Asphalt-based material, preparation method and application of asphalt-based material

An asphalt-based, emulsified asphalt technology, applied in building thermal insulation materials, building components, pavement details, etc., can solve problems such as complex preparation processes, and achieve the effect of simple construction and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

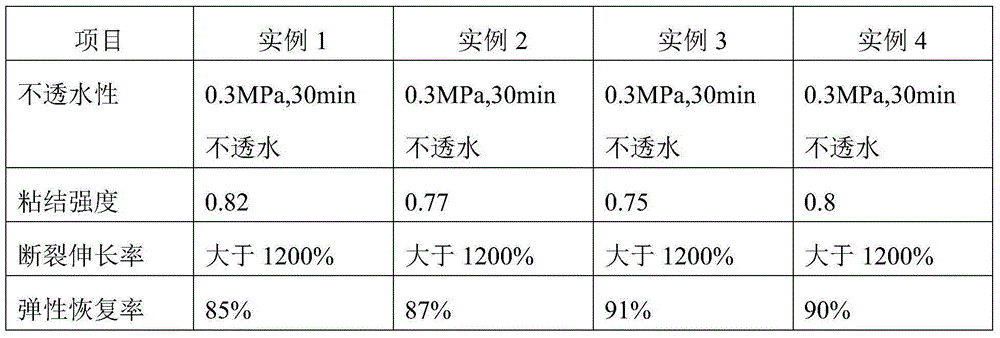

Examples

Embodiment 1

[0031] Preparation of component A:

[0032] The emulsified asphalt is commercially available anionic emulsified asphalt, the average volume particle size is less than 10 μm, and the fine material is made of carbon black and calcium powder at a mass ratio of 1:2. When heating 60% emulsified asphalt with a solid content of 65% to 35°C while stirring, add 2% fine material and 2% anionic dispersant, then slowly add 36% rubber latex with a solid content of 42% at a temperature of 40°C , and stir evenly to obtain component A.

[0033] Preparation of component B:

[0034] Calcium chloride 98% and sodium chloride 2% are dissolved in water by mass, stirred evenly to prepare a mixed solution with a concentration of 5%.

[0035] After mixing and curing component A and component B at a mass ratio of 5:1, an asphalt-based material that can quickly repair cracks in asphalt pavement is obtained.

Embodiment 2

[0037] Preparation of component A:

[0038] The emulsified asphalt is commercially available anionic emulsified asphalt, the average volume particle size is less than 10 μm, and the fine material is made of carbon black and calcium powder at a mass ratio of 1:2. Heat emulsified asphalt 65% with a solid content of 68% to 40°C while stirring, add 2% fine material and 2% anionic dispersant with stirring, and then slowly add 31% rubber latex with a solid content of 46% at a temperature of 45°C , and stir evenly to obtain component A.

[0039] Preparation of component B:

[0040] Calcium chloride 99.5% and sodium chloride 0.5% are dissolved in water by mass, stirred evenly to prepare a mixed solution with a concentration of 20%.

[0041]After mixing and curing component A and component B at a mass ratio of 8:1, an asphalt-based material that can quickly repair cracks in asphalt pavement is obtained.

Embodiment 3

[0043] Preparation of component A:

[0044] The emulsified asphalt is commercially available anionic emulsified asphalt, the average volume particle size is less than 10 μm, and the fine material is made of carbon black and calcium powder at a mass ratio of 1:2. Heat emulsified asphalt 60% with a solid content of 62% to 30°C while stirring, add 2.5% fine material and 1.5% anionic dispersant with stirring, and then slowly add 36% rubber latex with a solid content of 50% at a temperature of 35°C , and stir evenly to obtain component A.

[0045] Preparation of component B:

[0046] Calcium chloride 98.5% and sodium chloride 1.5% are dissolved in water by mass, stirred evenly to prepare a mixed solution with a concentration of 15%.

[0047] After mixing and curing component A and component B at a mass ratio of 12:1, an asphalt-based material that can quickly repair cracks in asphalt pavement is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average volume particle size | aaaaa | aaaaa |

| Volume particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap