A kind of preparation method of starch-based hydration heat regulating material

A heat of hydration, starch-based technology, applied in the field of preparation of starch-based hydration heat regulating materials, can solve problems such as uncertain practicability and lack of dextrin, achieve control of structure and solubility, and reduce the peak value of heat release rate of hydration , Good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Preparation of enzymatic dextrin and its performance test

Embodiment 1-1

[0036] Add water to cornstarch to prepare starch milk with a mass fraction of 30%, heat it in a boiling water bath until it is completely gelatinized, and cool to room temperature. Adjust the pH to 5.5, add isoamylase and β-amylase for hydrolysis, the enzyme amount of isoamylase is 5U / g starch, the enzyme amount of β-amylase is 2U / g starch, and hydrolyze at 50°C After reacting for 5 hours, adjust the pH to below 3.0 to inactivate the enzyme for 30 minutes, then adjust the pH to neutral, and cool to room temperature; add ethanol with 40% volume of the reaction solution, stir for 30 minutes, filter, dry and pulverize the filtrate to obtain enzymatic dextrin .

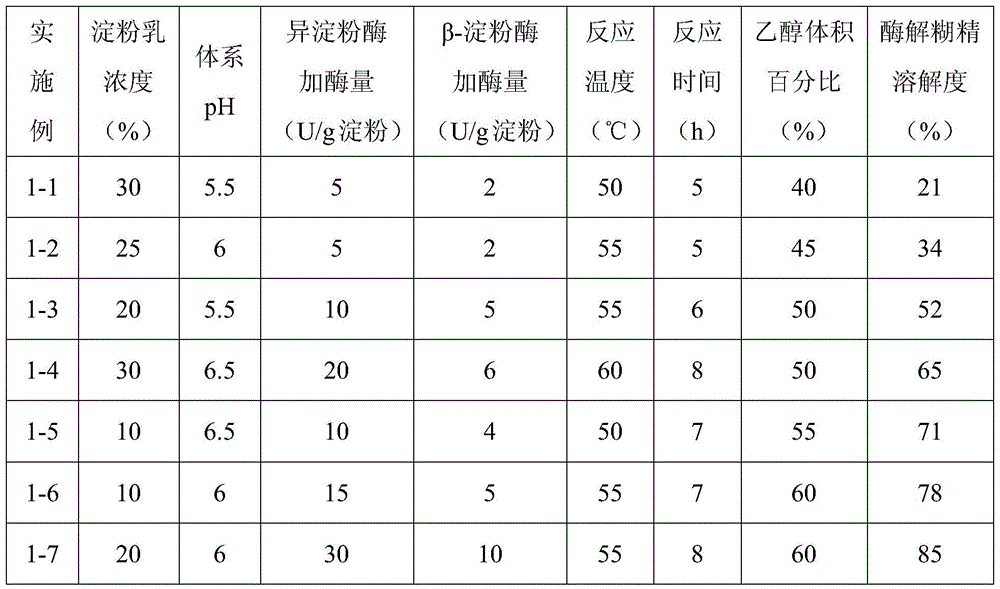

[0037] Examples 1-2 to 1-7 were prepared according to the steps of Example 1-1, and the main preparation process parameters and the solubility of the obtained enzymatic dextrin are shown in Table 1.

[0038] Table 1 Preparation process parameters of Examples 1-1 to 1-7 and the solubility of the obtained enzymatic dextrin...

