Polymer nano / micro particle additive and preparation method thereof

A technology of micron particles and polymers, applied in the field of admixtures for cement-based materials, can solve the problems of reducing the later strength of mortar or concrete, limiting the wide application of early strength agents, etc., to achieve the effect of improving toughness and improving early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

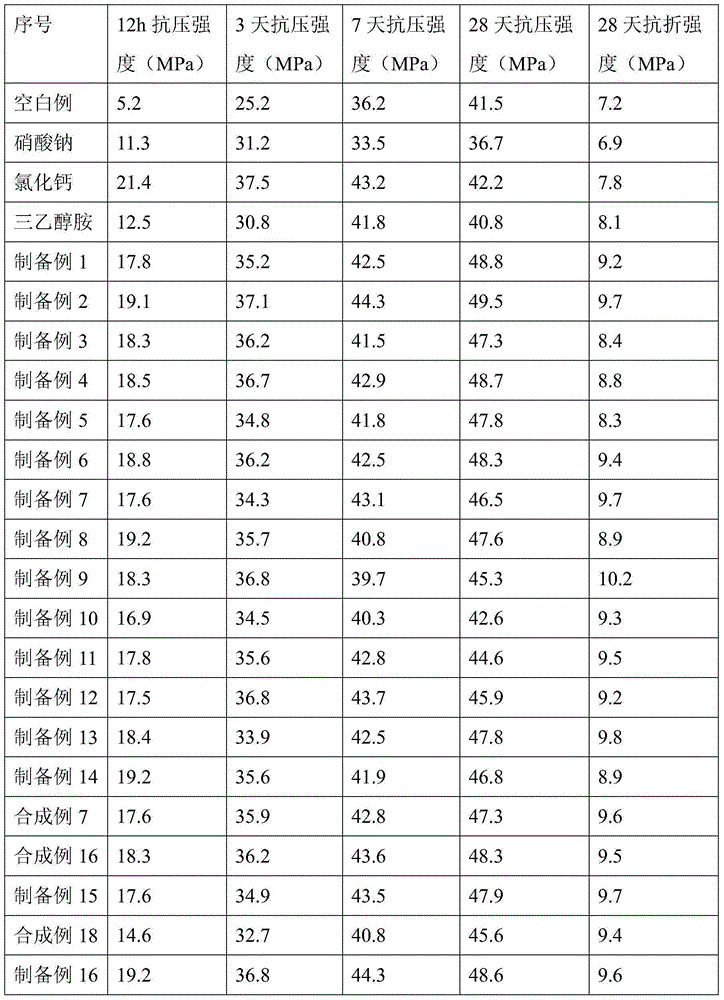

Examples

Synthetic example 1

[0050] Add 2kg of γ-methacryloxypropyltriethoxysilane to one elevated tank, add 8kg of vinylpyrrolidone to another elevated tank, and add 0.7kg of ammonium persulfate to the third elevated tank at the same time. 20kg of ionized water is added dropwise as an initiator.

[0051] Put 80kg of deionized water and 70kg of TPEG (prenyl polyoxyethylene ether, molecular weight 2400) into the reaction kettle, raise the temperature to 80 degrees, and start adding the above three components dropwise. Among them, the first two components were added dropwise for three hours, and the initiator component was added dropwise for three and a half hours. After the drop, the temperature was kept for 30 minutes. At the same time, a solution A consisting of 0.1 kg of tert-butyl hydroperoxide and 5 kg of water was added dropwise, 0.05 Solution B composed of 1 kg of sodium thiosulfate and 5 kg of deionized water was added dropwise for 2 hours, then kept warm for half an hour, cooled to below 50 degree...

Synthetic example 2

[0053] Add 5kg of deionized water and 8kg of vinylpyrrolidone (NVP) in one elevated tank, add 1.1kg of sodium persulfate and 10kg of deionized water in another elevated tank, and add components dropwise as an initiator.

[0054] Put 50kg of deionized water and 50kg of TPEG (prenyl polyoxyethylene ether, molecular weight 1000) with phosphoric acid functional groups in the reaction kettle, raise the temperature to 90 degrees, and start adding the above two components dropwise. Among them, the former component was added dropwise for three hours, and the initiator component was added dropwise for three and a half hours. After the drop, the temperature was kept for 30 minutes, and the temperature was lowered to 85 degrees. At the same time, 0.42 kg of tert-butyl hydroperoxide and 5 kg of water were added dropwise to form Solution A, 0.25 kilograms of sodium thiosulfate and 5 kilograms of deionized water form solution B, dropwise for 2 hours, then keep warm for half an hour, cool to ...

Synthetic example 3

[0056] Add 90kg of deionized water, 5kg of acrylamide, and 17kg of HPEG (isobutenyl polyoxyethylene ether, molecular weight 4000) with phosphoric acid functional groups in a high-level tank, add 68kg of styrene in another high-level tank, and at the same time in the third Add 1.1kg of sodium persulfate and 110kg of deionized water in a high position tank, and add components dropwise as an initiator.

[0057] 70kg of deionized water was dropped into the reactor, the temperature was raised to 90 degrees, and the above three components were started to be added dropwise. Among them, the first two components were added dropwise for three hours, and the initiator component was added dropwise for three and a half hours. After the drop, the temperature was kept for 30 minutes, and the temperature was dropped to 85 degrees. At the same time, 0.42 kg of tert-butyl hydroperoxide and 20 kg of water were added dropwise. The solution A that forms, the solution B that 0.25 kilograms of sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com