High-strength and low-expansion hot-rolled invar alloy

An Invar alloy and low-expansion technology, which is applied in the field of alloys, can solve the problems of complex strengthening process control, tensile strength less than 500, and difficulty in meeting performance requirements, so as to avoid insufficient strengthening effect, simplify process flow and production cost, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

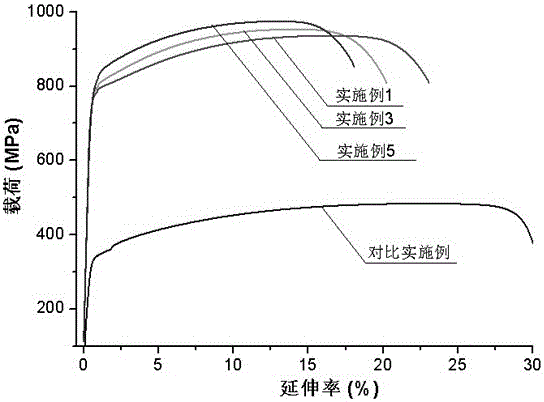

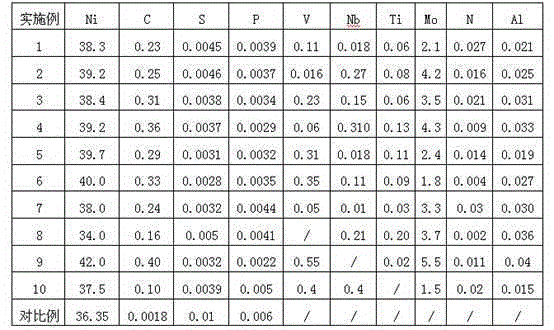

[0029] Embodiments 1-10: The high-strength and low-expansion hot-rolled Invar alloy is produced by using the following composition ratios.

[0030] The hot-rolled Invar alloy is smelted in a vacuum induction furnace, cast into an ingot, and rolled into a hot-rolled material required by the test size at one time; the composition ratio shown in Table 1 is used, and the 4J36 alloy is used as a comparison example. The samples of the examples and the comparative examples were all cast into ingots under an argon protection environment, the casting temperature was 1550°C, and then the ingots were solution treated at 1200°C for 1.5h, the initial rolling temperature was 1150°C, and the final rolling temperature It is 960°C. The difference is that the samples of Comparative Examples and Examples 1, 2, and 6 were directly water-cooled to room temperature after hot rolling; the samples of Examples 3, 4, and 7 were hot-rolled and directly water-cooled to 400 ° C, and then air-cooled to roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com