Water spraying type distribution hopper device for lattice type steel plate pile cofferdam

A technology of grid-type steel sheet piles and distribution buckets, which is applied in construction and infrastructure engineering, etc., can solve the problems of high stockpile height, uncompact filling, and high mud content, so as to reduce construction costs, reduce mud content, Effect of packing pressure equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described below in conjunction with the examples, and the examples are used to illustrate the present invention, and do not limit the present invention in any way.

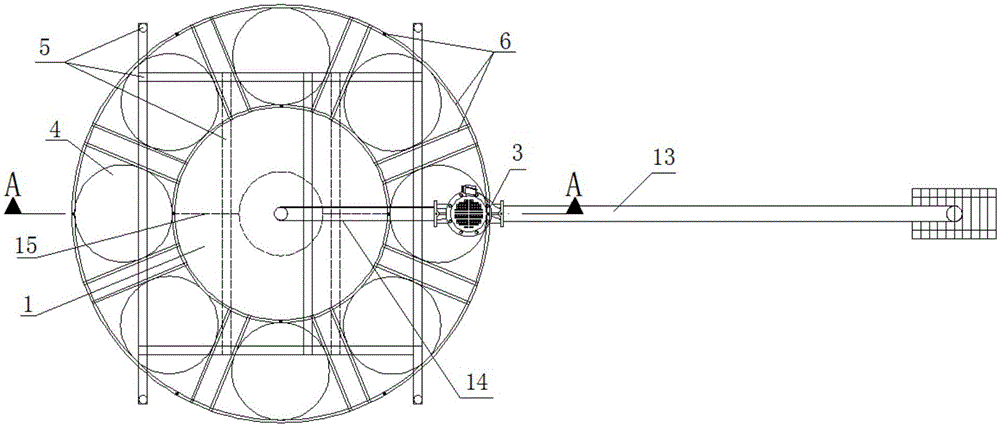

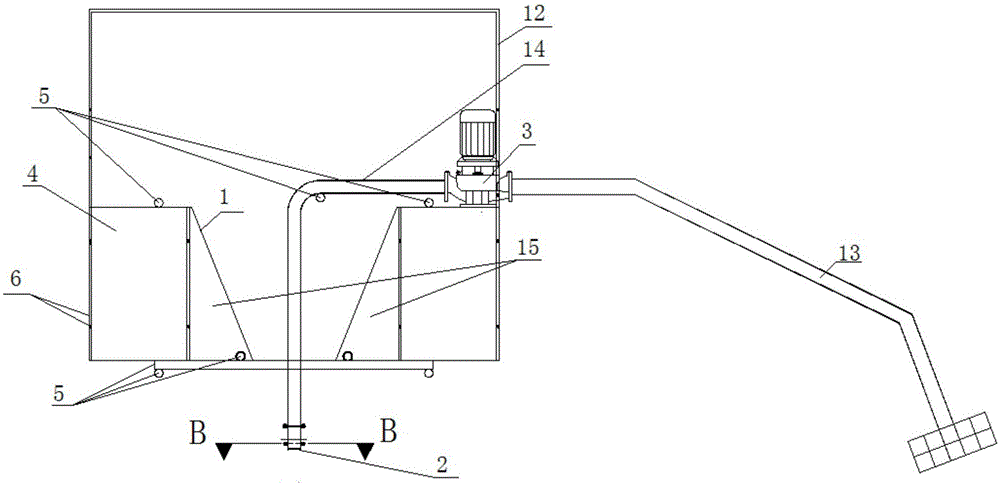

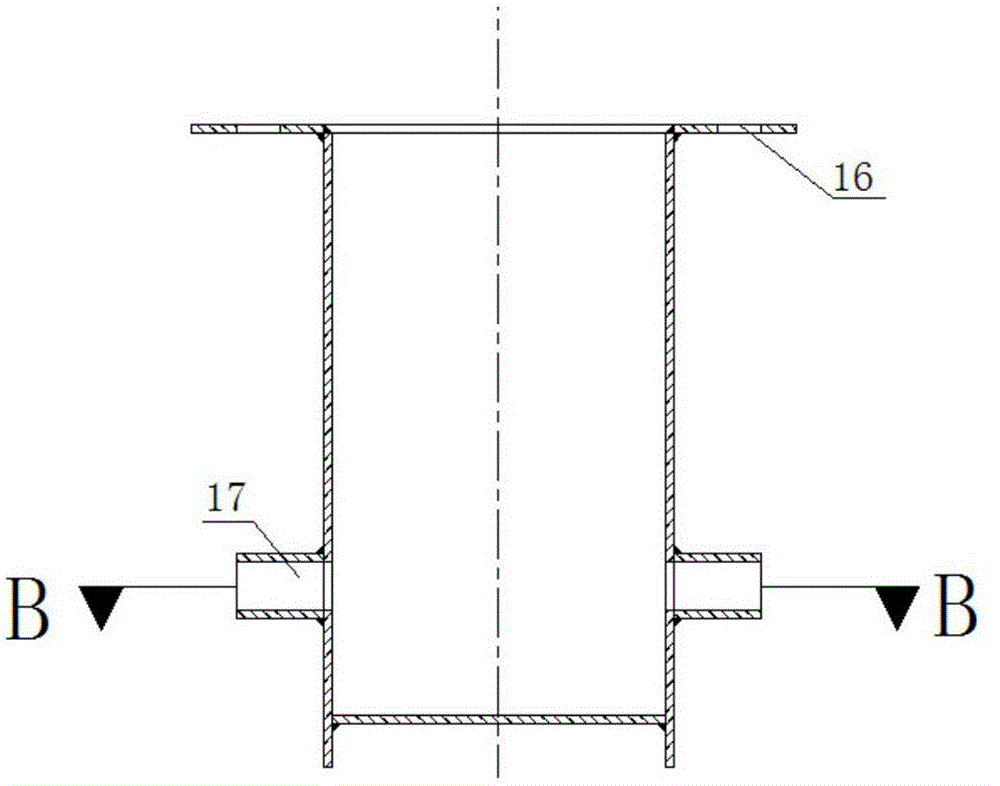

[0026] refer to Figure 1-Figure 5 , The present invention provides a lattice-type steel sheet pile cofferdam water spray distribution hopper device, the distribution hopper device is composed of a platform, a pumping and drainage system and a cone-shaped feeding funnel 1 .

[0027] The platform provides a hollow cavity for carrying the cone-shaped feeding funnel 1 , a position for placing and fixing the water pump 3 and the water pump outlet pipe 14 . The platform includes a floating body mechanism, a support for carrying a cone-shaped body feeding funnel 1 and a handrail 12.

[0028] The floating body mechanism comprises an empty oil barrel 4 and a steel bar circular frame. The empty oil barrels 4 are eight standard 200L iron empty oil barrels, and the eight iron empty o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com