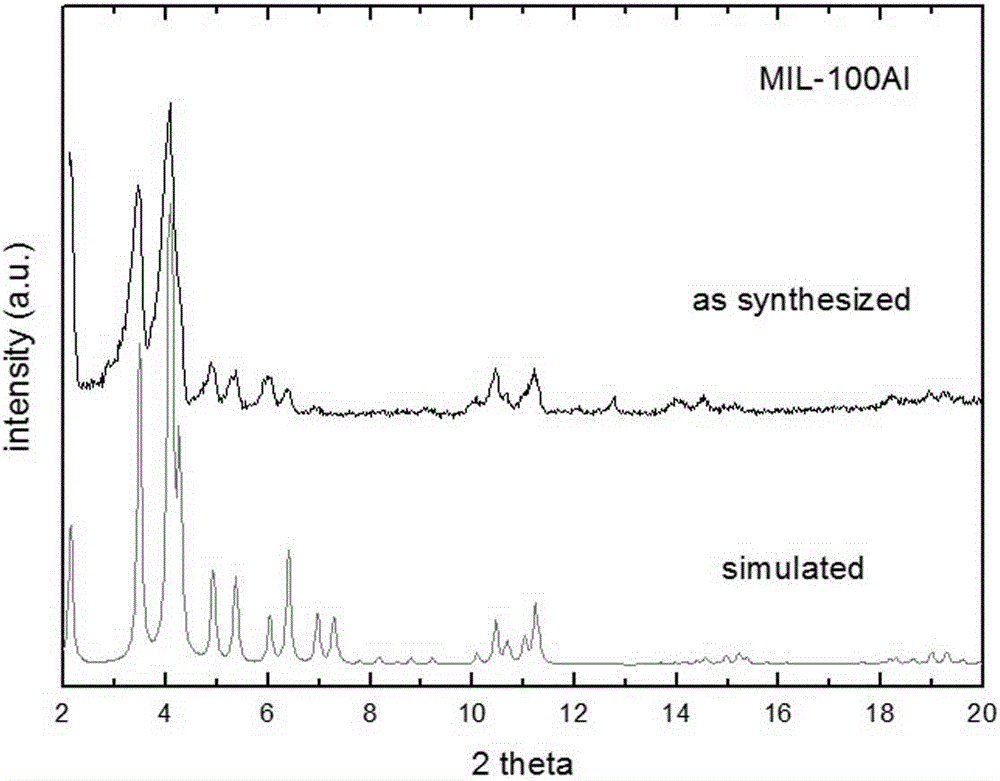

Method for directly compounding metal-organic framework material MIL-100A1 by using trimesic acid

A MIL-100A1, metal-organic framework technology, applied in the field of preparation of metal-organic framework material MIL-100A1, can solve the problems of harsh post-treatment process, high price, and cannot be removed by adjustment, so as to achieve no environmental pollution and accurate data. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the present invention in detail, the synthesis method of the present invention will be described below in conjunction with specific experimental procedures.

[0022] Chemical substances and materials: aluminum nitrate nonahydrate, tribenzoic acid, N, N dimethylformamide, nitric acid, and deionized water. The combined dosage is as follows: in grams and milliliters

[0023]

