A powder metallurgy method and product for preparing a bearing sleeve of an automobile seat lifter

A car seat and powder metallurgy technology, which is applied in the field of powder metallurgy production, can solve the problems of complex cold pier mold structure, large machining volume, high mold strength requirements, etc., to meet the requirements of stable mass production, uniform and sufficient material alloying, Good product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

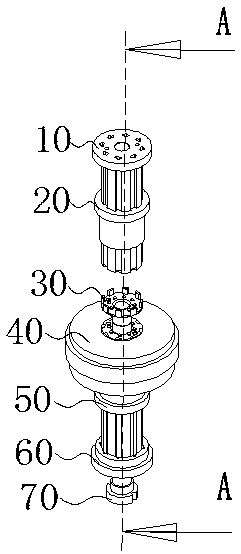

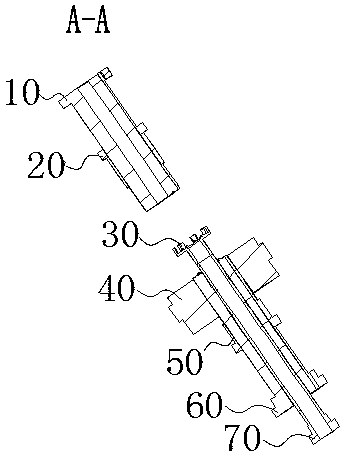

Image

Examples

Embodiment 1

[0018] A powder metallurgy method for preparing a bearing sleeve of an automobile seat lifter, which is specifically carried out according to the following steps:

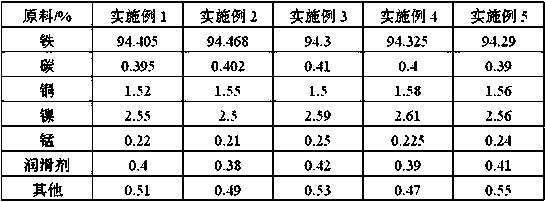

[0019] (1) Powder mixing: put a certain proportion of graphite powder, nickel, copper, manganese-containing diffusion alloyed steel powder and special lubricant into the double-cone mixer and mix for 50 minutes, and mix evenly. The proportion by weight is: iron 94-96%, carbon 0.3-0.5%, copper 1.5-2%, nickel 2.5-3%, manganese 0.2-0.3%, lubricant 0.3-0.6%, other less than 1%, its weight The specific weight is 100%, and the appropriate proportion of carbon, nickel and copper ensures the dimensional accuracy of the compact, reduces the finished size, and has good product consistency. The appropriate nickel also makes the hardenability of the product good, which is improving The strength of the product does not reduce the plasticity and toughness, and the effect is better by adding a small amount of manganese at the sam...

Embodiment 2

[0032] Example 2 The same method as in Example 1 was carried out. The process parameters of the preparation method are listed in Table 1. The performance of the bearing sleeve of the car seat lifter obtained in this example is tested, and the performance parameters are listed in Table 2.

Embodiment 3

[0033] Example 3 The same method as in Example 1 was carried out. The process parameters of the preparation method are listed in Table 1. The performance of the bearing sleeve of the car seat lifter obtained in this example is tested, and the performance parameters are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com