Method for cultivating clitocybe maxima through wormcast

A technology of cup mushroom and vermicompost, which is applied in the field of cultivating high-temperature edible fungi, can solve the problems of not being retrieved, and achieve the effects of reducing usage, increasing income, and making full use of it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] An example of the method of utilizing vermicompost to cultivate cup mushrooms of the present invention comprises the steps:

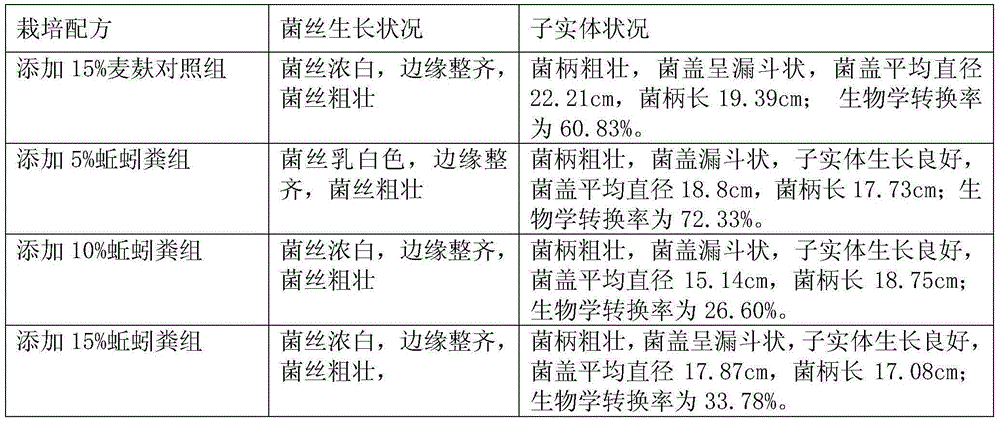

[0025] 1. After the vermicompost is dried in the sun, mash it completely, add 5%, 10%, and 15% to the tulip fungus cultivation material and mix well, and finally adjust the humidity to 65% and pH to 8.5.

[0026] 2. Bacteria bags with a specification of 26×15cm are used for bagging. The cultivation materials are suitable for tightness, and are sterilized by high-pressure steam at a temperature of 121°C for 4 hours.

[0027] 3. After the bacteria packs are cooled, inoculate the cultivars of cup mushrooms in the inoculation room with an inoculation amount of 8-10 g / pack.

[0028] 4. The bacteria bag grows under the conditions of humidity 60% and temperature 25°C until the bag is full.

[0029] 5. After the fungus bags are covered with fungus bags, move the fungus bags to the fruiting room for soil management. The thickness of the soil layer is 3cm...

Embodiment 2

[0037] In this embodiment, the tulip mushroom cultivation material is different from that in Example 1. The tulip mushroom cultivation material includes the following components and mass ratio: 75% mulberry branch, 1% calcium superphosphate, 1% gypsum powder, 1% lime, 20% vermicompost, all cultivation material components are the quality of dry matter, cultivation method is the same as embodiment 1. Under these cultivation conditions, the average diameter of the cup cap is 17.3 cm, the average length of the stipe is 16.8 cm, and its biological efficiency reaches 45.1%.

Embodiment 3

[0039] In this embodiment, the tulip mushroom cultivation material is different from that in Example 1. The tulip mushroom cultivation material includes the following components and mass proportions: 67% mulberry branch, 1% calcium superphosphate, 1% gypsum powder, 1% lime, 30% vermicompost, all cultivation material components are the quality of dry matter, cultivation method is the same as embodiment 1. Under this cultivation condition, the average diameter of the cap of the cup mushroom is 16.1 cm, the average length of the stipe is 14.8 cm, and its biological efficiency reaches 31.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com