Phosphoric-acid-functionalized carbon nano tubes (CNTs)-supported Pt catalyst for direct methanol fuel cell and preparation method of catalyst

A methanol fuel cell, carbon nanotube technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., to solve problems with poor stability and low current density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

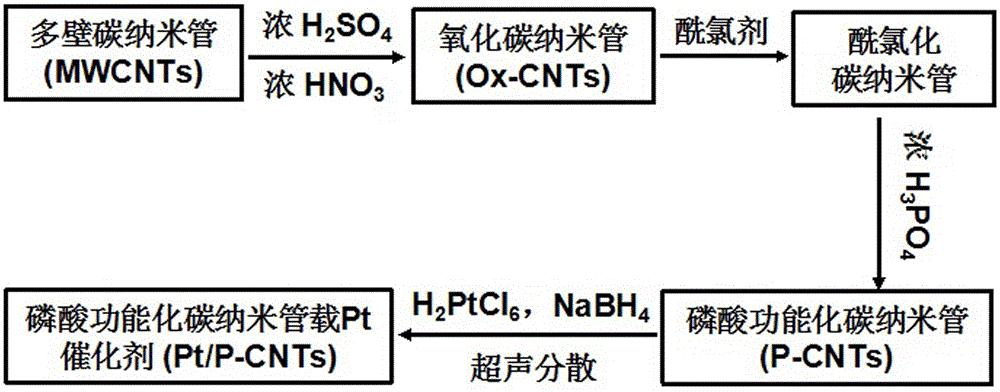

[0041] see figure 1 , a method for preparing a phosphoric acid functionalized carbon nanotube-supported platinum catalyst for a direct methanol fuel cell, comprising the steps of:

[0042] 1) Preparation of oxidized carbon nanotubes: add carbon nanotubes to concentrated sulfuric acid and concentrated nitric acid and stir, the stirring temperature is 30-80°C, and the reflux stirring time is 2-6 hours; then cool and dilute, filter with suction, wash with hydrochloric acid, Washing with water, drying in vacuum at a temperature of 70°C, to obtain oxidized carbon nanotubes;

[0043] Specifically, put 2.0g of CNTs in a 100mL round-bottomed flask, then add 30mL of concentrated sulfuric acid and 10mL of concentrated nitric acid and mix evenly. At 50°C, reflux with constant temperature magnetic stirring for 3 hours, naturally cool to room temperature, dilute with deionized water, and reduce Pressure suction filtration, washed with 5% hydrochloric acid solution, and then washed with de...

Embodiment 2

[0057] see figure 1 , a method for preparing a phosphoric acid functionalized carbon nanotube-supported platinum catalyst for a direct methanol fuel cell, comprising the steps of:

[0058] 1) At room temperature, put 2.0g of CNTs in a 100mL round-bottom flask, then add 40mL of concentrated sulfuric acid and 15mL of concentrated nitric acid and mix well. At 60°C, reflux with constant temperature magnetic stirring for 180 minutes, naturally cool to room temperature, and dilute with deionized water , filtered under reduced pressure, washed with 5% hydrochloric acid solution, and then washed with deionized water until neutral, until no SO 4 2- ions; dried under vacuum at 60°C to obtain oxidized carbon nanotubes, which are denoted as Ox-CNTs-2;

[0059] 2) Take 1.0g of carbon dioxide nanotubes and put them into a 100mL round bottom flask, add 40mL of oxalyl chloride, reflux and stir the reaction for 12 hours at 60°C, then distill and recover the excess oxalyl chloride at 100°C to...

Embodiment 3

[0064] see figure 1 , a method for preparing a phosphoric acid functionalized carbon nanotube-supported platinum catalyst for a direct methanol fuel cell, comprising the steps of:

[0065] 1) At room temperature, put 2.0g of CNTs in a 100mL round-bottomed flask, then add 30mL of concentrated sulfuric acid and 10mL of concentrated nitric acid and mix well. At 60°C, reflux with constant temperature magnetic stirring for 180 minutes, cool naturally to room temperature, and dilute with deionized water , filtered under reduced pressure, washed with 5% hydrochloric acid solution, and then washed with deionized water until neutral, until no SO 4 2- ion so far. Vacuum drying at 60°C to obtain oxidized carbon nanotubes and denote as Ox-CNTs-3;

[0066] 2) Add 500 mg of carbon dioxide nanotubes to a 100 mL round-bottomed flask, add 35 mL of oxalyl chloride, reflux and stir the reaction at 60°C for 24 hours, then distill and recover the excess oxalyl chloride at 100°C to obtain carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com