Method for improving stability of salvianolic acid B

A salvianolic acid and stability technology, applied in the field of improving the stability of salvianolic acid B, can solve problems such as potential safety hazards and restrictions on the application of salvianolic acid B oral liquid preparations, and achieve low production costs, good thermal stability and chemical stability. Stability, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Mix the dried propylene glycol and choline chloride at a molar ratio of 2:1, heat and stir at 100°C for 6 hours to obtain a uniform transparent liquid, i.e. eutectic mixture; accurately weigh 2.13 mg of salvianolic acid B solution In 0.5ml eutectic mixture, seal the mixed solution, place it in a constant temperature water bath at 60°C and heat it. Samples were taken at 0, 3, 6, 9, and 12 hours, cooled rapidly, and the degradation rate of salvianolic acid B was determined to be 0.0273.

Embodiment 2

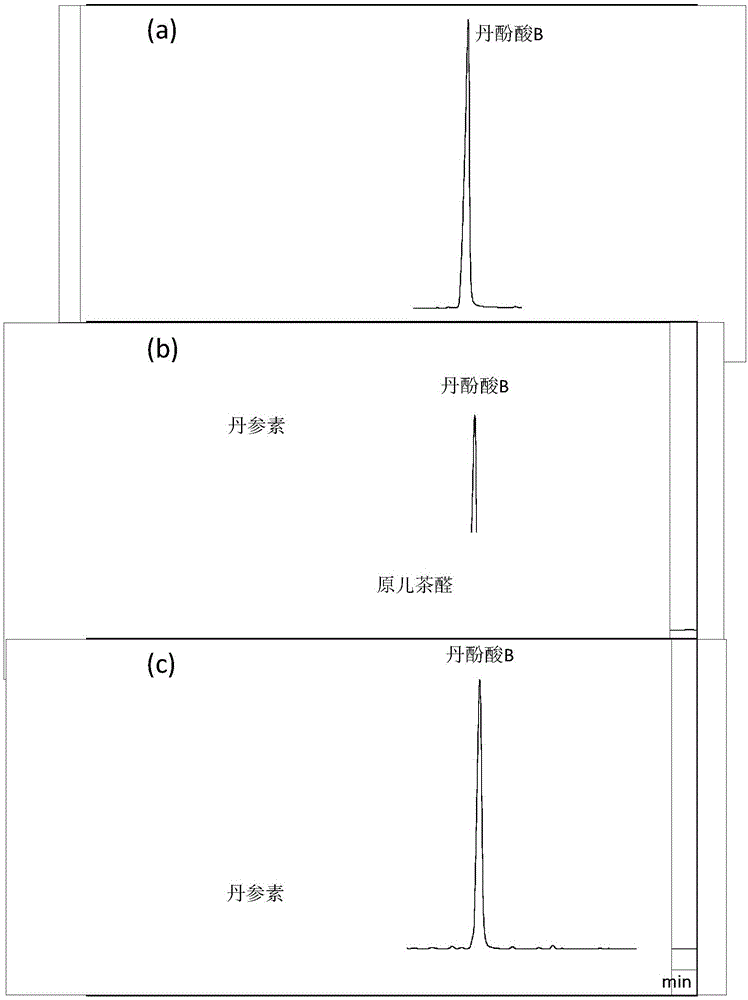

[0023] Mix the dried glycerol and choline chloride in a molar ratio of 4:1, heat and stir at 90°C for 8 hours to obtain a uniform and transparent liquid, i.e. eutectic mixture; accurately weigh salvianolic acid B1. 68mg was dissolved in 0.5ml eutectic mixture, the mixed solution was sealed and heated in a constant temperature water bath at 90°C. Samples were taken at 0, 3, 6, 9, and 12 hours, cooled rapidly, and the degradation rate of salvianolic acid B was determined to be 0.1027. The salvianolic acid B was dissolved in pure water and operated in parallel, and the degradation rate of salvianolic acid B was determined to be 0.2083. The chromatogram of salvianolic acid B and its degradation products is shown in figure 1 .

Embodiment 3

[0025] Mix the dried butanediol and choline chloride in a molar ratio of 2:1, heat and stir at 90°C for 10 hours to obtain a uniform transparent liquid, i.e. eutectic mixture; accurately weigh salvianolic acid B1. 47mg was dissolved in 0.5ml eutectic mixture, the mixed solution was sealed, and heated in a constant temperature water bath at 90°C. Samples were taken at 0, 3, 6, 9, and 12 hours, cooled rapidly, and the degradation rate of salvianolic acid B was determined to be 0.1674. The salvianolic acid B was dissolved in pure water and operated in parallel, and the degradation rate of salvianolic acid B was determined to be 0.2083.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com