Preparation method for high-hardness hammer head for radial precision forging machine

A high-hardness, precision forging machine technology, applied in coatings, metal material coating processes, etc., can solve the problems of difficult to meet the production requirements of high-performance alloys, easy to produce deformation, fracture and scrap, etc., to achieve dense organization and lower working temperature. , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

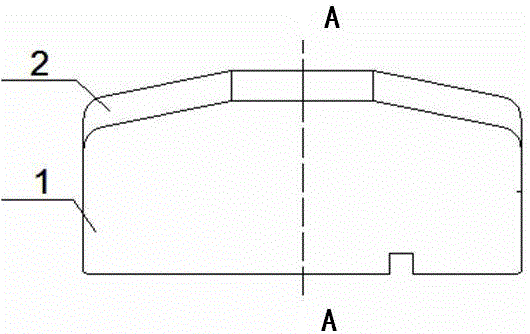

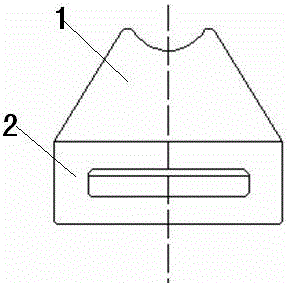

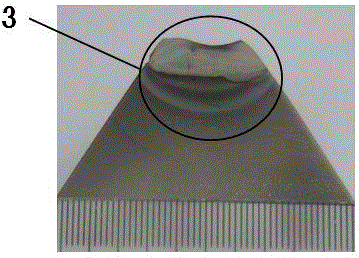

Image

Examples

Embodiment 1

[0030] A method for preparing a high-hardness hammerhead for a radial precision forging machine, the specific steps are as follows:

[0031] 1) Matrix forging: the matrix material is 4Cr5MoSiV1 hot forging abrasive steel, its chemical composition: C0.32%, Si0.85%, Mn≤0.40%, Cr4.5%, Mo1.0%, V0.8%, the rest Fe, forging process of hot work die steel: forging temperature is 750°C, forging ratio 2.5; forging annealing process is: 860°C, heat preservation 2h, furnace cooling to 540°C, air cooling;

[0032] 2) Heat treatment of matrix; heat treatment process of 4Cr5MoSiV1 hot work die steel forgings: oil quenching at 1000°C, tempering at 500°C;

[0033] 3) Substrate surface treatment: Grinding and shot blasting the working surface of the substrate; the treatment process uses 40-80 mesh white corundum (HRC70-90), and the treatment time is 1-2 hours;

[0034] 4) Laser cladding on the working surface of the substrate; a. Selection of cladding materials; the material for laser cladding ...

Embodiment 2

[0037] A method for preparing a high-hardness hammerhead for a radial precision forging machine, the specific steps are as follows:

[0038] 1) Matrix forging; the matrix material is 4Cr5MoSiV1 hot forging abrasive steel, its chemical composition: C0.35%, Si0.90%, Mn≤0.40%, Cr4.5%, Mo1.2%, V0.9%, the rest It is Fe; forging process of hot work die steel: forging temperature is 750°C, forging ratio is 2.7; forging annealing process is: 860°C, heat preservation for 2h, furnace cooling to 540°C, air cooling;

[0039] 2) Heat treatment of matrix; heat treatment process of 4Cr5MoSiV1 hot work die steel forgings: oil quenching at 1000°C, tempering at 500°C;

[0040] 3) Substrate surface treatment: Grinding and shot blasting the working surface of the substrate; the treatment process uses 40-80 mesh white corundum (HRC70-90), and the treatment time is 1-2 hours;

[0041] 4) Laser cladding on the working surface of the substrate; a. Selection of cladding materials; the material for la...

Embodiment 3

[0044] A method for preparing a high-hardness hammer head for a radial precision forging machine, the specific steps are as follows:

[0045]1) Matrix forging; the matrix material is 4Cr5MoSiV1 hot forging abrasive steel, its chemical composition: C0.40%, Si1.0%, Mn≤0.40%, Cr4.8%, Mo1.3%, V1.0%, the rest It is Fe; the forging process of hot work die steel: the forging temperature is 800 °C, the forging ratio is 3.0; the annealing process of the forging is: 890 °C, heat preservation for 4 hours, furnace cooling to 540 °C, air cooling;

[0046] 2) Matrix heat treatment; heat treatment process of 4Cr5MoSiV1 hot work die steel forgings: oil quenching at 1050℃, tempering at 550℃;

[0047] 3) Surface treatment of the substrate; grinding and shot peening the working surface of the substrate; 40~80 mesh white corundum (HRC70~90) is used for the treatment process, and the treatment time is 1~2 hours;

[0048] 4) Laser cladding on the working surface of the base body; a. Selection of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com