Industrial wastewater ultrasonic cooperative treatment and ultrasonic evaporative crystallization integrated technology and device

A technology for evaporative crystallization and industrial wastewater, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of not realizing the organic combination of process and evaporation process equipment, and in-depth research on ultrasonic evaporation Bottleneck, unfavorable industrial production and other problems, to achieve the effect of saving consumption rate, promoting energy exchange, and reducing the content of impurity components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

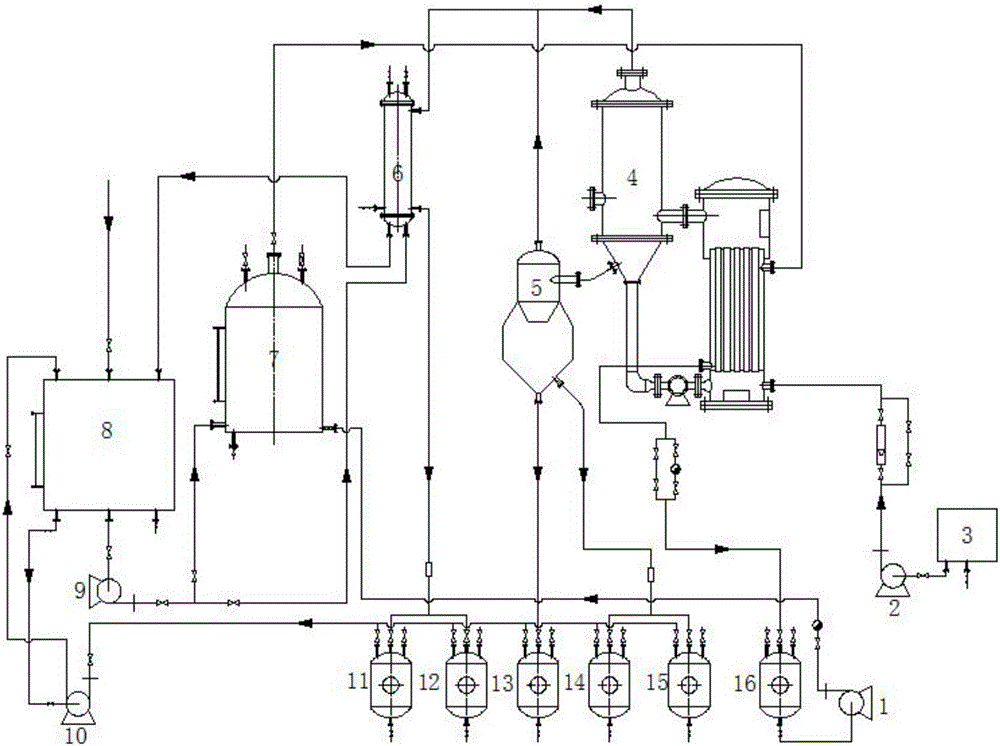

[0043] An integrated device for ultrasonic cooperative treatment of industrial wastewater and ultrasonic evaporation crystallization, which is composed of an ultrasonic cooperative wastewater pretreatment unit and a forced circulation ultrasonic evaporation crystallization unit.

