Preparation method of 2-substituted-1,3-dithiane derivative

A technology of dithiane and derivatives, applied in the field of substituting 1, which can solve problems such as complex preparation methods, limited applications, and toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

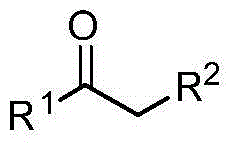

Method used

Image

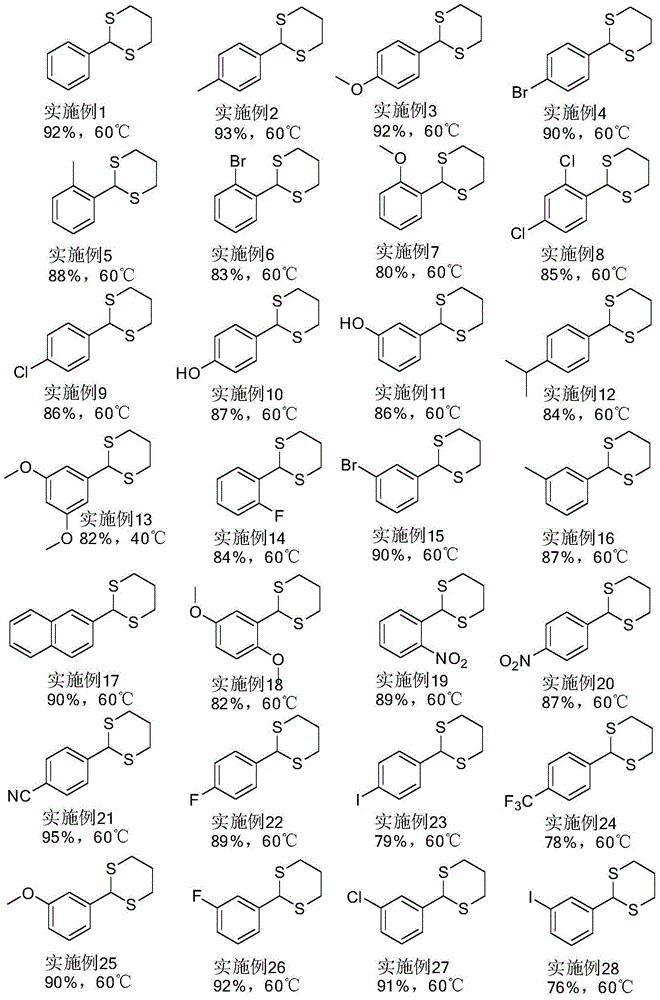

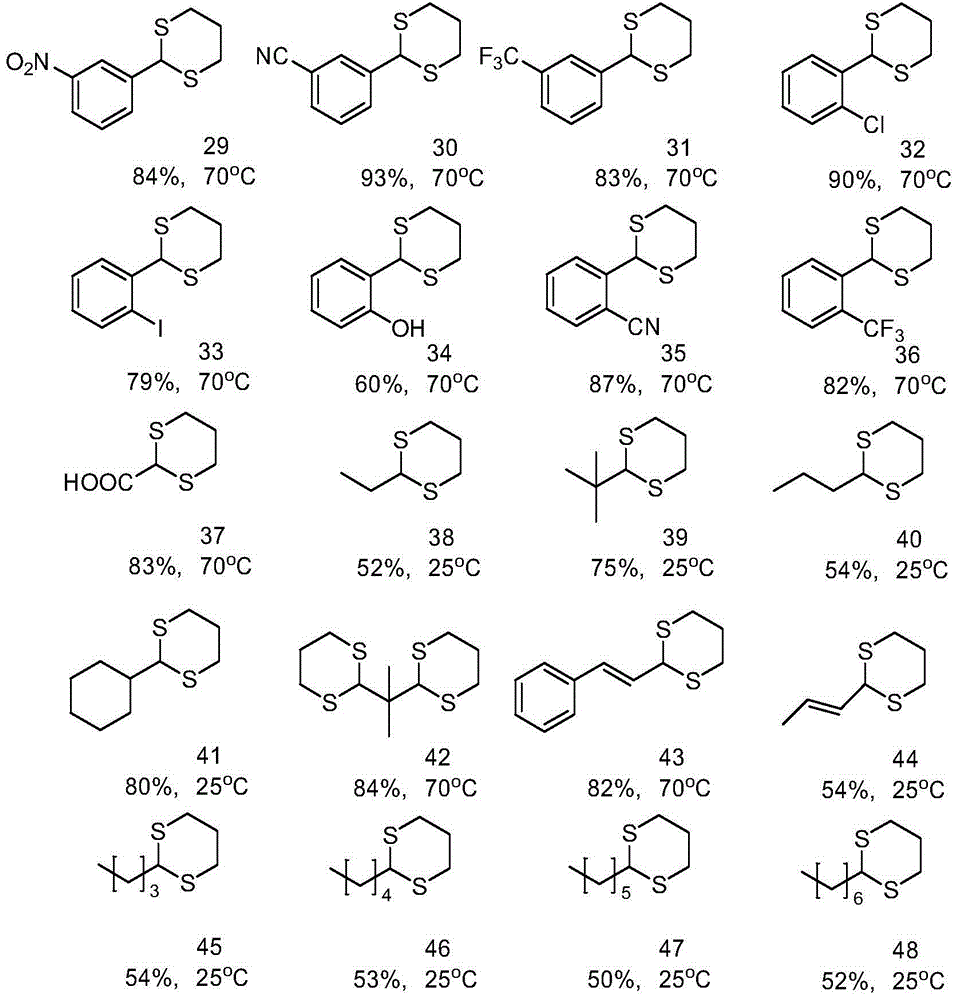

Examples

Embodiment 1

[0019] Example 1 In a 10ml round bottom flask, add 1,3-dithiane (0.250mmol), NCS (0.300mmol), add 2ml of DCE to dissolve and react at -10°C for 0.5-1h. After TLC monitoring, benzaldehyde (0.250 mmol) and ferric chloride (0.025 mmol) were added after the reaction was complete, and the reaction was continued for 12 hours. After TLC detection, the solvent was evaporated after the reaction was complete, and the product was obtained by column chromatography.

Embodiment 3

[0020] Example 3 In a 10 ml round bottom flask, add 1,3-dithiane (0.250 mmol), NCS (0.300 mmol), add 2 ml of DCE to dissolve and react at -10°C for 0.5 to 1 h. After TLC monitoring, after the reaction was complete, p-methoxybenzaldehyde (0.250 mmol) and boron trifluoride ether (0.025 mmol) were added, and the reaction was continued for 4 h. After TLC detection, the solvent was evaporated after the reaction was complete, and the product was obtained by column chromatography.

[0021] Implementation 40 In a 10 ml round bottom flask, add 1,3-dithiane (0.250 mmol), NCS (0.300 mmol), add 2 ml of DCE to dissolve and react at -10°C for 0.5 to 1 h. After TLC monitoring, n-butyraldehyde (0.250 mmol) and ferric chloride (0.025 mmol) were added after the reaction was complete, and the reaction was continued for 8 h. After TLC detection, the solvent was evaporated after the reaction was complete, and the product was obtained by column chromatography.

Embodiment 44

[0022] Example 44 In a 10 ml round bottom flask, 1,3-dithiane (0.250 mmol) and NCS (0.300 mmol) were added, 2 ml of DCE was added to dissolve, and reacted at -10° C. for 0.5 to 1 h. After TLC monitoring, after the reaction was complete, crotonaldehyde (0.250 mmol) and ferric chloride (0.025 mmol) were added, and the reaction was continued for 8 h. After TLC detection, the solvent was evaporated after the reaction was complete, and the product was obtained by column chromatography.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com