Leafing aluminum powder coated with modified film and preparing method thereof

A technology of surface coating and flake aluminum, applied in the direction of coating, etc., can solve the problems of cladding layer deformation, cladding layer peeling, aluminum surface roughness, etc., to reduce reflection, ensure reflection ability, and reduce specific emissivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

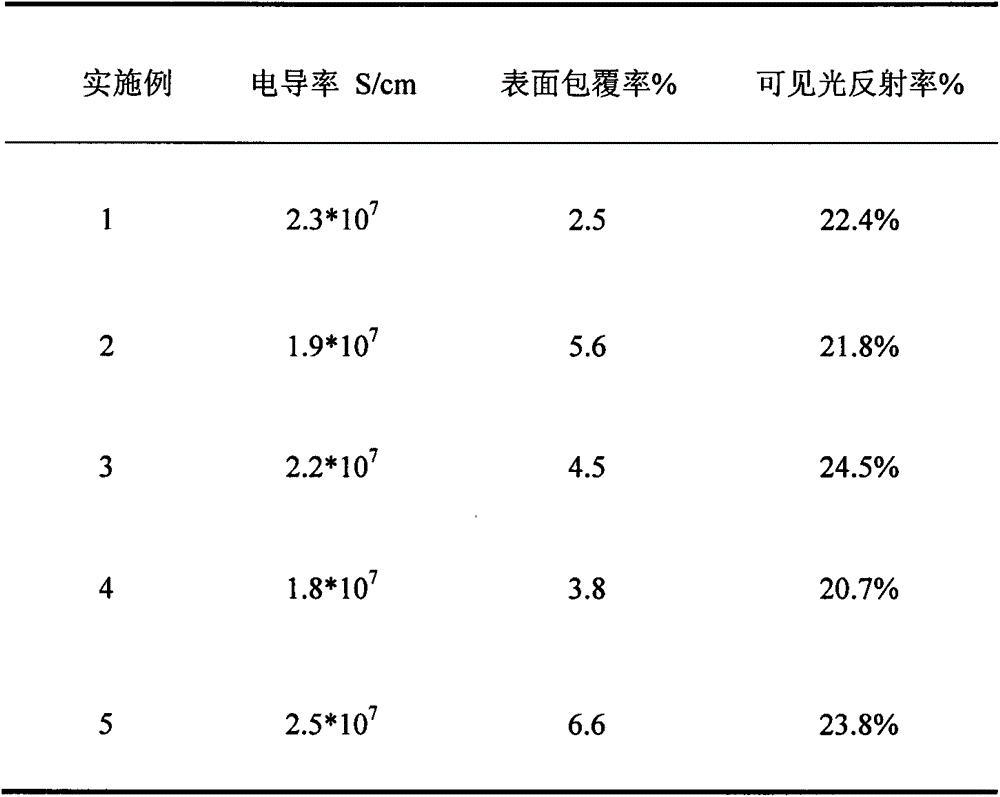

Examples

Embodiment 1

[0018] The preparation method of the flake aluminum powder coated with modified film on the surface of the present embodiment comprises the following steps:

[0019] ① Vacuumize the two evaporators, then pass in argon gas and fill the inner cavity of the evaporator; put the zinc powder and selenium powder into the two evaporators respectively, and heat the evaporator where the zinc powder is placed to 950 ° C ~ 1000 ° C, Zinc powder is gasified; the evaporator where the selenium powder is placed is heated to 720°C to 780°C, and the selenium powder is gasified. The gasified zinc and the gasified selenium are transported to the reaction chamber respectively by the argon gas flow, and the gasified zinc and the gasified selenium react in the inner cavity of the reactor to form zinc selenide. Zinc selenide is in a mist state in the reaction chamber. In another reactor, flake aluminum powder with a particle size of 30 μm to 60 μm is placed, and the reactor is vacuumed, and high-pre...

Embodiment 2

[0023] The preparation method of the flaky aluminum powder of the surface coated modified film of the present embodiment is the same as that of Example 1, except that:

[0024] The mass fractions of zinc powder, selenium powder and aluminum powder in step ① are respectively 0.65 parts of zinc powder, 0.87 parts of selenium powder and 152 parts of aluminum powder.

[0025] In step ①, heat the evaporator with zinc powder to 920°C to vaporize the zinc powder; heat the evaporator with selenium powder to 700°C to vaporize the selenium powder.

[0026] Step ② Depositing a ZnSe film on the surface of the aluminum powder with a thickness of 0.1-1.1 μm.

Embodiment 3

[0028] The preparation method of the flaky aluminum powder of the surface coated modified film of the present embodiment is the same as that of Example 1, except that:

[0029] In step ①, zinc powder is replaced by sulfur powder, and the mass fractions of zinc powder, sulfur powder, and aluminum powder are respectively 0.72 parts of zinc powder, 0.35 parts of sulfur powder, and 107 parts of aluminum powder.

[0030] In step ①, zinc powder and sulfur powder are melted and gasified at high temperatures of 940°C and 710°C respectively, and the zinc vapor reacts rapidly with the sulfur vapor to form zinc sulfide nanoparticles.

[0031] Step ② The aluminum powder is fully mixed and contacted with the mist zinc sulfide nanoparticles, so as to deposit a layer of ZnS film on the surface of the aluminum powder, and the thickness of the ZnS film is 0.2-2.3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com