Three-dimensional part printing method

A technology of 3D printing and parts, applied in the field of 3D printing parts, to achieve the effects of strong operability, meeting the preparation requirements, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

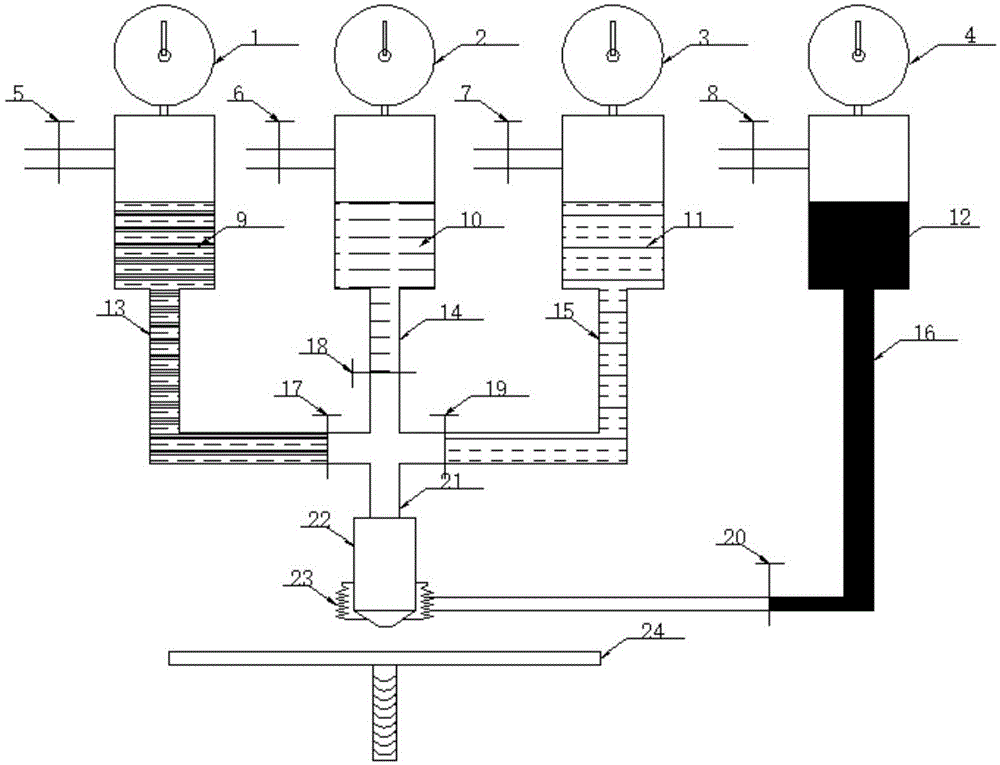

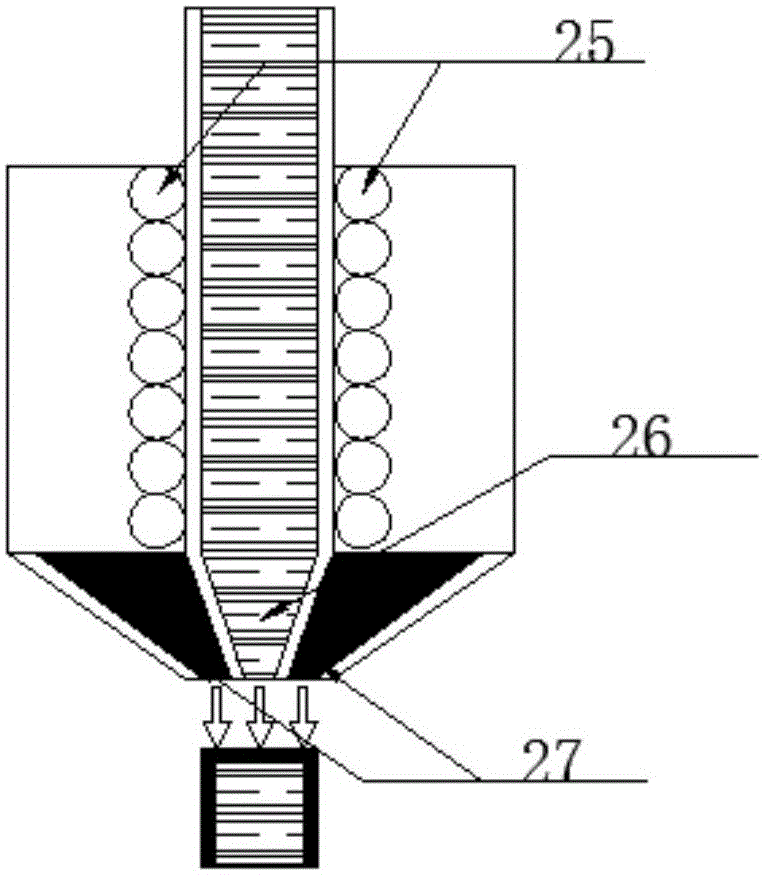

Method used

Image

Examples

preparation example Construction

[0067] The preparation process of metal slurry suitable for 3D printing includes: glue solution preparation and metal slurry preparation.

[0068] To prepare metal slurry suitable for 3D printing, it is necessary to solve the four major problems of solid-liquid compatibility (physical and chemical mutual compatibility), fluidity, solid phase content and curing time. Through practice, the following two (water-based and organic-based) gel system glues can be used to prepare qualified metal slurry. The preparation process is divided into two parts: glue solution preparation and metal slurry preparation.

[0069] Use two kinds of glue (water-based and organic-based gel system) to prepare metal slurry with low viscosity and high solid phase content as the raw material for 3D cold printing. The phase content is higher than 50 vol.%. The metal slurry should meet the performance requirements of 3D printing equipment such as pressure storage, pressure delivery, and rapid curing.

[0...

Embodiment 1

[0105] Implementation example 1: Using 3D cold printing technology to prepare cemented carbide end mills

[0106] 1. Preparation of cemented carbide slurry

[0107] Two liquids, 45wt.% hydroxyethyl methacrylate (HEMA) and 55wt.% toluene, were evenly stirred at room temperature to prepare a glue solution.

