Tin methanesulfonate preparation method

A technology of tin methane sulfonate and methane sulfonic acid, applied in the chemical industry, can solve the problems of waste of precious metals, environmental pollution, loss of activity, etc., and achieve the effects of less equipment investment, no environmental pollution, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

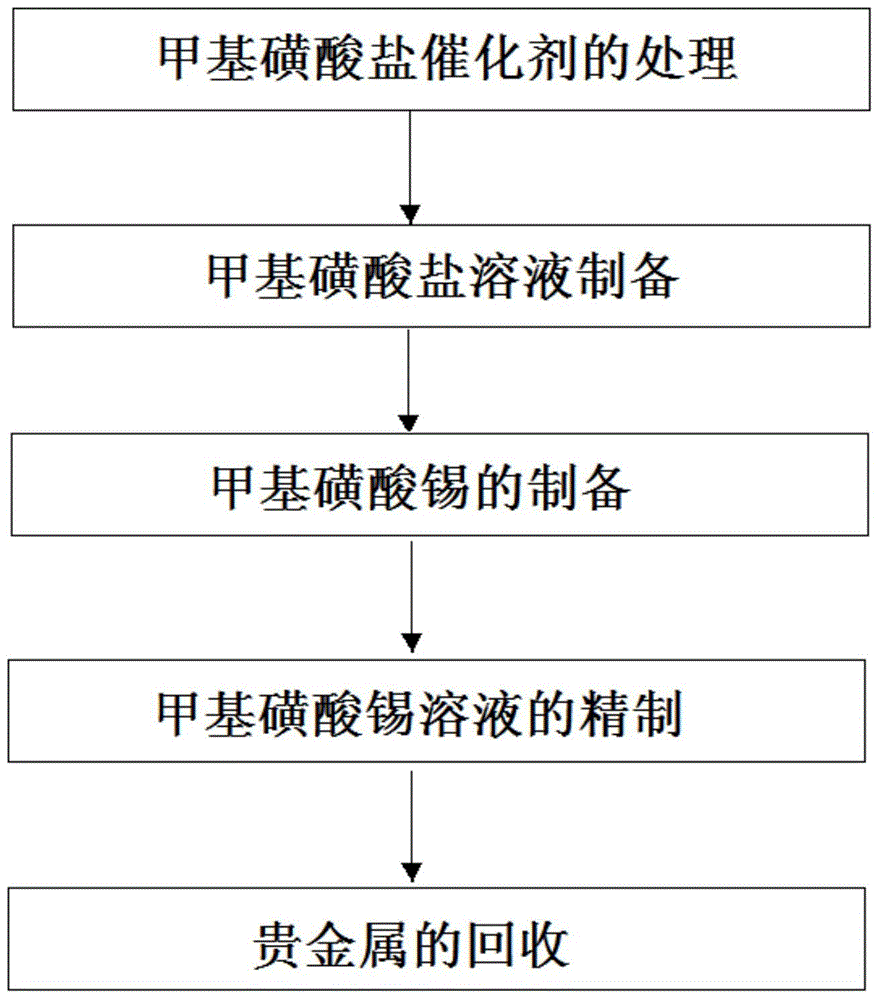

[0036] A method for preparing tin methanesulfonate, such as figure 1 As shown, including the following steps:

[0037] Take 200 grams of the copper methanesulfonate catalyst discarded after the synthesis of apple ester, wash it with ethanol several times, and evaporate to obtain 180 grams of organic copper methanesulfonate solid.

[0038] Dissolve the above-mentioned 180 grams of copper methanesulfonate solid in 655 grams of demineralized water, and add 65 grams of 70wt% methanesulfonic acid solution and 2.5 grams of resorcinol to prepare a 20wt% copper methanesulfonate solution. , Place the configured blue transparent liquid in a 2000mL anticorrosive container.

[0039] Put 200 grams of tin particles in the above copper methanesulfonate solution. And under vacuum conditions, constant stirring to make the displacement reaction proceed.

[0040] After 24 hours of reaction, the blue solution became a colorless solution, and gray-black powder was produced at the bottom of the reaction ...

Embodiment 2

[0042] A method for preparing tin methanesulfonate, such as figure 1 As shown, including the following steps:

[0043] Take 300 grams of the copper methanesulfonate catalyst discarded after the synthesis of apple ester, wash it with ethanol several times, and evaporate to obtain 256 grams of copper methanesulfonate solid without organic matter.

[0044] Dissolve the above-mentioned 256 grams of copper methanesulfonate solid in 931 grams of demineralized water, and add 90 grams of 70wt% methanesulfonic acid solution and 3 grams of resorcinol to prepare a 20wt% copper methanesulfonate solution , Place the configured blue transparent liquid in a 2000mL anticorrosive container.

[0045] Put 300 grams of tin particles in the copper methanesulfonate solution. And keep stirring to make the displacement reaction proceed.

[0046] After reacting for 20 hours, the blue solution became a colorless solution. At the same time, gray-black powder was produced at the bottom of the reaction vessel,...

Embodiment 3

[0048] A method for preparing tin methanesulfonate, such as figure 1 As shown, including the following steps:

[0049] Take 220 grams of discarded silver methanesulfonate catalyst, wash it with ethanol, etc., and evaporate to obtain 205 grams of silver methanesulfonate solid.

[0050] The above-mentioned silver methanesulfonate was dissolved in 470 g of demineralized water, while 95 g of 70 wt% methanesulfonic acid solution was added, and 2 g of resorcinol was added. Place the prepared silver methanesulfonate solution in a 1000ml glass container and stir to react. After 18 hours, the silver ion content in the test solution was less than 5 ppm. The reaction is over. 306 grams of 50.2 wt% tin methanesulfonate solution was obtained, and 105 grams of silver powder was recovered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com