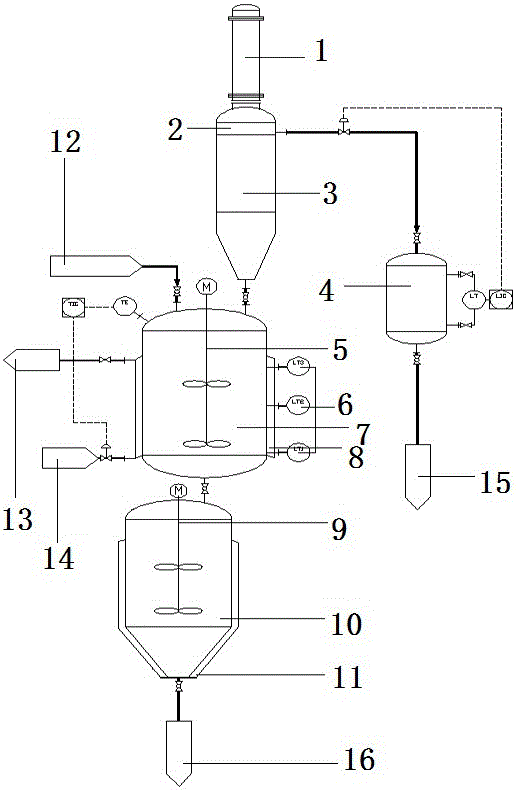

Method and device for recovering efficient high-boiling substance from organic silicon residue slurry

An organic silicon slurry technology with high efficiency, applied in the direction of silicon organic compounds, organic chemistry, chemical instruments and methods, etc., can solve the problems of high solid content in slurry, high requirements for conveying devices and stirring devices, and ineffective utilization , to achieve the effect of high cracking rate, low requirements for stirring and conveying devices, and avoiding fires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Turn on the heating device and stirring device of the distillation kettle, the stirring speed is about 60 rpm, turn on the circulating water device of the top condenser, and synthesize the methyl chlorosilane monomer into the slurry from the washing tower reboiler (temperature 200 °C, containing The solid content is about 25%), and it is directly discharged into the still at a rate of 0.8t / h to control the liquid level of the still.

[0028] The temperature is maintained at 170°C, and when liquid appears in the distributor at the top of the packed column, the extraction of high boilers is controlled. When the recovery rate of high boiling substances is 0.3t / h, the cracking rate of the obtained high boiling substances reaches 86%. After the liquid level of the distillation kettle reaches a high level and alarms, the distillation is stopped, and the high temperature residue is discharged into the cooling kettle and cooled to 60°C After the discharge system, the solid cont...

Embodiment 2

[0030] Other implementation conditions are the same as 1. When the recovery rate of the high-boiler receiving tank is 0.4t / h, the cracking rate of the produced high-boiler is only 70%, and the solid content of the discharged residue increases by about 25%. The residue discharge is not smooth and the resistance is relatively large.

Embodiment 3

[0032] Other implementation conditions are the same as 1. When the recovery rate of the high-boiler receiving tank reaches 0.25t / h, the cracking rate of the produced high-boiler is as high as 90%, and the solid content of the discharged residue increases by about 11.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com