Method for preparing high-purity great proportion spherical manganous-manganic oxide

A technology of trimanganese tetraoxide and spherical shape, which is applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of complex preparation process, high impurity content, irregular shape, etc., and achieve simplified process steps, high purity, and tap density big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

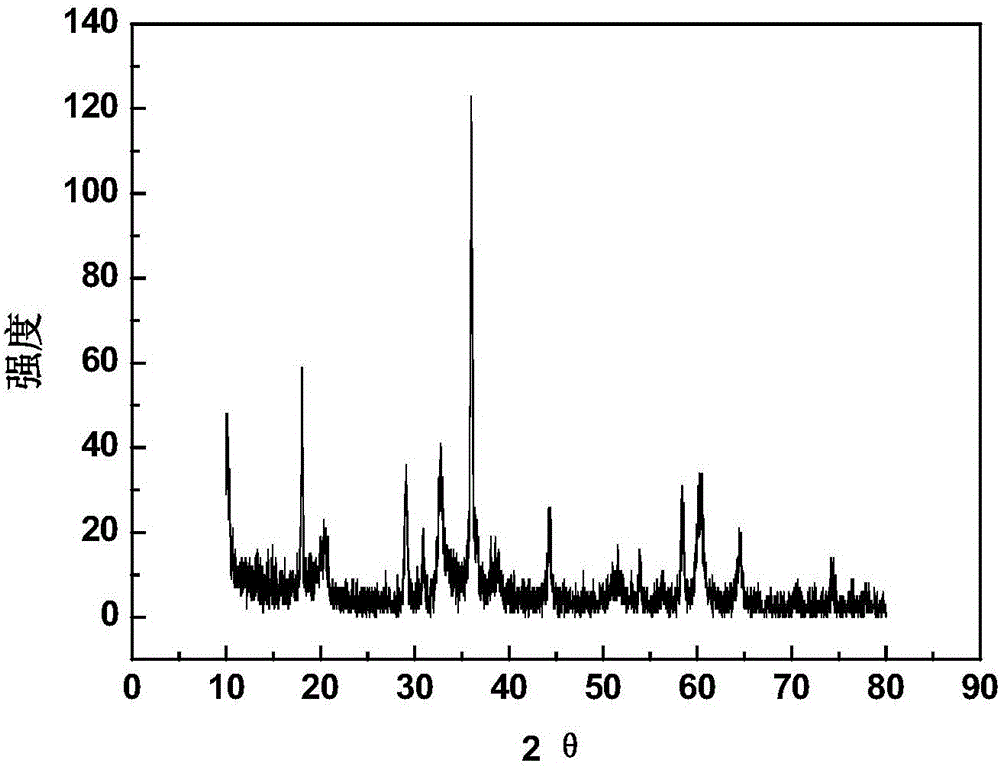

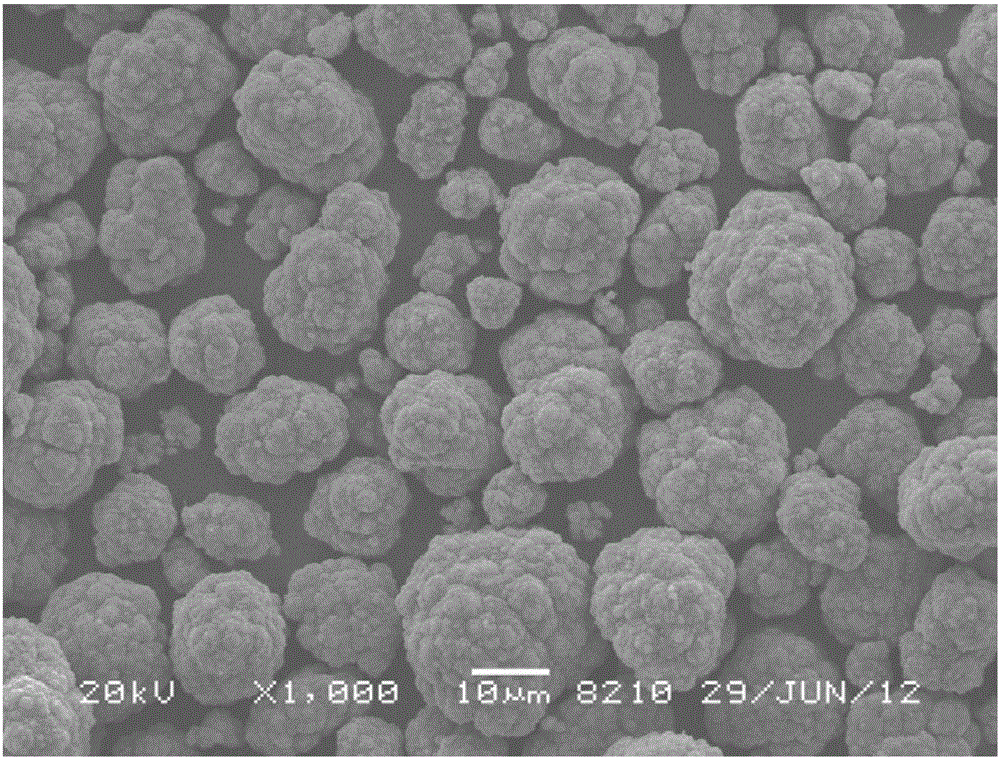

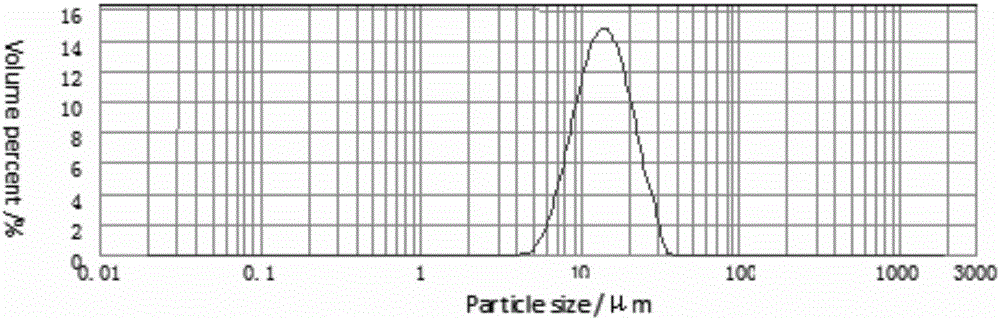

Embodiment 1

[0039] Prepare 20L of 1mol / L manganese sulfate solution, add 10gNa 2 S removes impurities, filters, and then adds 20g of ascorbic acid to the filtrate to dissolve, and 1.1mol / L of Na 2 CO 3 The solution is 20L, and the manganese sulfate solution and the manganese carbonate solution are sprayed into the vertical calciner at a flow rate of 5L / min by metering pumps, and the solution is reacted in the low temperature area (3 , the average particle size is in the range of 10 to 20 microns, and its elemental analysis shows that the Mn content of the trimanganese tetraoxide is 71.98%, the S content is 95ppm, the Fe content is 67ppm, and other metal impurities K, Na, Ca, The contents of Mg, Zn, Cu, Pb, Ni, and Co are 7ppm, 37ppm, 15ppm, 21ppm, 6ppm, 2ppm, 12ppm, 17ppm, and 11ppm, respectively.

Embodiment 2

