Composite whitening composition, preparation and preparation method containing tea extract from Dianshan Mountain

A technology of tea extract and composition, applied in the field of daily chemicals, can solve the problems of dry skin, tingling, allergies, etc., and achieve the effects of easy addition, good compatibility, and inhibition of melanin production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

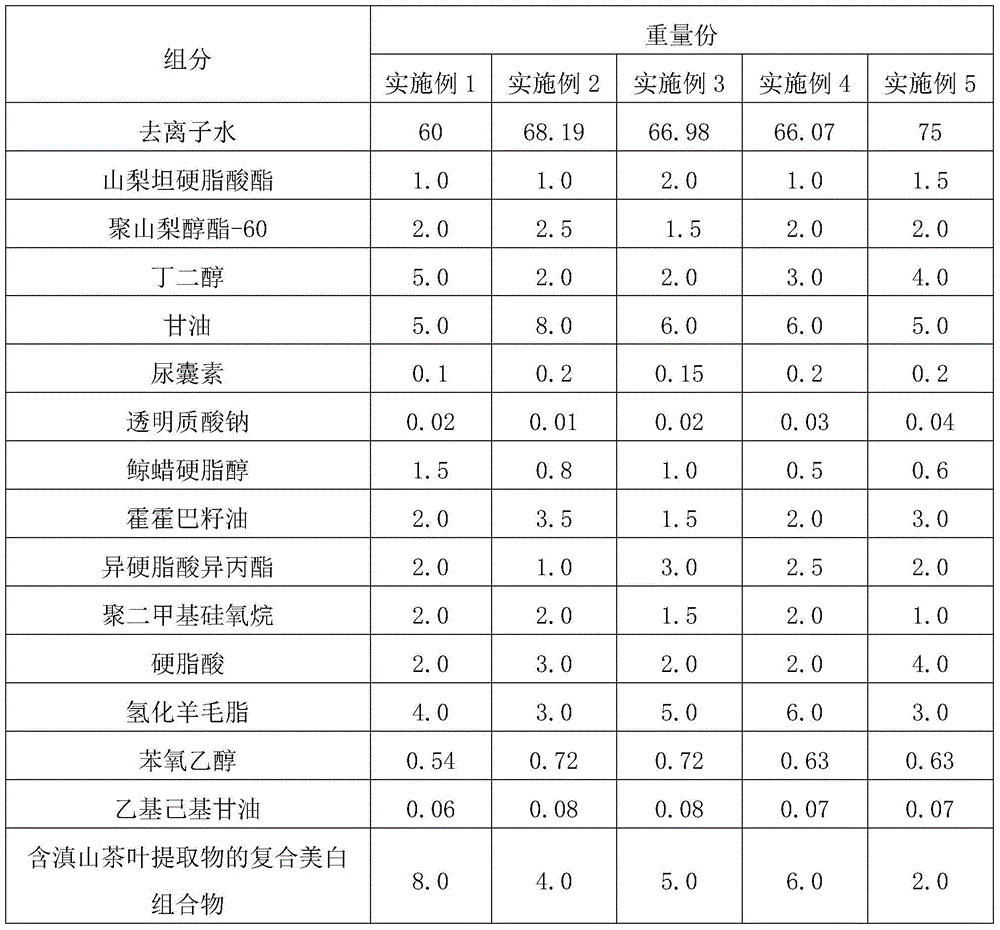

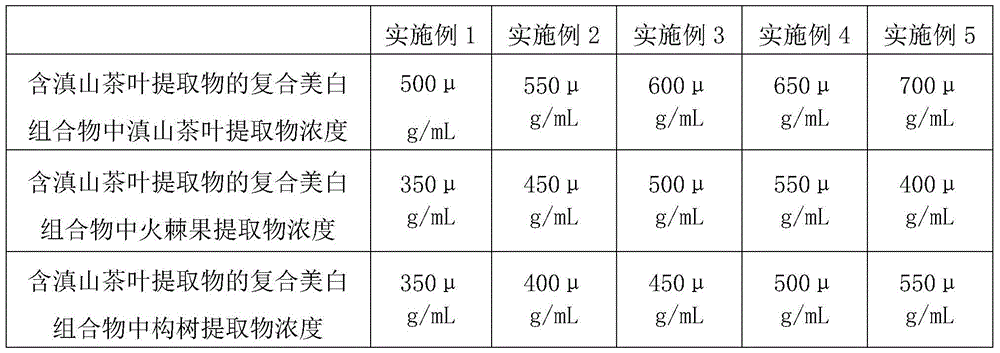

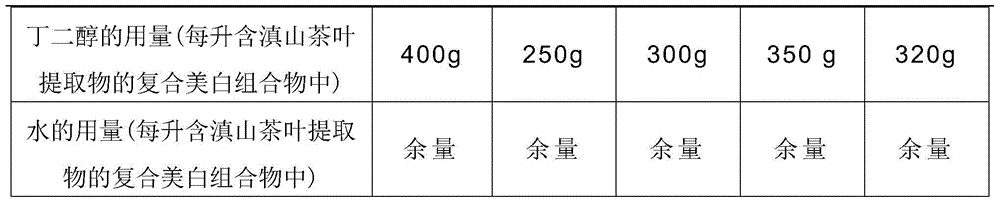

Examples

preparation example Construction

[0038] The preparation method of the compound whitening composition containing the Camellia yunnanensis tea extract in embodiment 1-embodiment 5 comprises the following steps:

[0039] The preparation of the tea extract of Mount Dian: crush the dried tea leaves of Mount Dian, extract 3 times under reflux with 75% ethanol, concentrate and remove the solvent, and obtain the tea extract of Mount Dian;

[0040] Preparation of Pyracantha extract: crush the dried Pyracantha, reflux extraction with 75% ethanol for 3 times, combine the extracts, and the extracts are subjected to macroporous resin column chromatography, eluting with ethanol with 70% ethanol as the mobile phase, Collect the 70% ethanol eluate, concentrate and remove the solvent to obtain the Acanthopanax extract;

[0041] Preparation of mulberry tree extract: crush the dried mulberry branches and leaves, reflux extraction with 75% ethanol for 3 times, combine the extracts, and the extracts are subjected to macroporous res...

Embodiment 1

[0043] Example 1 was prepared by the following method:

[0044] Heat the deionized water to 70°C, disperse the sodium hyaluronate with butanediol and add it into the deionized water, then add allantoin, glycerin and polysorbate-60, after the dissolution is complete, the water phase material is obtained, stand-by;

