Method for determining infiltration depth and infiltration capacity of protection agent on surface of cement-based material through fluorescent dye

A technology of cement-based materials and fluorescent dyes, which is applied in the field of reflecting the penetration amount and penetration depth of protective agents in surface-modified cement-based materials, and the penetration depth and penetration amount of protective agents, which can solve the cumbersome and accurate testing method of protective agent penetration depth. Insufficient degree of measurement and other problems, to achieve the effect of short measurement cycle, comprehensive measurement, and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

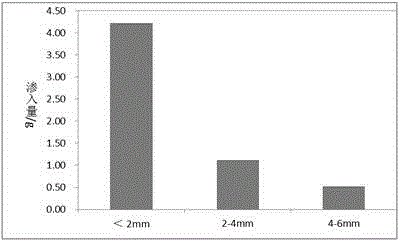

[0032] The water-cement ratio of the concrete used is 0.6, and the age is 1 year. The concrete has a relatively large pore size, and an obvious fluorescent signal can be detected with a small amount of fluorescent dye and protective agent mixed. The mixture of protective agent and fluorescent dye is defined as the test solution (the same below), the components of the test solution and their mass percentages are: fluorescent dye: 0.005%, protective agent 99.995%, and the fluorescent dye is rhodamine 6G, the protective agent is tetraethyl orthosilicate, and the protective agent and rhodamine 6G form a uniform solution.

[0033] The detection method is as follows: cut a columnar concrete test block with a diameter of 15cm into a columnar test block with a thickness of 2cm, seal the periphery of the test block with epoxy resin and soak it in the prepared test solution for half an hour. Take out the test piece and put it in a drying oven for 24 hours. After the sample is dried, us...

Embodiment 2

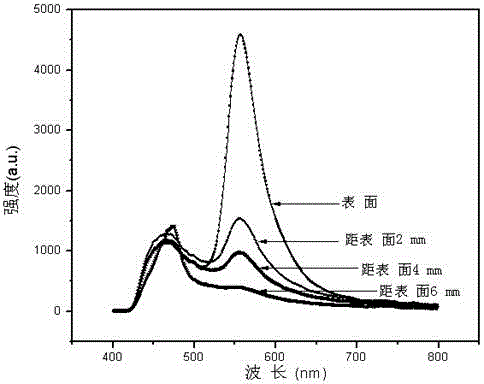

[0038] The concrete used has a water-cement ratio of 0.5 and an age of 10 years. The concrete has a long age and a relatively dense material structure. In order to detect the fluorescence spectrum more clearly, a slightly higher content of fluorescent dye is mixed with the protective agent. The components of the test solution in this embodiment and their mass percentages are: fluorescent dye: 0.01%, protective agent: 99.99%, the fluorescent dye is o-chlorophenyl fluorone, and the protective agent is tetraethyl orthosilicate.

[0039] The detection method is the same as in Example 1, except that samples are taken at the surface layer, 1mm, 2mm, 3mm, 4mm, and 5mm depth respectively. It can be seen from the fluorescence results that the penetration depth of the protective agent is 4mm. From the surface layer to 4mm away from the surface layer, the peak intensities of o-chlorophenylfluorone are: 6297.33, 3876.92, 1056.77, 769.72, 254.88, that is, the concentration ratio of ethyl o...

Embodiment 3

[0041] The concrete used has a water-cement ratio of 0.38 and an age of 20 years. The concrete has a small water-cement ratio, a long age, and a very small pore size. In order to detect an obvious fluorescence spectrum, it is necessary to mix a higher content of fluorescent dye with a protective agent. . The components of the test solution in this example and their mass percentages are: fluorescent dye: 0.03%, protective agent: 99.97%, the fluorescent dye is salicyl fluorone, and the protective agent is nano-SiO 2 Sol.

[0042] The detection method is the same as in Example 1, except that samples are taken at 0mm, 1mm, 2mm, 3mm, and 4mm from the surface layer. It can be seen from the fluorescence results that the penetration depth of the protective agent is 3mm. From the surface layer to 3mm away from the surface layer, the peak intensities of salicyl fluorone are: 8634.46, 4826.33, 847.69, 252.45 respectively, that is, the concentration ratio of the protective agent is 8634...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com