Preparation method of novel silicane fire retardant

A flame retardant and silane technology, which is applied in the field of preparation of new silane flame retardants, can solve the problems of high preparation cost, endanger the health of operators, product residues, etc. The effect of unaffected performance and moderate reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

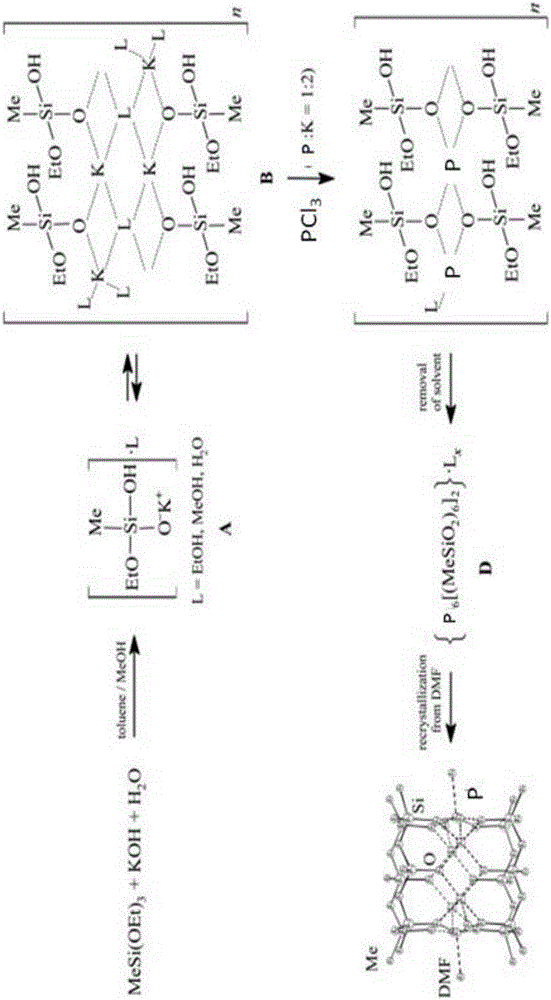

[0015] The preparation method of silane flame retardant of the present invention comprises the following steps:

[0016] 1) Using siloxane as a raw material, dissolve siloxane in an organic solvent, add potassium hydroxide catalyst, stir evenly, heat and reflux for 15-30 minutes to obtain a sodium complex;

[0017] 2) After cooling slightly, add phosphorus trichloride to replace, and then reflux for 25-40 minutes to convert the sodium complex into a phosphorus complex;

[0018] 3) After cooling, filter, concentrate the filtrate, and then cool to -5°C, white crystals are formed;

[0019] 4) Rinse the white crystals obtained in step 3) with methanol, and then dry them in a vacuum oven at room temperature for 0.6-1.5 hours to obtain the silane flame retardant.

[0020] Wherein, the weight fraction of each component is: 10-36 parts of siloxane, 0.06-6.8 parts of organic solvent, 5-16 parts of potassium hydroxide, and 0.02-1.7 parts of phosphorus trichloride. The siloxanes are vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com