Method of producing uniform, fine polymer beads by vibration jetting

一种聚合物珠、聚合单体的技术,应用在使原料颗粒化的方法、抖动/振荡/振动混合机、化学仪器和方法等方向,能够解决板喷射法整体生产率低、能量损失大、难以实施商业操作等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Preparation of Homogeneous Gel Polymer Beads (Volume Average Diameter 166 μm)

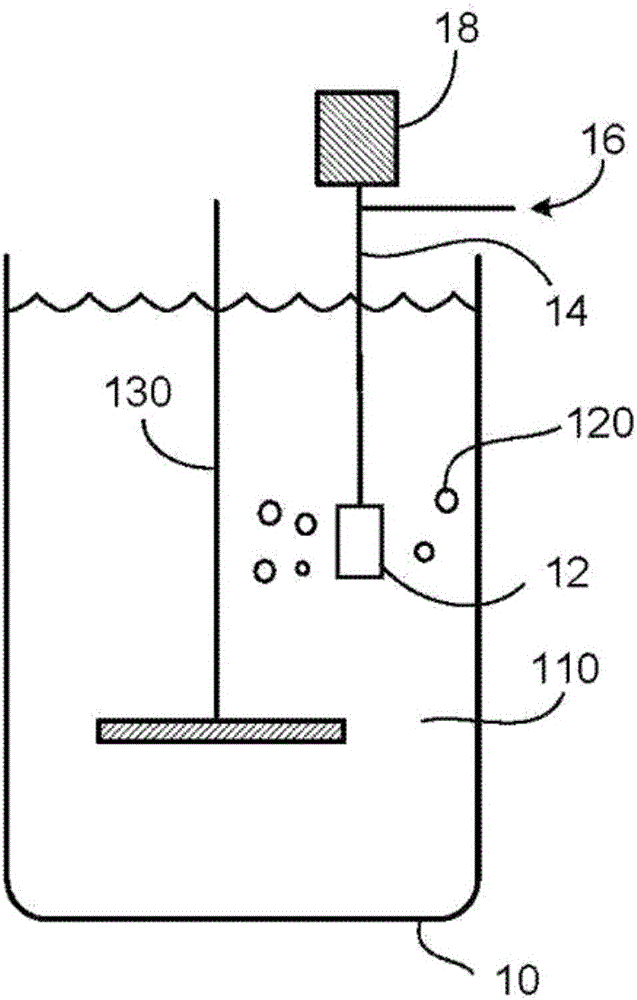

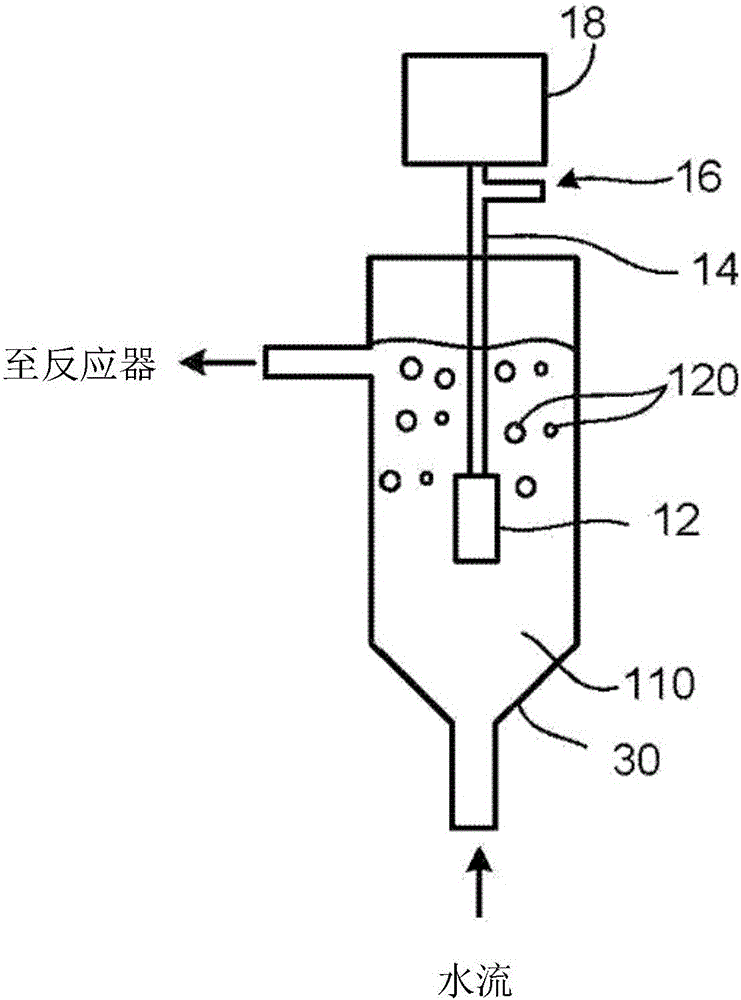

[0048] Polymeric beads of uniform particle size are used as image 3 A device of the configuration shown is manufactured. An aqueous phase with a viscosity of 1 to 1.2 centipoise comprising distilled water (4 kg) and polyvinyl alcohol (20 g) was prepared at neutral pH. The aqueous solution was fed to the collection column 30 at a rate of 16 l / hour. A monomer phase was prepared comprising styrene (2.25 kg), divinylbenzene (80%; 0.25 g) and tert-butyl peroxy-2-ethylhexanoate (5 g). The monomer phase was prepared under agitation in a monomer mix tank. The monomer phase was then fed to the monomer reservoir feed line 16 at a flow rate of 12.6 1 / hour. The membrane was then vibrated at 60 Hz and a peak-to-peak amplitude of 1.82 mm.

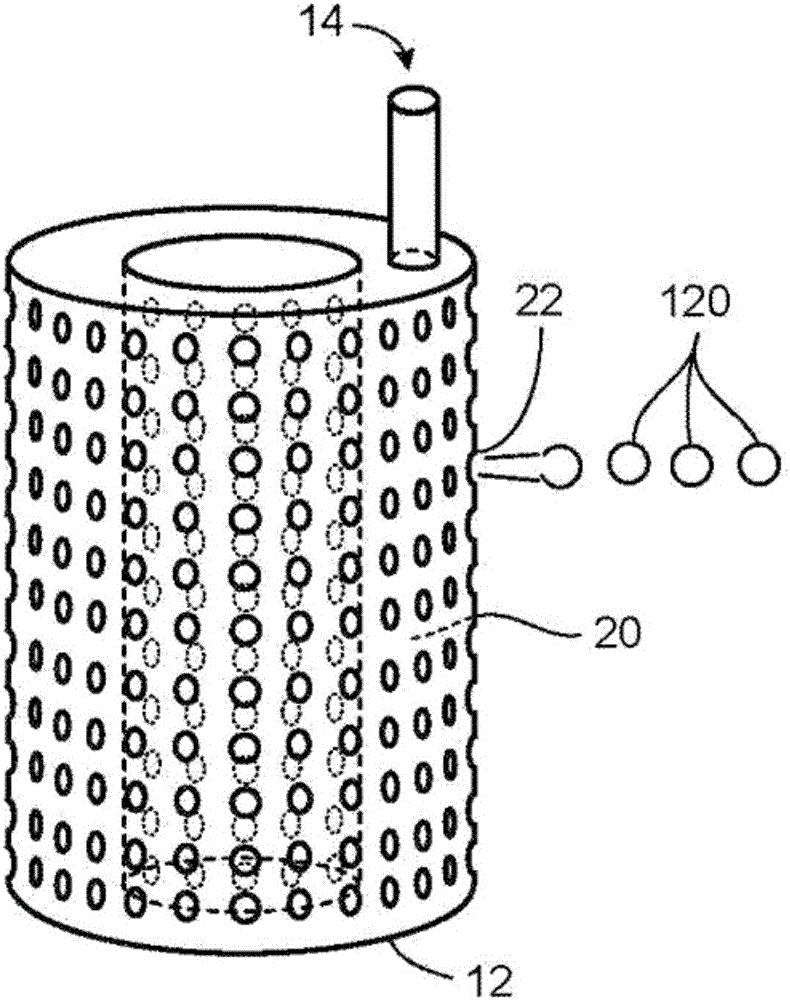

[0049] The membrane used in this example was a 4×4 cm (L / d) nickel-based membrane (pure nickel) including thousands of 40 μm through-holes connecting the suspend...

Embodiment 2

[0059] Preparation of uniform macroporous polymer beads (volume mean diameter 180 μm) of embodiment 2

[0060] Polymeric beads of uniform particle size are used as image 3 A device of the configuration shown is manufactured. An aqueous phase with a viscosity of 1 to 1.5 centipoise comprising distilled water (4 kg) and polyvinyl alcohol (20 g) was prepared at neutral pH. The aqueous solution was added to the disperser unit 30 and stirred to mix at room temperature. A monomer phase was prepared comprising styrene (1.8 kg), divinylbenzene (63%; 122.1 g), isooctane (1.9 kg) and tert-butyl peroxy-2-ethylhexanoate (56 g). The monomer phase was prepared under agitation in a monomer mix tank (not shown). The monomer phase was then fed to the membrane 12 at a flow rate of 13.2 l / hour. The membrane 12 was then vibrated at 48 Hz and an amplitude of 2.76 mm to provide 180 μm droplets, 90% of which were in the range of 136 to 202 μm. A droplet formation productivity in the range of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com