Preparation method of tertiary amine-terminated polyether nonionic surfactant

A technology of terminal tertiary amino group polyether and non-ionic surface, which is applied in the field of preparation of tertiary amino group terminal polyether type nonionic surfactant, can solve the problems of long reaction time and cumbersome process, and achieves short reaction time and reaction time. The effect of high activity and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

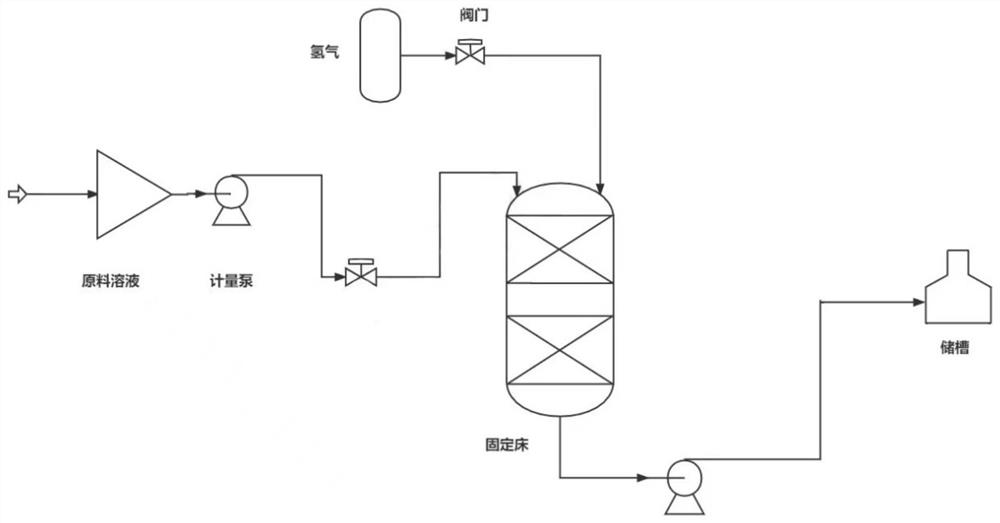

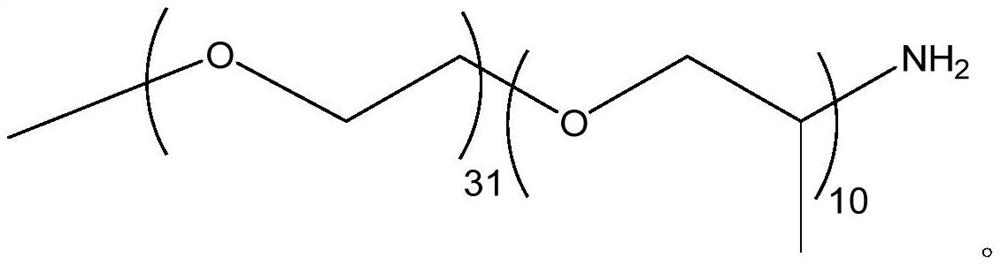

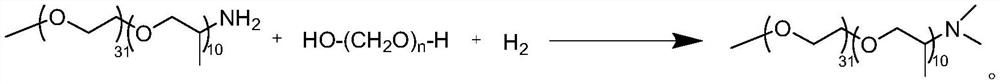

Method used

Image

Examples

Embodiment 1

[0035] Preparation of supported catalysts

[0036] (1) Place 60 g of commercially available carbon nanotubes in 300 mL of mixed acid solution (HNO 3 :H 2 SO 4 =3:1), ultrasonically treated for 2 hours at room temperature to obtain modified carbon nanotubes rich in a large number of oxygen-containing functional groups, diluted with 800 mL of deionized water, and then vacuum filtered. The solid obtained by suction filtration was washed with a large amount of deionized water until the pH of the deionized water after washing was neutral, and then the solid was vacuum-dried at 70 °C for 2 h to obtain the carrier f-MWCNTs.

[0037] (2) The carrier f-MWCNTs obtained in step (1) was placed in 500 mL of deionized water, and ultrasonically stirred at room temperature for 2 h, and then 145.4 g of Ni(NO 3 ) 2 , 55.8g of Cu (NO 3 ) 2 , 19.9g of H 8 N 2 O 4 The metal salt of W was dispersed in the above solution, and ultrasonic stirring was continued for 2h. After stirring, the mi...

Embodiment 2

[0040] The only difference from Example 1 is that the vacuum-dried solid matter in step (2) is calcined in a muffle furnace at 320° C. for 5 hours, and the remaining steps are the same as those in Example 1.

[0041] In the finally obtained supported catalyst Ni-Cu-W / f-MWCNTs, Ni, Cu, and W account for 4.5%, 2.5%, and 2.0% of the total weight of the supported catalyst, respectively.

Embodiment 3

[0043] The only difference from Example 1 is that the vacuum-dried solid matter in step (2) is calcined in a muffle furnace at 320° C. for 10 hours, and the remaining steps are the same as those in Example 1.

[0044] In the finally obtained supported catalyst Ni-Cu-W / f-MWCNTs, Ni, Cu, and W account for 4.7%, 3.0%, and 2.2% of the total weight of the supported catalyst, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com