Embodiment 2

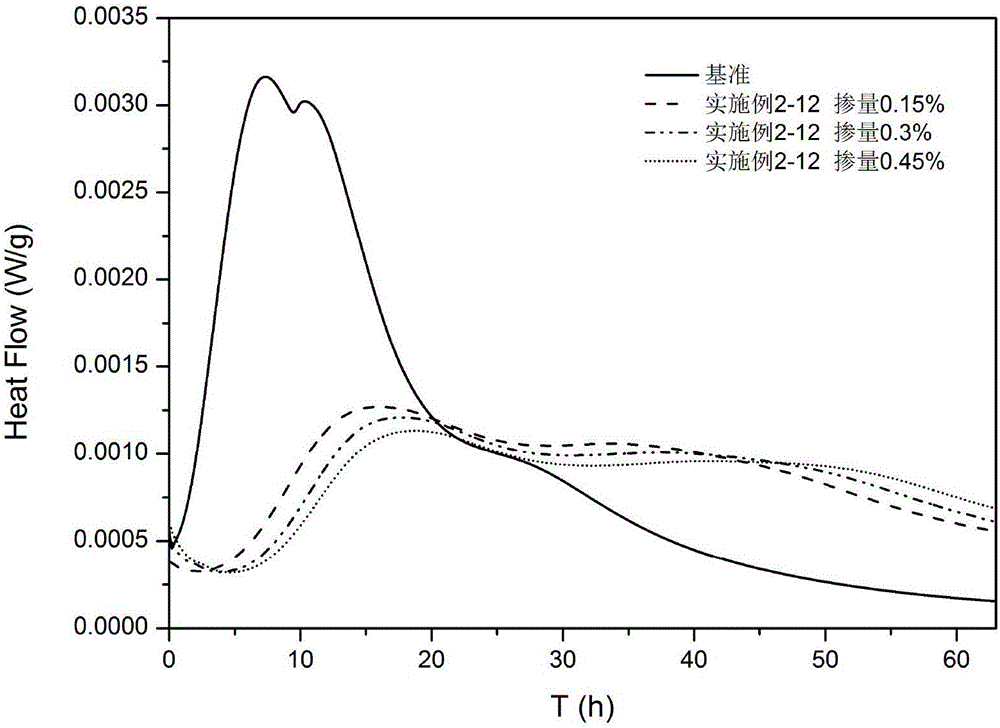

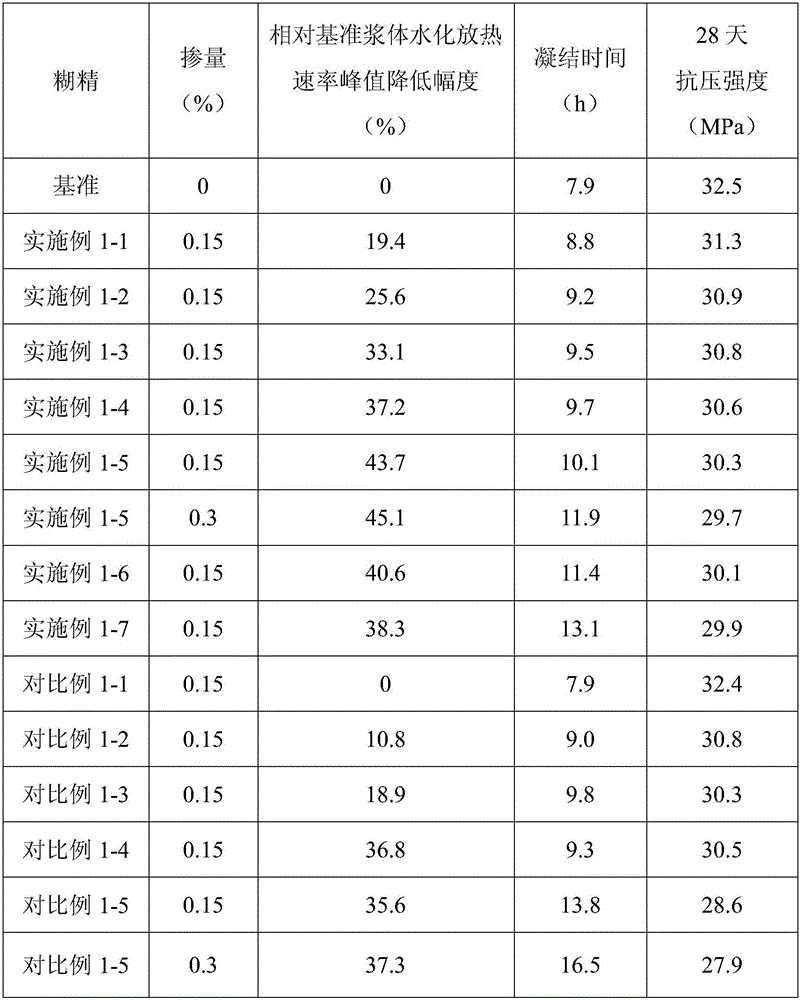

[0061] Example 2: Preparation of starch-based hydration heat regulation material and its performance test

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com