Preparation method for inorganic powder material and application

A technology of inorganic powder materials and precursors, applied in the direction of inorganic chemistry, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of high cost, and the cost of activated carbon itself and recovery cost are also limited, and the environmental requirements of aqueous solution High, large amount of chemical reagents and other problems, to achieve good industrial application prospects, clean and pollution-free preparation process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

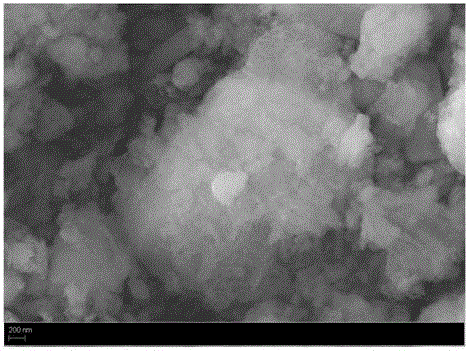

[0023] In the container, 3g CaCO 3 , 0.5gSiO 2 , 0.12gFe 2 o 3 and 0.16gAl 2 o 3 After grinding for 10 minutes, the mixture is obtained; the obtained mixture is placed in a muffle furnace and heated to 1000 ° C for 10 minutes, and after cooling, the roasted product is washed 3 times with tap water, and the washed roasted product is naturally dried and ground for 10 minutes to obtain the present invention. Described inorganic powder material, its scanning electron microscope picture is as follows figure 1 shown.

Embodiment 2

[0025] In the container, put 2.5gCaO, 1gSiO 2 and 0.3gAl 2 o 3 After grinding for 10 minutes, the mixture was obtained; the obtained mixture was placed in a muffle furnace and heated to 1000°C for 10 minutes, and the roasted product was washed once with tap water after cooling, and the washed roasted product was naturally dried and ground for 10 minutes to obtain the present invention. The inorganic powder material.

Embodiment 3

[0027] In the container, 3g CaCO 3 , 1.2gSiO2 2 , 0.2gFe 3 o 4 and 0.3gAl 2 o 3 After grinding for 10 minutes, the mixture was obtained; the obtained mixture was placed in a muffle furnace and heated to 900°C for 10 minutes, and the roasted product was washed once with tap water after cooling, and the washed roasted product was naturally dried and ground for 10 minutes to obtain the present invention. The inorganic powder material.

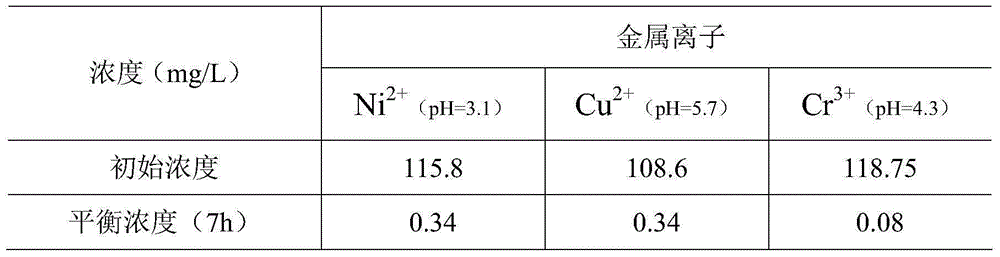

[0028] Treat the waste liquid containing nickel ion, copper ion, chromium (III) ion with the inorganic powder material obtained in embodiment 3, illustrate the inorganic powder material obtained by the present invention with the removal effect of copper ion and nickel ion processing power. Among them, the ion waste liquid comes from the electroplating factory.

[0029] The inorganic powder material obtained in Example 3 of the present invention treats nickel, copper, chromium (III) ion waste liquid as follows: add alkali in the ion waste li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com