Method for preparing conductive organosilicone pouring sealant

A technology of silicone potting glue and conductive type, which is applied in the direction of conductive adhesives, adhesives, non-polymer adhesive additives, etc., can solve the problems of ineffective removal of static electricity, lack of electrical conductivity, etc., and achieve lower resistivity , Improve electrical conductivity, remove static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

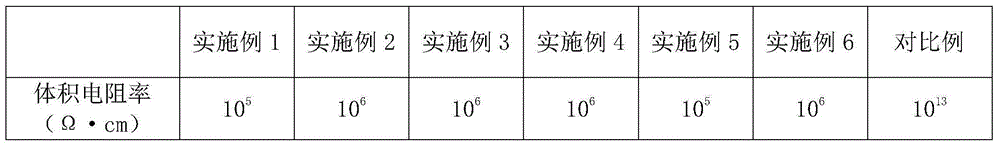

Examples

Embodiment 1

[0025] A preparation method of conductive silicone potting glue, the steps are as follows:

[0026] (1) Dissolve SDBS in acetone and disperse evenly, add acetic acid to adjust the pH value to 4 to obtain SDBS solution, add aluminum-doped zinc oxide to deionized water and stir evenly, then add SDBS solution and stir at 80 ° C for 2.5 hours, move to Ultrasonic treatment for 15 minutes in an ultrasonic machine with an ultrasonic power of 120W, vacuum filtration after discharging, washing with deionized water for 10 minutes, drying in a vacuum drying oven at 90°C to constant weight, and obtaining modified aluminum-doped Zinc oxide powder is ready for use, the weight ratio of SDBS and aluminum-doped zinc oxide is 1:8;

[0027] (2) 100 parts by weight of hydroxyl-terminated polydimethylsiloxane, 14 parts by weight of polyparaphenylene, 20 parts by weight of kaolin, 0.6 parts by weight of KH560 and 28 parts by weight of the modified product obtained in step (1) Add aluminum-doped zi...

Embodiment 2

[0032] A preparation method of conductive silicone potting glue, the steps are as follows:

[0033] (1) Dissolve SDBS in acetone and disperse evenly, add acetic acid to adjust the pH value to 4 to obtain SDBS solution, add aluminum-doped zinc oxide to deionized water and stir evenly, then add SDBS solution and stir at 80 ° C for 2.5 hours, move to Ultrasonic treatment for 15 minutes in an ultrasonic machine with an ultrasonic power of 120W, vacuum filtration after discharging, washing with deionized water for 10 minutes, drying in a vacuum drying oven at 90°C to constant weight, and obtaining modified aluminum-doped Zinc oxide powder is ready for use, the weight ratio of SDBS and aluminum-doped zinc oxide is 1:8;

[0034] (2) 100 parts by weight of hydroxyl-terminated polydimethylsiloxane, 15 parts by weight of polyparaphenylene, 22 parts by weight of quartz powder, 0.5 parts by weight of KH560 and 20 parts by weight of the step (1) obtained The modified aluminum-doped zinc o...

Embodiment 3

[0039] A preparation method of conductive silicone potting glue, the steps are as follows:

[0040] (1) Dissolve SDBS in acetone and disperse evenly, add acetic acid to adjust the pH value to 4 to obtain SDBS solution, add aluminum-doped zinc oxide to deionized water and stir evenly, then add SDBS solution and stir at 80 ° C for 2.5 hours, move to Ultrasonic treatment for 15 minutes in an ultrasonic machine with an ultrasonic power of 120W, vacuum filtration after discharging, washing with deionized water for 10 minutes, drying in a vacuum drying oven at 90°C to constant weight, and obtaining modified aluminum-doped Zinc oxide powder is ready for use, the weight ratio of SDBS and aluminum-doped zinc oxide is 1:8;

[0041] (2) 100 parts by weight of hydroxyl-terminated polydimethylsiloxane, 10 parts by weight of polyparaphenylene, 24 parts by weight of kaolin, 0.6 parts by weight of KH560 and 25 parts by weight of the modified product obtained in step (1) Add aluminum-doped zi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com