[0108] Add cemented carbide powder with a particle size of 5 μm into the organic glue, fully stir to make a metal slurry with a solid phase content of 50vol.%, add 0.01wt.% oleic acid as a dispersant, and add 0.2wt% of the slurry % N,N'-dimethylaniline is used as a catalyst, so that the viscosity of the slurry is 1 Pa·s, and the metal slurry is prepared.

[0109] benzoyl peroxide (BPO) as an initiator with 0.1 wt% of the slurry mass and 0.2 wt.% toluene as the slurry mass were stirred evenly at room temperature and used as a chemical curing agent for later use.

[0110] Remove air bubbles in 3D cold printing metal slurry and chemical curing agent by vacuum negative pressur...

Embodiment 2

[0118] Implementation example 2: Using 3D cold printing technology to prepare stainless steel ellipsoid parts

[0119] 1. Preparation of stainless steel slurry

[0120] Add 38wt.% N,N-dimethylbisacrylamide (MBAM) to 62wt.% acrylic acid and mix, then add deionized water with a total mass of acrylic acid and MBAM of 25wt.%, stir well at room temperature, and prepare Glue.

[0121] Add stainless steel powder with a particle size of 110 μm into the glue to make a metal slurry with a solid phase content of 60vol.%, add 0.02wt.% oleic acid as a dispersant to make the slurry viscosity 0.8Pa·s, add Hexamethylenetetramine (HMTA) adjusts the pH to 4, fully stirs at room temperature, and degasses under pressure to complete the preparation of the stainless steel slurry.

[0122] 2.3D cold printing stainless steel ellipsoid parison

[0123] According to the comprehensive consideration of the shrinkage ratio and solid content of stainless steel, the model is enlarged by 1.6 times the act...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com