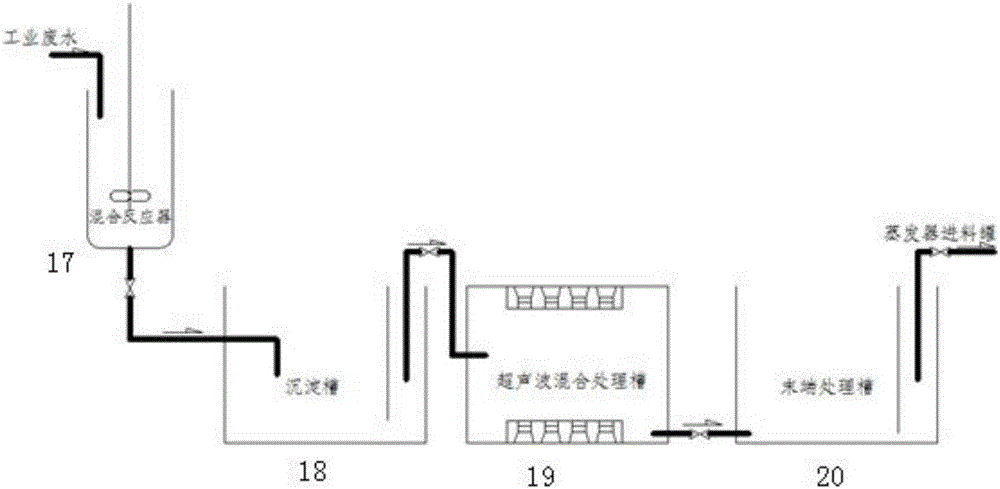

[0044] The ultrasonic cooperative wastewater pretreatment system consists of a mixing reactor 17, a sedimentation tank 18, an ultrasonic mixing treatment tank 19, and an end treatment tank 20, which are sequentially connected through liquid pipelines.

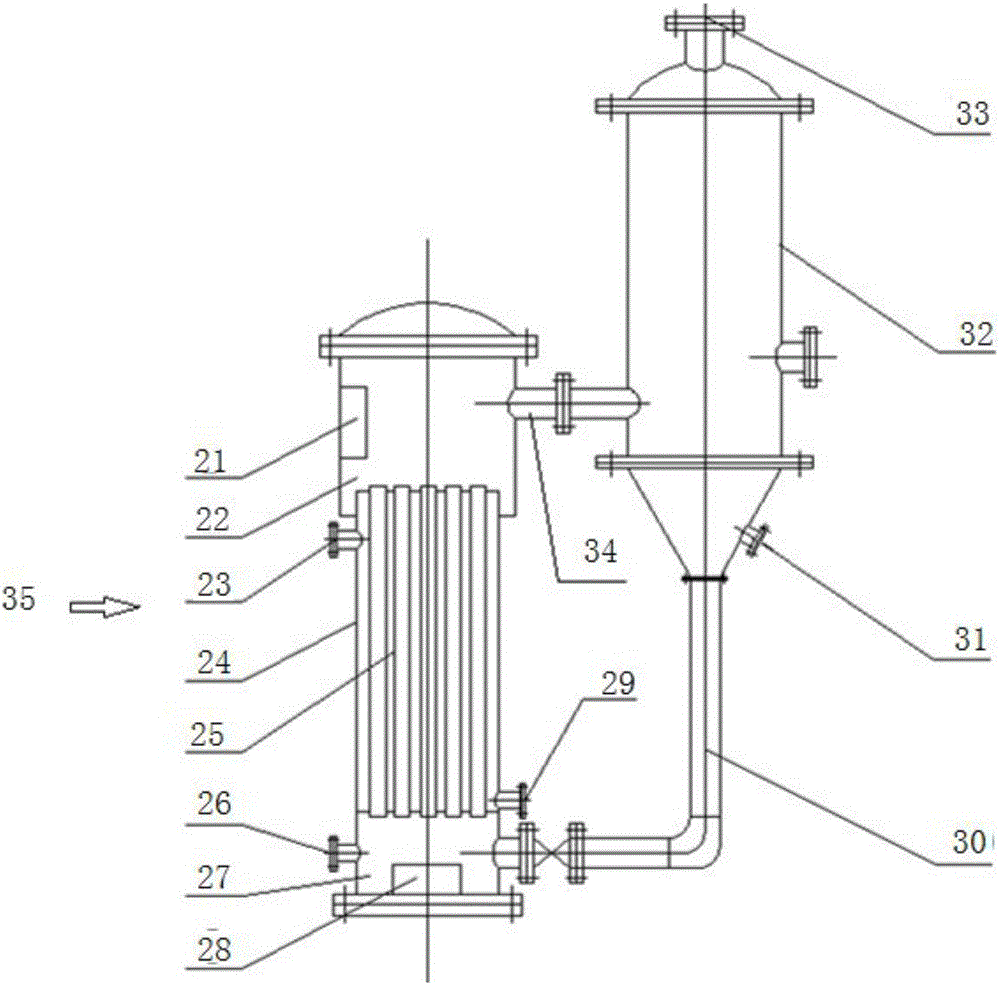

[0045] The forced circulation ultrasonic evaporation and crystallization unit consists of a preheating tank 3, a feed pump 2, a forced circulation ultrasonic evaporator 4, a crystallizer 5, a condenser 6, an atmosphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com