate buffer addition and carrageenan oligosaccharide is 40:1, the concentration of phosphate buffer is 0.25mol / L, pH value is 5.5. After the carrageenan oligosaccharide is fully dissolved, then add sodium selenite, the mass ratio of carrageenan oligosaccharide to sodium selenite is 5:1, adjust the pH value of the solution to neutral, and shake and react at room temperature for 2 hours. After the reaction, 3 times the volume of ethanol was added to the reaction solution, alcohol precipitation overnight, vacuum filtration and freeze-drying to obtain the phosphorylated carrageenan oligosaccharide-selenium complex.

[0021] Mix the phosphorylated carrageenan oligosaccharide-selenium complex prepared above, EDTA-sodium iron, EDTA-sodium zinc, β-glucan and Vc...

Embodiment 2

[0022] Embodiment 2: preparation of heavy metal removal agent for temporary cultivation of shellfish

[0023] Get carrageenan oligosaccharide (polymerization degree is 6) and put into phosphate buffer, the volume ratio of carrageenan oligosaccharide adding amount of carrageenan oligosaccharide buffer is 50:1, the concentration of phosphate buffer is 0.1mol / L, pH value is 6.5. After the carrageenan oligosaccharides were fully dissolved, sodium selenite was added, the mass ratio of carrageenan oligosaccharides to sodium selenite was 6:1, the pH value of the solution was adjusted to neutral, and the reaction was shaken at room temperature for 3 hours. After the reaction, 5 times the volume of ethanol was added to the reaction solution, alcohol precipitation overnight, vacuum filtration and freeze-drying to obtain the phosphorylated carrageenan oligosaccharide-selenium complex.

[0024] Mix the phosphorylated carrageenan oligosaccharide-selenium complex prepared above, EDTA-sodiu...

Embodiment 3

[0025] Embodiment 3: preparation of heavy metal removal agent for temporary cultivation of shellfish

[0026] Get carrageenan oligosaccharide (polymerization degree is 9) and put into phosphate buffer, the volume ratio of phosphate buffer addition and carrageenan oligosaccharide is 60:1, the concentration of phosphate buffer is 0.18mol / L, pH value for 6. After the carrageenan oligosaccharide is fully dissolved, then add sodium selenite, the mass ratio of carrageenan oligosaccharide to sodium selenite is 7:1, adjust the pH value of the solution to neutral, and shake and react at room temperature for 4 hours. After the reaction, 5 times the volume of ethanol was added to the reaction solution, alcohol precipitation overnight, vacuum filtration and freeze-drying to obtain the phosphorylated carrageenan oligosaccharide-selenium complex.

[0027] Mix the phosphorylated carrageenan oligosaccharide-selenium complex prepared above, EDTA-sodium iron, EDTA-sodium zinc, β-glucan and Vc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com