Streptomyces albus decomposition accelerator and application thereof in saline-alkali soil straw decay soil condition improvement

A technology for improving soil by decomposing straws and Streptomyces albicans, which is applied in the fields of application, bacteria, and preparation of organic fertilizers, can solve the problems of unsatisfactory organic matter content and carbon-nitrogen ratio of straws, long decomposing period, soil salt content and soil bulk density, etc. To achieve the effect of increasing soil humus content, increasing soil porosity, and reducing soil salinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

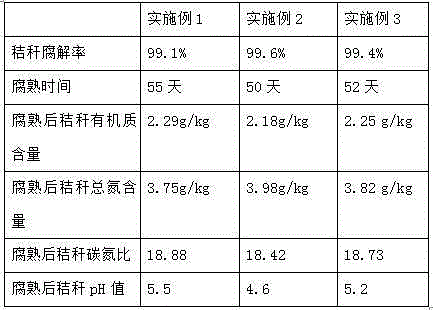

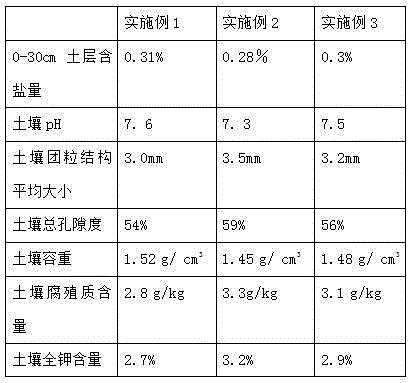

Examples

Embodiment 1

[0026] Embodiment 1 A kind of streptomyces albicans putrefaction agent

[0027] The raw material of described decomposing agent comprises the following components by weight ratio:

[0028] 2.2 parts of compound microbial bacteria powder, 36 parts of Ulmus bark, 24 parts of rose pollen, 6 parts of Scenedesmus curvae;

[0029] Described composite microbial bacterial powder comprises Streptomyces albicans 44 * 10 9 CFU / g, salt-tolerant Rhodopseudomonas capsulatum 30×10 9 CFU / g, Lactobacillus bulgaricus 5×10 9 CFU / g, Bacillus subtilis 14×10 9 CFU / g;

[0030] Described elm bark: the water content is 9%, the pectin content is 8.5%, and the oil content is 7.9%;

[0031] Said rose pollen: dried and ground rose powder, with a fineness of 200 mesh, a water content of 8%, a VE content of 0.35%, a VC content of 0.7%, and an aspartic acid content of 1.78% ;

[0032] Described Scenedesmus flexus: water content is 14%.

[0033] The above percentages are all percentages by mass.

...

Embodiment 2

[0047] Embodiment 2 A kind of streptomyces albicans putrefaction agent

[0048] The raw material of described decomposing agent comprises the following components by weight ratio:

[0049] 2.8 parts of compound microbial powder, 39 parts of Ulmus bark, 26 parts of rose pollen, 9 parts of Scenedesmus curvae;

[0050] Described composite microbial bacterial powder comprises Streptomyces albicans 44 * 10 9 CFU / g, salt-tolerant Rhodopseudomonas capsulatum 30×10 9 CFU / g, Lactobacillus bulgaricus 5×10 9 CFU / g, Bacillus subtilis 14×10 9 CFU / g;

[0051] Described elm bark: the water content is 9%, the pectin content is 8.5%, and the oil content is 7.9%;

[0052]Said rose pollen: dried and ground rose powder, with a fineness of 200 mesh, a water content of 8%, a VE content of 0.35%, a VC content of 0.7%, and an aspartic acid content of 1.78% ;

[0053] Described Scenedesmus flexus: water content is 14%.

[0054] The above percentages are all percentages by mass.

[0055] T...

Embodiment 3

[0056] Embodiment 3 A kind of streptomyces albicans putrefaction agent

[0057] The raw material of described decomposing agent comprises the following components by weight ratio:

[0058] 3.1 parts of compound microbial bacteria powder, 42 parts of Ulmus bark, 29 parts of rose pollen, 11 parts of Scenedesmus flexus;

[0059] Described composite microbial bacterial powder comprises Streptomyces albicans 44 * 10 9 CFU / g, salt-tolerant Rhodopseudomonas capsulatum 30×10 9 CFU / g, Lactobacillus bulgaricus 5×10 9 CFU / g, Bacillus subtilis 14×10 9 CFU / g;

[0060] Described elm bark: the water content is 9%, the pectin content is 8.5%, and the oil content is 7.9%;

[0061] Said rose pollen: dried and ground rose powder, with a fineness of 200 mesh, a water content of 8%, a VE content of 0.35%, a VC content of 0.7%, and an aspartic acid content of 1.78% ;

[0062] Described Scenedesmus flexus: water content is 14%.

[0063] The above percentages are all percentages by mass.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com