[0041] Prepare 20L of 1.5mol / L manganese sulfate solution, add 12gNa 2 S removes impurity, filters, then adds 20g ascorbic acid to dissolve in the filtrate, the Na of 1.75mol / L 2 CO 3The solution is 20L, and the manganese sulfate solution and the manganese carbonate solution are sprayed into the vertical calciner at a flow rate of 10L / min by a metering pump, and the solution is reacted in the low temperature zone (3 , the average particle size is in the range of 10 to 20 microns, and its elemental analysis shows that the Mn content of the trimanganese tetraoxide is 71.96%, the S content is 97ppm, the Fe content is 65ppm, and other metal impurities K, Na, Ca, The contents of Mg, Zn, Cu, Pb, Ni, and Co are 7ppm, 42ppm, 16ppm, 19ppm, 9ppm, 5ppm, 11ppm, 21ppm, and 16ppm, respectively.

Embodiment 3

[0043] Prepare 20L of 2mol / L manganese sulfate solution, add 15gNa 2 S removes impurity, filters, then adds 20g ascorbic acid to dissolve in the filtrate, the Na of 2.4mol / L 2 CO 3 The solution is 20L, and the manganese sulfate solution and the manganese carbonate solution are sprayed into the vertical calciner at a flow rate of 7L / min by a metering pump, and the solution is reacted in the low temperature zone (3 , the average particle size is in the range of 10 to 20 microns, and its elemental analysis shows that the Mn content of the trimanganese tetraoxide is 72.01%, the S content is 78ppm, the Fe content is 56ppm, and other metal impurities K, Na, Ca, The contents of Mg, Zn, Cu, Pb, Ni, and Co are 7ppm, 35ppm, 13ppm, 15ppm, 12ppm, 7ppm, 13ppm, 25ppm, and 21ppm, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com