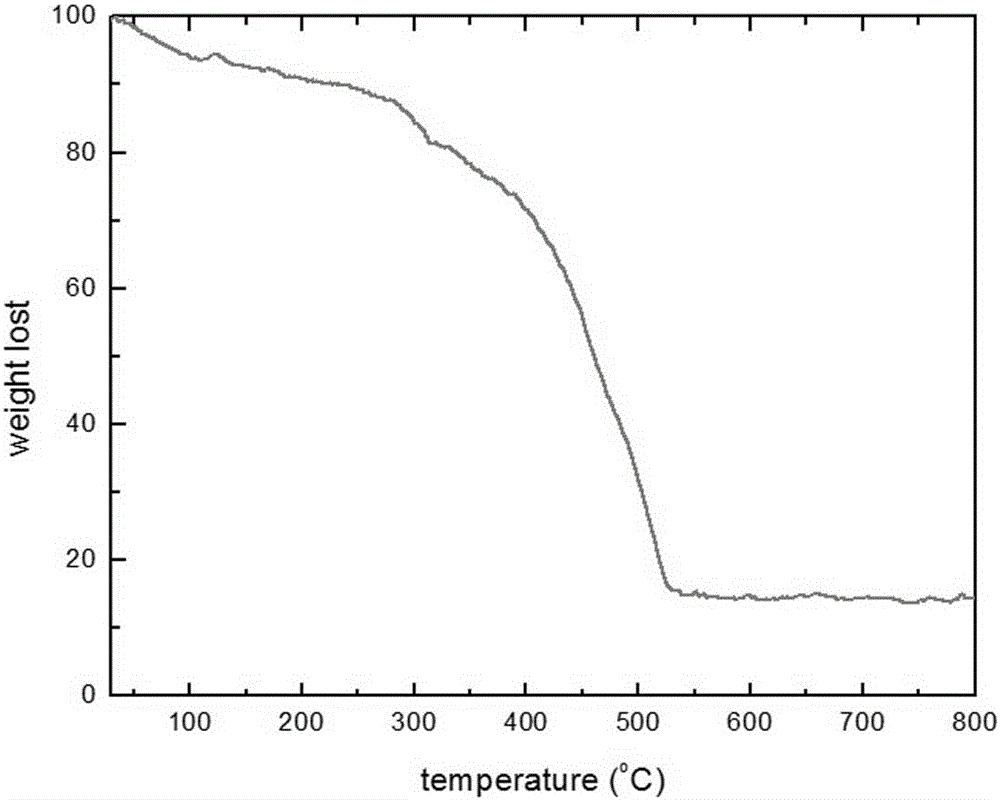

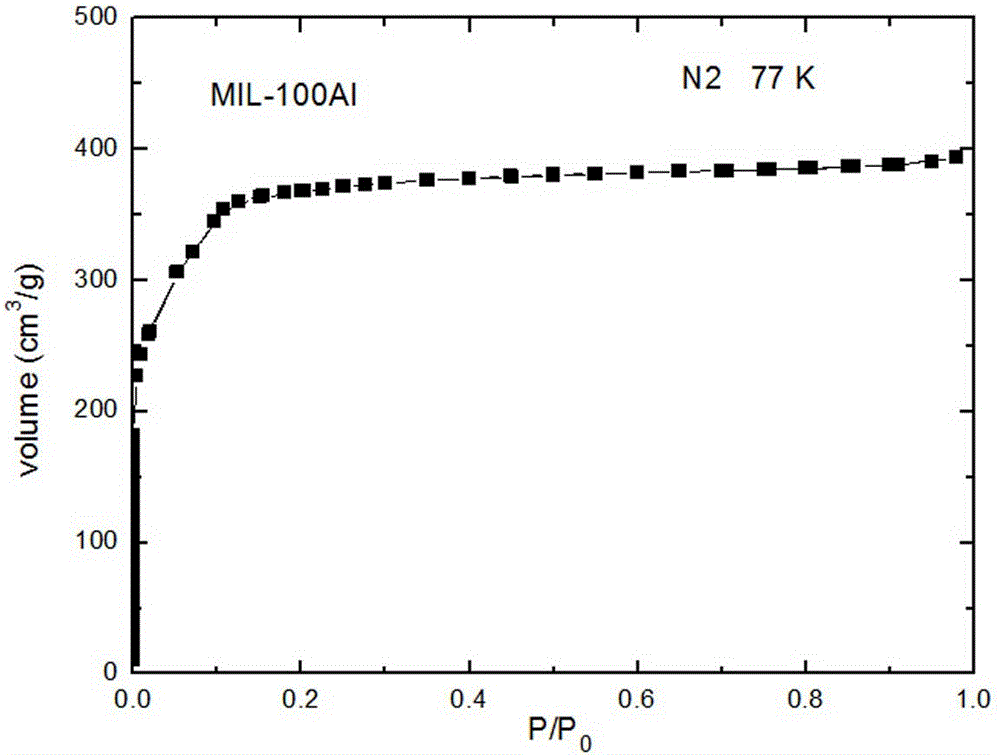

[0024] A method utilizing trimesic acid to directly synthesize metal-organic framework material MIL-100A1, the steps of which are:

[0025] (1) prepare 1mol / L dilute nitric acid standard aqueous solution

[0026] Measure 69.2mL±0.2mL of 65% concentrated nitric acid, add it to a 1000mL volumetric flask, measure deionized water and add it into the volumetric flask, and when the liquid level reaches the 1000mL mark, it becomes a 1.0mol / L dilute nitric acid aqueous solution.

[0027] (2) Hydrothermal synthesis of MIL-100Al crystal material

[0028] The synthesis of MIL-100Al cry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com