Preparation method for high-purity gleditsia sinensis natural surfactant

A surfactant and high-purity technology, applied in the direction of non-ionic surface active compounds, skin care preparations, chemical instruments and methods, etc., can solve the problems of low extraction rate and purity of natural surfactants from acacia, and achieve high extraction rate , Improve the extraction rate and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Dried the acacia peel and crushed to 30 mesh, then submerged in distilled water with 40 times the mass, extracted with ultrasonic wave at a power of 4000w for 50min, and then added biological enzymes (neutral protease, fiber Sulfase and pectinase in an equal volume ratio), then carry out enzymatic hydrolysis at 50°C and pH 7 for 4 hours, and then obtain the filtrate and filter residue by filtration;

[0020] (2) Repeat the operation of step (1) for 5 times with the obtained filter residue, and combine the filtrate to obtain the saponins extract;

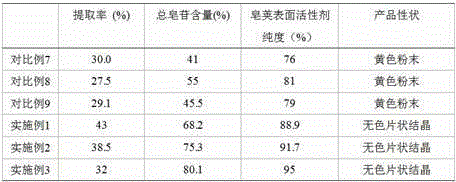

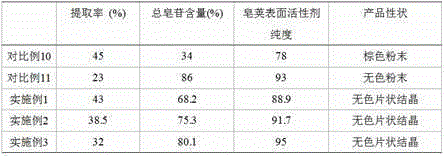

[0021] (3) The saponins extract obtained in step (2) was concentrated under reduced pressure at 50°C to a thick paste, and then dried to obtain the total saponins extract of saponins; the extraction rate was 43%, and the total saponins content was 68.2%;

[0022] (4) Add 30 mass times of sulfuric acid solution with a mass concentration of 1.0% to the total saponin extract obtained in step (3), then heat and reflux for 6 ho...

Embodiment 2

[0024] (1) Dry the acacia peel and crush it to 20 meshes, then immerse in 50 times the mass of ethanol with a volume concentration of 50%, extract with ultrasonic wave at a power of 6000w for 20min, and then add biological enzymes at 0.5% of the total volume (a mixture of neutral protease, cellulase and pectinase in an equal volume ratio), and then carry out enzymatic hydrolysis at 40°C and pH 8 for 2 hours, and then obtain the filtrate and filter residue by filtration;

[0025] (2) Repeat the operation of step (1) for the obtained filter residue 4 times, and combine the filtrate to obtain the saponins extract;

[0026] (3) The saponins extract obtained in step (2) was concentrated under reduced pressure at 50°C to a thick paste, and then dried to obtain the total saponins extract of saponins; the extraction rate was 38.5%, and the total saponins content was 75.3%;

[0027] (4) Add 20 mass times of sulfuric acid solution with a mass concentration of 0.5% to the total saponin e...

Embodiment 3

[0029] (1) Dry the acacia peel and crush it to 40 meshes, then immerse in 30 times the mass of ethanol with a volume concentration of 70%, extract with ultrasonic wave at a power of 2000w for 60min, and then add biological enzymes at 0.5% of the total volume (a mixture of neutral protease, cellulase and pectinase in an equal volume ratio), and then carry out enzymatic hydrolysis at 30°C and pH 7 for 5 hours, and then obtain the filtrate and filter residue by filtration;

[0030] (2) Repeat the operation of step (1) for the obtained filter residue 3 times, and combine the filtrate to obtain the saponins extract;

[0031] (3) The saponins extract obtained in step (2) was concentrated under reduced pressure at 50°C to a thick paste, and then dried to obtain the total saponins extract of saponins; the extraction rate was 32%, and the total saponins content was 80.1%;

[0032] (4) Add 25 mass times of sulfuric acid solution with a mass concentration of 0.8% to the total saponin ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com