[0045] Then heat sorbitan stearate, cetearyl alcohol, jojoba seed oil, isopropyl isostearate, polydimethylsiloxane, stearic acid and hydrogenated lanolin to 70°C and melt After completion, the oil phase material is obtained and is ready for use;

[0046] Vacuumize the emulsification pot after preheating, use negative pressure to pump 2 / 3 volume of water phase materials into the emulsification pot, stir and homogenize, then use negative pressure to pump oil phase materials into the emulsification pot, and finally pump The remaining water-phase materials were kept homogenized at 70°C for 9 minutes, and then cooled by cooling water;

[0047] After cooling down to 44...

Embodiment 2

[0048] Example 2 was prepared by the following method:

[0049] Heat the deionized water to 75°C, disperse the sodium hyaluronate with butanediol and add it into the deionized water, then add allantoin, glycerin and polysorbate-60, after the dissolution is complete, the water phase material is obtained, stand-by;

[0050] Then heat sorbitan stearate, cetearyl alcohol, jojoba seed oil, isopropyl isostearate, polydimethylsiloxane, stearic acid and hydrogenated lanolin to 75°C and melt After completion, the oil phase material is obtained and is ready for use;

[0051] Vacuumize the emulsification pot after preheating, use negative pressure to pump 2 / 3 volume of water phase materials into the emulsification pot, stir and homogenize, then use negative pressure to pump oil phase materials into the emulsification pot, and finally pump The remaining water-phase materials were kept homogenized at 75°C for 11 minutes, and then cooled by cooling water;

[0052] After cooling down to 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com