Ultra wear-resistant nanomaterial modified phenolic resin and preparation method thereof

A technology of nano-materials and phenolic resins, which is applied in the field of ultra-wear-resistant nano-materials modified phenolic resins and its preparation, can solve the problems of poor heat resistance, poor toughness, and high brittleness, and improve mechanical properties and thermal stability. , Improve the effect of modification and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

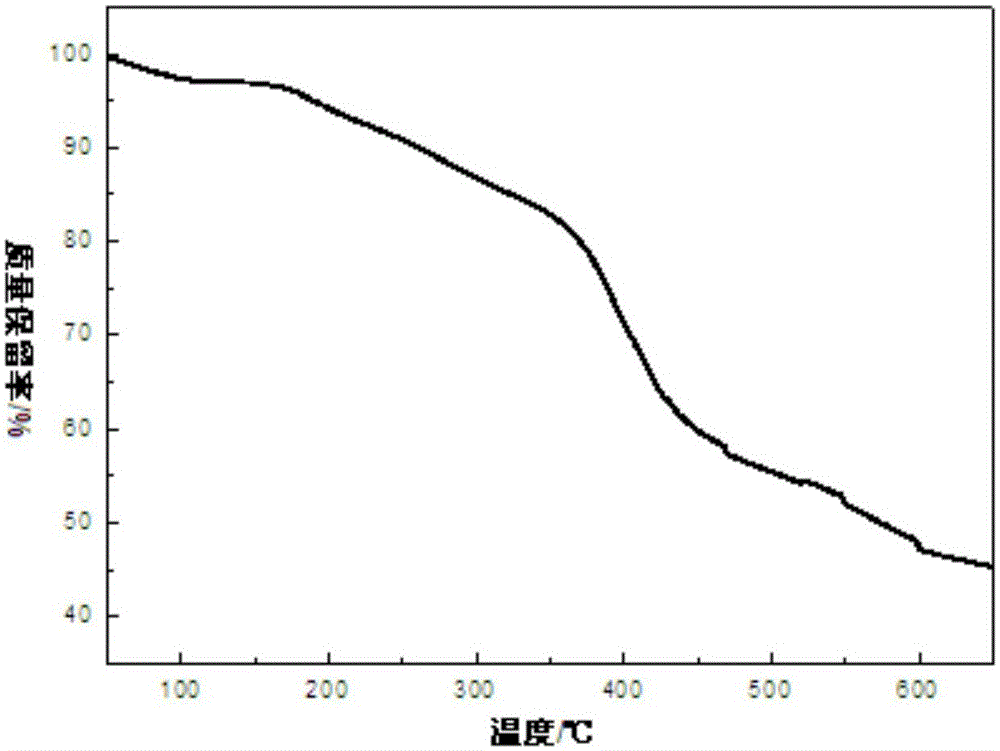

Embodiment 1

[0028] A super wear-resistant nano material modified phenolic resin, prepared by the following method: adding 10 parts of organic solvent, 10 parts of silane coupling agent, 25 parts of nano ZrO 2 Put it into a stirred tank, at room temperature, after mechanical stirring for 1.5h, add it to a ball mill for ball milling (ball milling speed 300rpm, ball-to-material ratio 4:1), and finally enter an ultrasonic reactor for 0.5h (ultrasonic power is 3KW) to obtain the surface Modified Nano ZrO 2 Suspension, add 100 parts of phenolic resin to the suspension, stir well for 0.5h, then enter the ultrasonic reactor for 0.1h (ultrasonic power 3KW), vacuum dry, crush the material to 200 mesh, and obtain a super wear-resistant Nano-ZrO 2 Modified phenolic resin. The TG figure of the modified phenolic resin prepared in this embodiment is shown in figure 1 .

