Electrodeposition decoppering and regenerating method of waste copper-bearing etching liquor of acidic chlorination system

A technology of etching waste liquid and copper etching, which is applied to the improvement of process efficiency, photography technology, instruments, etc., to achieve the effects of good flatness and compactness, stable equipment, economical feasibility, environmental friendliness, and economical improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

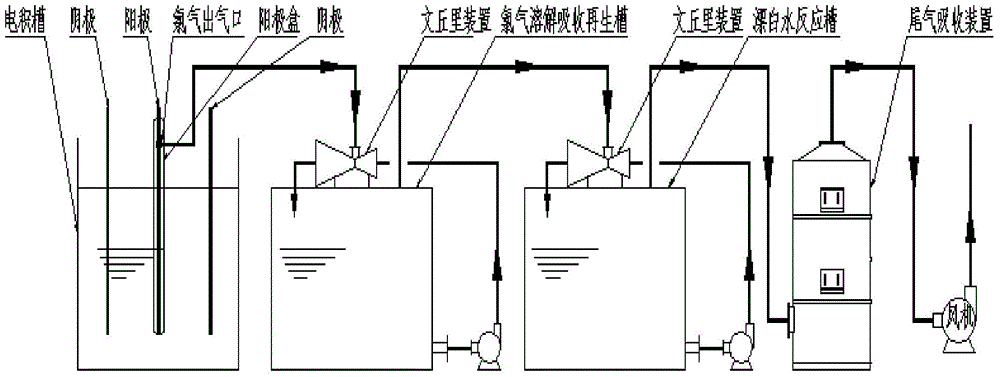

Image

Examples

Embodiment 1

[0028] A method for electrodeposition and regeneration of copper-containing etching waste liquid in an acidic chlorination system, comprising the following steps:

[0029] (1) Filter the copper-containing etching liquid waste liquid overflowing from the circuit board etching process, and pump the clarified copper-containing etching waste liquid without solid particles into the electrolyte circulation tank for subsequent use; the etching waste liquid copper The content is 80g / l, the concentration of hydrochloric acid is 1.5N;

[0030] (2) Pump the filtrate obtained in step (1) into the electrowinning tank for electrowinning and decoppering; the voltage of the electrowinning tank is 1.9V, and the current density is 500A / m 2 ; The temperature of the electrowinning waste liquid is 50°C;

[0031] (3) The cathode copper obtained in step (2) (when the weight of copper reaches 20kg) is dried with compressed air after scalding, and packed into the warehouse; the scalding condition is ...

Embodiment 2

[0037] A method for electrodeposition and regeneration of copper-containing etching waste liquid in an acidic chlorination system, comprising the following steps:

[0038] (1) Filter the copper-containing etching liquid waste liquid overflowing from the circuit board etching process, and pump the clarified copper-containing etching waste liquid without solid particles into the electrolyte circulation tank for subsequent use; the etching waste liquid copper The content is 130g / l, the concentration of hydrochloric acid is 2.2N;

[0039] (2) Pump the filtrate obtained in step (1) into the electrowinning tank for electrowinning and copper removal; the voltage of the electrowinning tank is 1.5V, and the current density is 100A / m 2 ; The temperature of the electrowinning waste liquid is 30°C;

[0040] (3) The cathode copper obtained in step (2) (when the weight of copper reaches 20kg) is dried with compressed air after scalding, and packed into the warehouse; the scalding condition...

Embodiment 3

[0046] A method for electrodeposition and regeneration of copper-containing etching waste liquid in an acidic chlorination system, comprising the following steps:

[0047](1) Filter the copper-containing etching liquid waste liquid overflowing from the circuit board etching process, and pump the clarified copper-containing etching waste liquid without solid particles into the electrolyte circulation tank for subsequent use; the etching waste liquid copper The content is 160g / l, the concentration of hydrochloric acid is 2.5N;

[0048] (2) Pump the filtrate obtained in step (1) into the electrowinning tank for electrowinning and copper removal; the voltage of the electrowinning tank is 2.0V, and the current density is 500A / m 2 ; The temperature of the electrowinning waste liquid is 20°C;

[0049] (3) The cathode copper obtained in step (2) (when the weight of copper reaches 20kg) is dried with compressed air after scalding, and packed into the warehouse; the scalding condition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com