Electrolyte solution compatible with lithium-ion battery anode material lithium titanate

A technology for lithium ion batteries and negative electrode materials, applied in the field of electrolytes, can solve problems such as unproven use and potential safety hazards, and achieve the effects of reducing redox capacity, preventing reduction and decomposition, and having good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

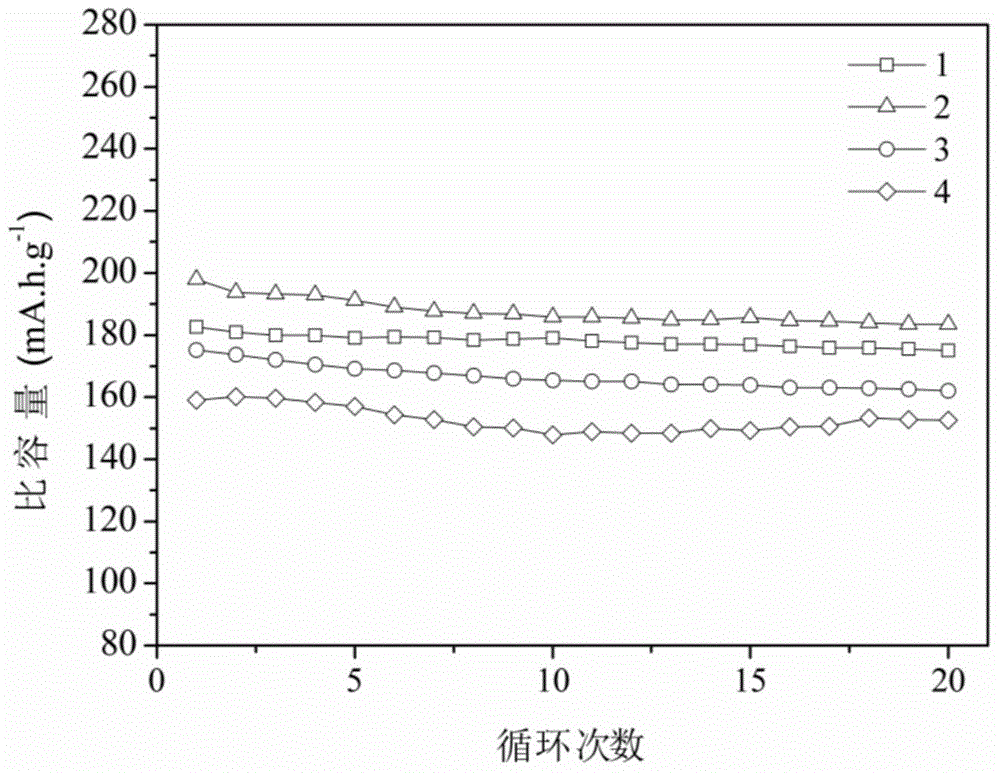

[0024] An electrolyte compatible with lithium titanate, the negative electrode material of lithium-ion batteries. The electrolyte consists of solvents, electrolytes and additives, wherein the solvent is composed of ethyl methyl carbonate, propylene carbonate and ethylene carbonate, and the electrolyte is LiPF 6 , the additive is LiBOB, the mass ratio of methyl ethyl carbonate (MEC), propylene carbonate (PC) and ethylene carbonate (EC) in the solvent is 2:3:5, and the electrolyte LiPF 6 The concentration in the solvent is 1.1 mol / L, and the mass of the additive LiBOB is 2.5% of the mass of the solvent.

Embodiment 2

[0026] An electrolyte compatible with lithium titanate, the negative electrode material of lithium-ion batteries. The electrolyte consists of solvents, electrolytes and additives, wherein the solvent is composed of ethyl methyl carbonate, propylene carbonate and ethylene carbonate, and the electrolyte is LiPF 6 , the additive is LiBOB, the mass ratio of methyl ethyl carbonate (MEC), propylene carbonate (PC) and ethylene carbonate (EC) in the solvent is 1:2:4, and the electrolyte LiPF 6 The concentration in the solvent is 0.8 mol / L, and the mass of the additive LiBOB is 1.0% of the mass of the solvent.

Embodiment 3

[0028]An electrolyte compatible with lithium titanate, the negative electrode material of lithium-ion batteries. The electrolyte is composed of a solvent, an electrolyte and an additive, wherein the solvent is composed of ethyl methyl carbonate, propylene carbonate and ethylene carbonate, and the electrolyte is LiPF 6 , the additive is LiBOB, the mass ratio of methyl ethyl carbonate (MEC), propylene carbonate (PC) and ethylene carbonate (EC) in the solvent is 3:4:6, and the electrolyte LiPF 6 The concentration in the solvent is 1.0 mol / L, and the mass of the additive LiBOB is 3.0% of the mass of the solvent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com