Fe-based amorphous alloy with high saturation magnetic induction intensity and strong amorphous forming ability

A technology of iron-based amorphous alloy and magnetic induction intensity, which is applied in the direction of magnetic materials, manufacturing tools, magnetic objects, etc., can solve the problems of reducing the saturation magnetic induction intensity of the alloy, increasing the complexity of the process, and lacking, etc., to achieve strong amorphous formation ability, Easy to close-packed structure, fast stress release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-22

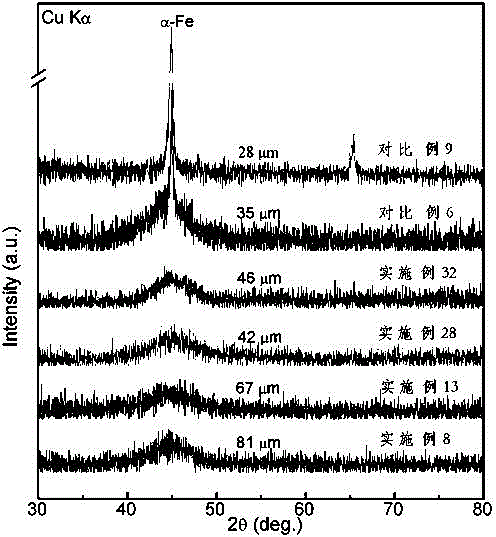

[0062] Using common industrial raw materials, the smelting component is Fe 83 C 1 m f Si b B c P d Alloys, Examples 1-22. M element is the impurity in the raw material when Fe, Si, B, P and C elements are added, regardless of the influence of its type and content f, only its influence on the performance of the alloy is considered as a whole.

[0063] The molten alloy is sprayed onto a 30m / s rotating copper roller through a nozzle of a certain shape to prepare an alloy strip with a width of about 1mm and a thickness of about 25μm. The strip is determined to be amorphous by XRD. The strips were used to test the magnetic properties of the samples after heat treatment and the toughness of the strips before and after heat treatment.

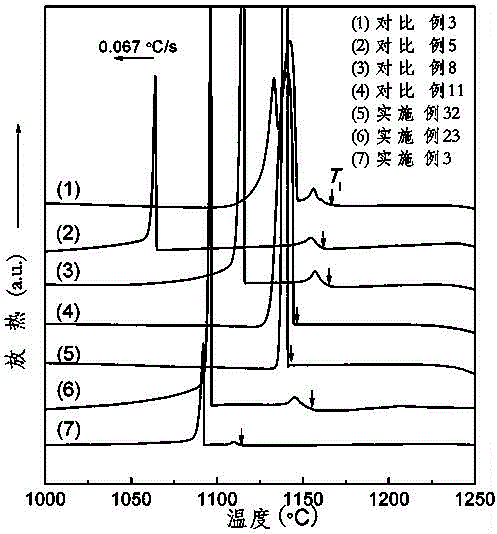

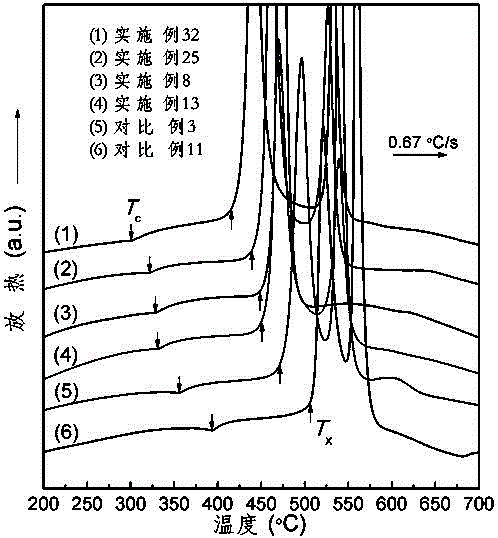

[0064] Obtain the thermodynamic parameters (comprising the Curie temperature T of the amorphous alloy) of the above-mentioned prepared amorphous alloy with differential scanning calorimetry c , initial crystallization temperature T x1 and liqu...

Embodiment 23~28

[0079] With common industrial raw materials, the smelting components are (Fe 83 Si 2.5 B 10.5 P 3 ) (100-x) / 99 C x Alloys, Examples 23-28. M element is the impurity in the raw material when Fe, Si, B, P and C elements are added, regardless of the influence of its type and content f, only its influence on the performance of the alloy is considered as a whole.

[0080] Use a nozzle of a certain shape to spray onto a 30m / s rotating copper roller to prepare an alloy strip with a width of about 1mm and a thickness of about 25μm. XRD is used to confirm that the strip is an amorphous structure. The magnetic properties of the samples after heat treatment and the toughness of the strips before and after heat treatment were tested with 25 μm thick amorphous ribbons.

[0081] Obtain the thermodynamic parameters (including the Curie temperature T of the amorphous) of the bulk amorphous alloy prepared above by differential scanning calorimetry c , initial crystallization temperature...

Embodiment 29-32

[0088] Using common industrial raw materials, the smelting component is Fe x (Si 2.5 B 10.5 P 3 C 1 ) (100-x) / 17 Alloys, Examples 29-32. M element is the impurity in the raw material when Fe, Si, B, P and C elements are added, regardless of the influence of its type and content f, only its influence on the performance of the alloy is considered as a whole.

[0089] Use a nozzle of a certain shape to spray onto a 30m / s rotating copper roller to prepare an alloy strip with a width of about 1mm and a thickness of about 25μm. XRD is used to confirm that the strip is an amorphous structure. The magnetic properties of the samples after heat treatment and the toughness of the strips before and after heat treatment were tested with 25 μm thick amorphous ribbons.

[0090] Obtain the thermodynamic parameters (including the Curie temperature T of the amorphous) of the bulk amorphous alloy prepared above by differential scanning calorimetry c , initial crystallization temperature T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com