Preparation method of tobacco microcapsule spearmint oil

A technology of spearmint oil and microcapsules, which is applied in the field of cigarettes, can solve problems such as no public reports, and achieve the effects of simple production process, improved taste and reduced irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

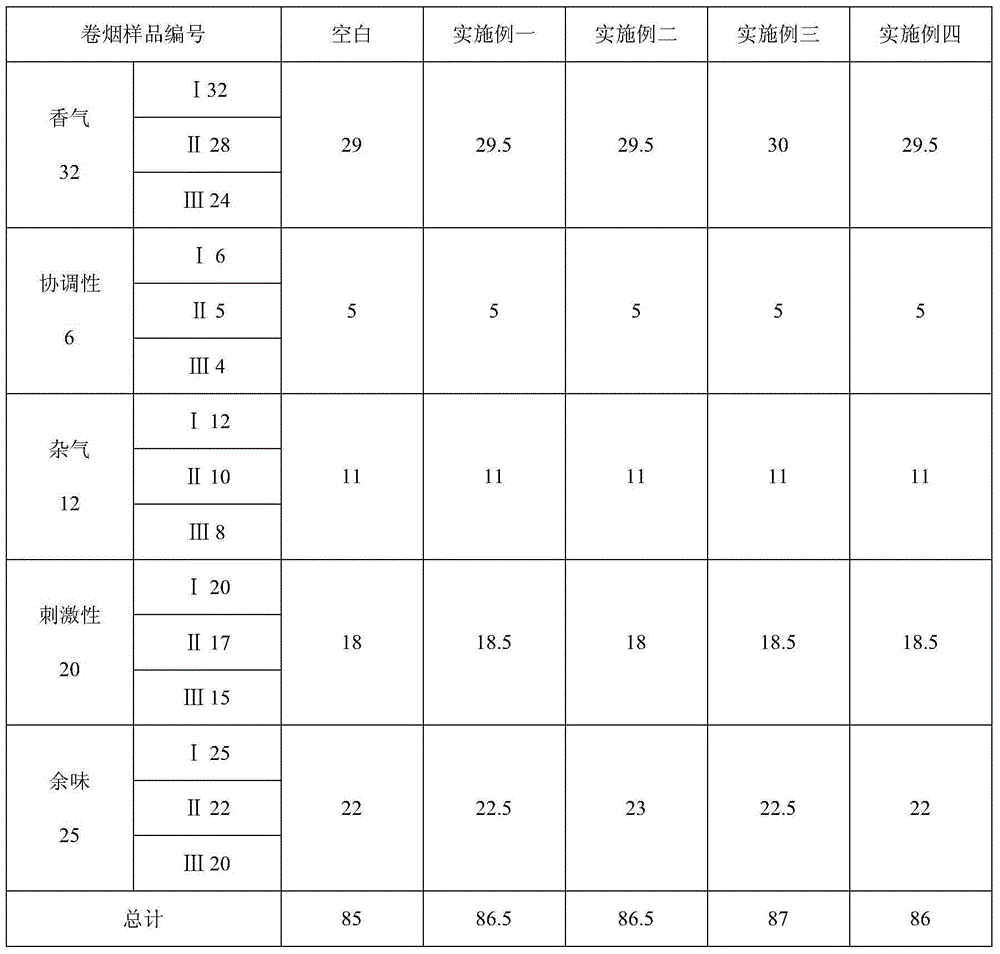

Examples

Embodiment 1

[0014] a. Preparation of microcapsule emulsion: Weigh 10g each of gelatin and gum arabic as the wall material according to the ratio of 1:1, add 100g of distilled water which is 5 times the mass of the wall material, fully dissolve and mix evenly in a water bath at 40°C , to obtain a wall material solution; add spearmint oil of 1 / 10 of the wall material quality, that is, 2g, as a core material, and use a high-speed disperser to continuously emulsify for 2min under the condition of 400r / min to form a uniform emulsion;

[0015] b. Microcapsule complex coacervation reaction: add 200g distilled water to the emulsion in step a and dilute it into an emulsion in which the wall material accounts for 6% of the total mass, stir at 40°C and add 10% acetic acid solution dropwise to adjust the pH value To 3.8, make the wall material condense and keep warm for 10 minutes, so that the condensed phase gathers around the core material and forms a package;

[0016] c. microcapsule solidificatio...

Embodiment 2

[0019] a. Preparation of microcapsule emulsion: Weigh 10g of gelatin and 20g of gum arabic as the wall material according to the ratio of 1:2, add 90g of distilled water which is 3 times the mass of the wall material, fully dissolve and mix in a water bath at 45°C Evenly, add spearmint oil of 1 / 15 of the mass of the wall material, that is, 2g, as the core material, and use a high-speed disperser to continuously emulsify for 3 minutes under the condition of 200r / min to obtain a uniform emulsion;

[0020] b. Microcapsule complex coacervation reaction: add 310g distilled water to the emulsion in step a and dilute it into an emulsion in which the wall material accounts for 7% of the total mass, stir at 45°C and add dropwise 10% acetic acid solution to adjust When the pH value reaches 4.0, the wall material is condensed, and the temperature is kept for 15 minutes, so that the condensed phase gathers around the core material and forms a coating; c. Microcapsule curing reaction: cool ...

Embodiment 3

[0023] a. Preparation of microcapsule emulsion: Weigh 10g of gelatin and 30g of gum arabic as the wall material according to the ratio of 1:3, add 160g of distilled water which is 4 times the mass of the wall material, fully dissolve and mix in a water bath at 50°C Evenly, add spearmint oil of 1 / 8 of the mass of the wall material, that is, 5g, as the core material, and use a high-speed disperser to continuously emulsify for 3 minutes under the condition of 1000r / min to obtain a uniform emulsion;

[0024] b. Microcapsule complex coacervation reaction: add 600g distilled water to the emulsion in step a and dilute it into an emulsion in which the wall material accounts for 5% of the total mass, stir at 50°C and add dropwise 10% acetic acid solution to adjust When the pH value reaches 3.0, the wall material will be condensed, and the temperature is kept for 5 minutes, so that the condensed phase gathers around the core material and forms a coating;

[0025] c. Microcapsule curing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com