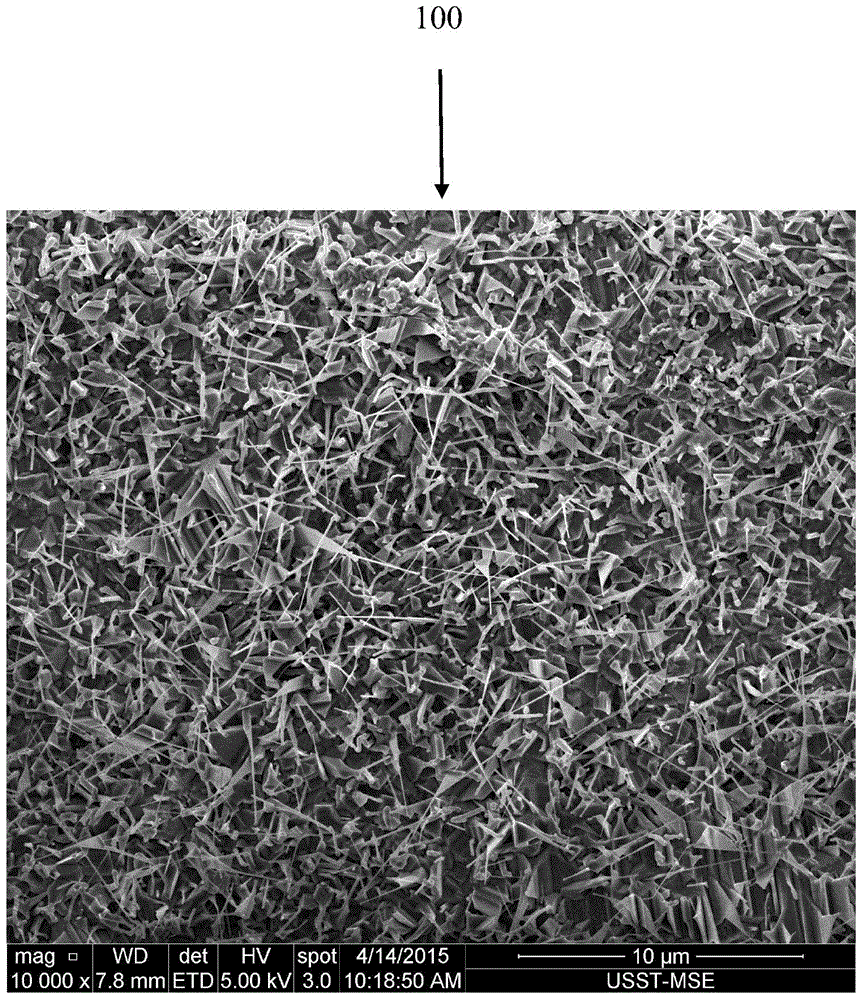

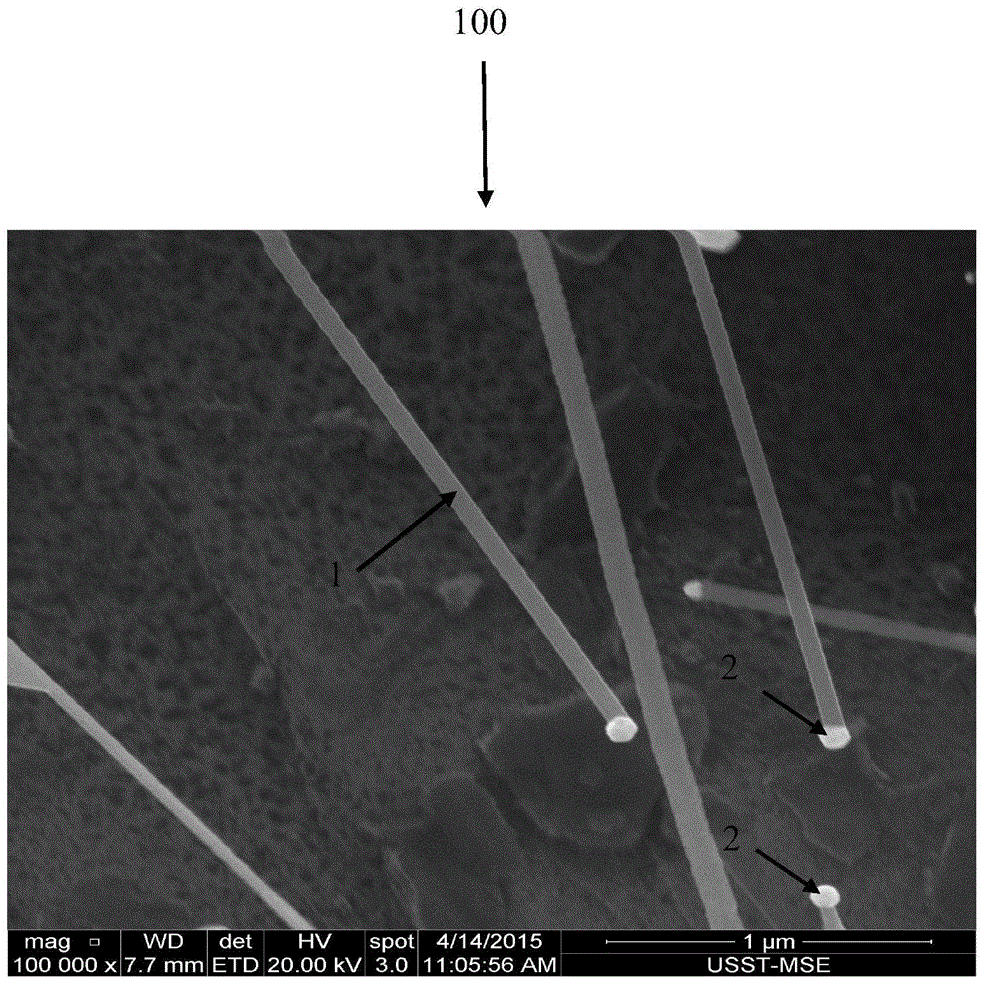

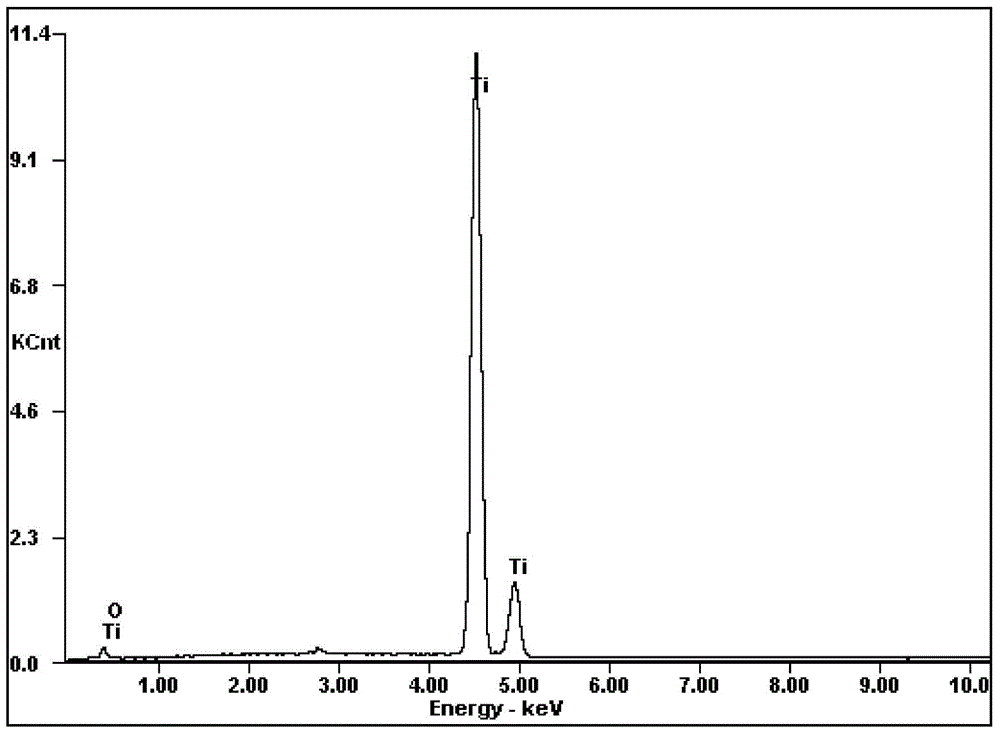

Titanium dioxide nanowire and preparation method thereof

A technology of titanium dioxide and nanowires, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of poor bonding force of nanowire film, thick nanowire diameter, complex preparation process, etc., and achieve improved dispersion properties, high specific surface area, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method for growing titanium dioxide nanowires in situ, comprising the following steps:

[0045] i) Pipette 50ml 5% TiO 2 Nano Collagen Solution, TiO in Nano Collagen Solution 2 The particle size is 10nm, add polyethylene glycol-4000.1g, dilute to 100ml with distilled water, and ultrasonically disperse for 20 minutes to obtain TiO with a solid content of 2.5%. 2 Nano sol mother liquor, wherein the nano sol mother liquor contains organic matter with a mass fraction of 0.1%;

[0046] ii) The TiO obtained in step i is prepared by wet impregnation 2 The nano-sol mother liquor is coated on the surface of the nanoporous gold film, and the TiO in the nanoporous gold film 2 The load is 4.7%;

[0047] iii) taking out the nanoporous gold film coated with the nano-sol mother liquor from the nano-sol mother liquor with a Ti plate, and air-drying the Ti plate naturally to obtain a nanoparticle-Ti plate loaded with nanoparticles;

[0048] iv) placing the nanoparticl...

Embodiment 2

[0062] A preparation method for growing titanium dioxide nanowires in situ, comprising the following steps:

[0063] i) pipette 50ml0.5%TiO 2 Nano Collagen Solution, TiO in Nano Collagen Solution 2 The particle size is 5nm, add 2g of urea, dilute to 100ml with distilled water, and ultrasonically disperse for 20 minutes to obtain TiO with a solid content of 2.5%. 2 Nano sol mother liquor, wherein the nano sol mother liquor contains organic matter with a mass fraction of 2%;

[0064] ii) The TiO obtained in step i is prepared by wet impregnation 2 The nano-sol mother liquor is coated on the surface of the nanoporous gold film, and the TiO in the nanoporous gold film 2 The loading is 0.4%;

[0065] iii) taking out the nanoporous gold film coated with the nano-sol mother liquor from the nano-sol mother liquor with a Ti plate, and air-drying the Ti plate naturally to obtain a nanoparticle-Ti plate loaded with nanoparticles;

[0066] iv) placing the nanoparticle-Ti plate in ste...

Embodiment 3

[0069] A preparation method for growing titanium dioxide nanowires in situ, comprising the following steps:

[0070] i) Pipette 20ml of 1% TiO 2 Nano Collagen Solution, TiO in Nano Collagen Solution 2 The particle size is 2nm, add 4.5g of citric acid, dilute to 100ml with distilled water, and ultrasonically disperse for 20 minutes to obtain TiO with a solid content of 0.2%. 2 Nano sol mother liquor, wherein the nano sol mother liquor contains 4.5% organic matter by mass fraction;

[0071] ii) The TiO obtained in step i was coated by spin coating method 2 The nano-sol mother liquor is coated on the surface of the nanoporous gold film, and the TiO in the nanoporous gold film 2 The load is 2%;

[0072] iii) taking out the nanoporous gold film coated with the nano-sol mother liquor from the nano-sol mother liquor with a Ti plate, and air-drying the Ti plate naturally to obtain a nanoparticle-Ti plate loaded with nanoparticles;

[0073] iv) placing the nanoparticle-Ti plate in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com