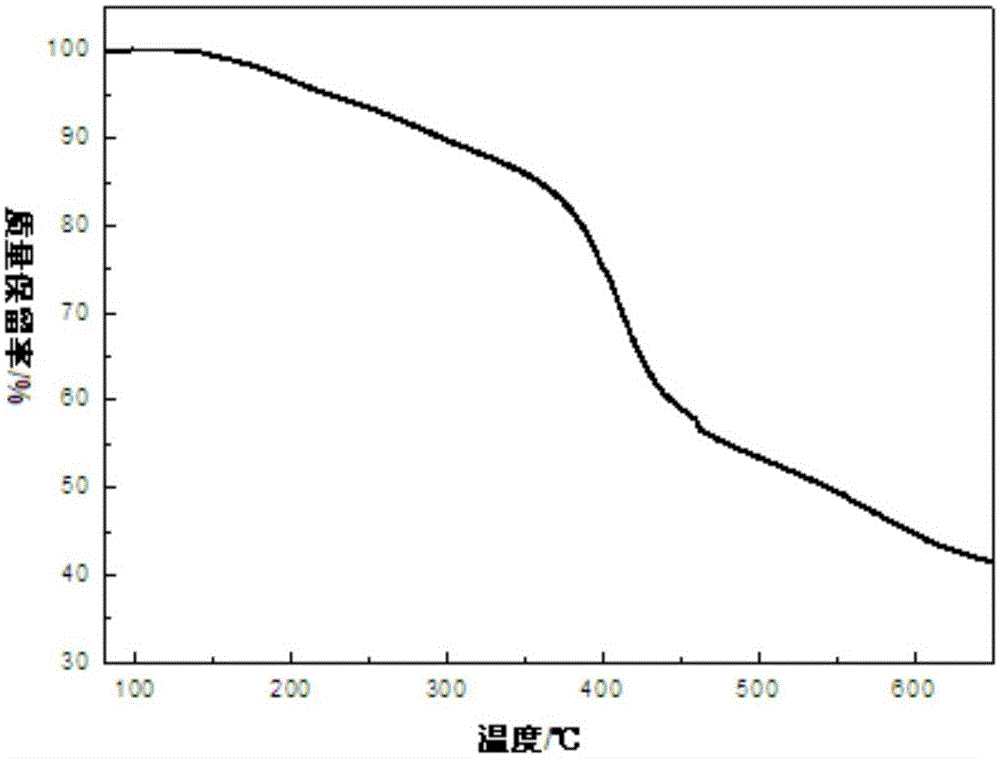

Embodiment 2

[0030] A super wear-resistant nano-material modified phenolic resin, prepared by the following method: adding 1000 parts by mass of organic solvent, 20 parts of titanate coupling agent, 20 parts of polyethylene glycol, 10 parts of oleic acid , 10 parts of nano-ZnO into the stirred tank, at room temperature, mechanically stirred for 0.5h, then added to the ball mill for ball milling (rotating speed 500rpm, ball-to-material ratio 3:1), and finally entered the ultrasonic reactor for 1h (ultrasonic power 2KW) , to obtain a surface-modified nano-ZnO suspension, add 100 parts of phenolic resin to the suspension, fully stir for 0.1h, enter an ultrasonic reactor for treatment for 1h (ultrasonic power is 2KW), vacuum dry, and crush the material to 200 meshes. That is to obtain a super wear-resistant nano ZnO modified phenolic resin. The TG figure of the modified phenolic resin prepared in this embodiment is shown in figure 2 .

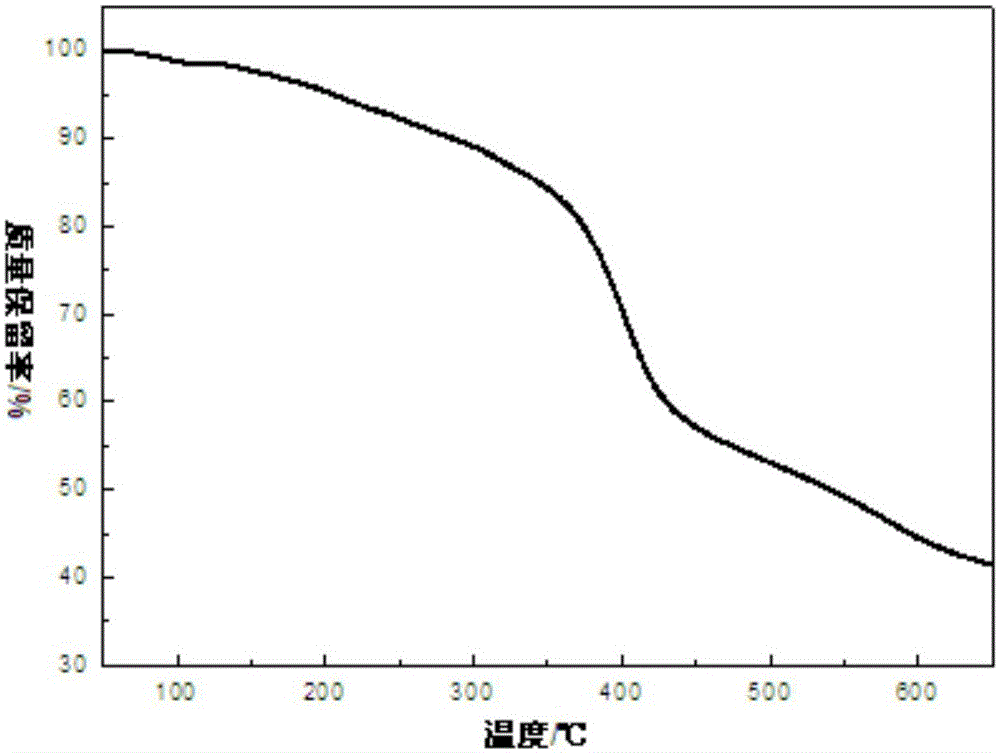

Embodiment 3

[0032] A super wear-resistant nano-material modified phenolic resin, prepared by the following method: adding 500 parts by mass of organic solvent, 30 parts of zirconium coupling agent, 30 parts of polyethylene glycol, and 40 parts of monoolefin Butylenediamine, 12 parts of nano-SiO 2 13 parts of nano-SiC into the stirred tank, at room temperature, mechanically stirred for 3 hours, then added to the ball mill for ball milling (rotational speed 800rpm, ball-to-material ratio 2:1), and finally entered the ultrasonic reactor for 2 hours (ultrasonic power 0.5KW), Surface-modified nano-SiO 2 / SiC suspension, add 100 parts of phenolic resin to the suspension, stir well for 1 hour, then put it into an ultrasonic reactor for 2 hours (ultrasonic power 0.5KW), vacuum dry, crush the material to 200 mesh, and obtain a super-resistant Grinding nano-SiO 2 / SiC modified phenolic resin. The TG figure of the modified phenolic resin prepared in this embodiment is shown in image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com