A surface treatment process for container welds

A surface treatment and container technology, applied in the field of laser treatment, can solve the problems of affecting environmental sanitation, affecting aesthetics, harsh working environment, etc., and achieving the effects of less environmental pollution, easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

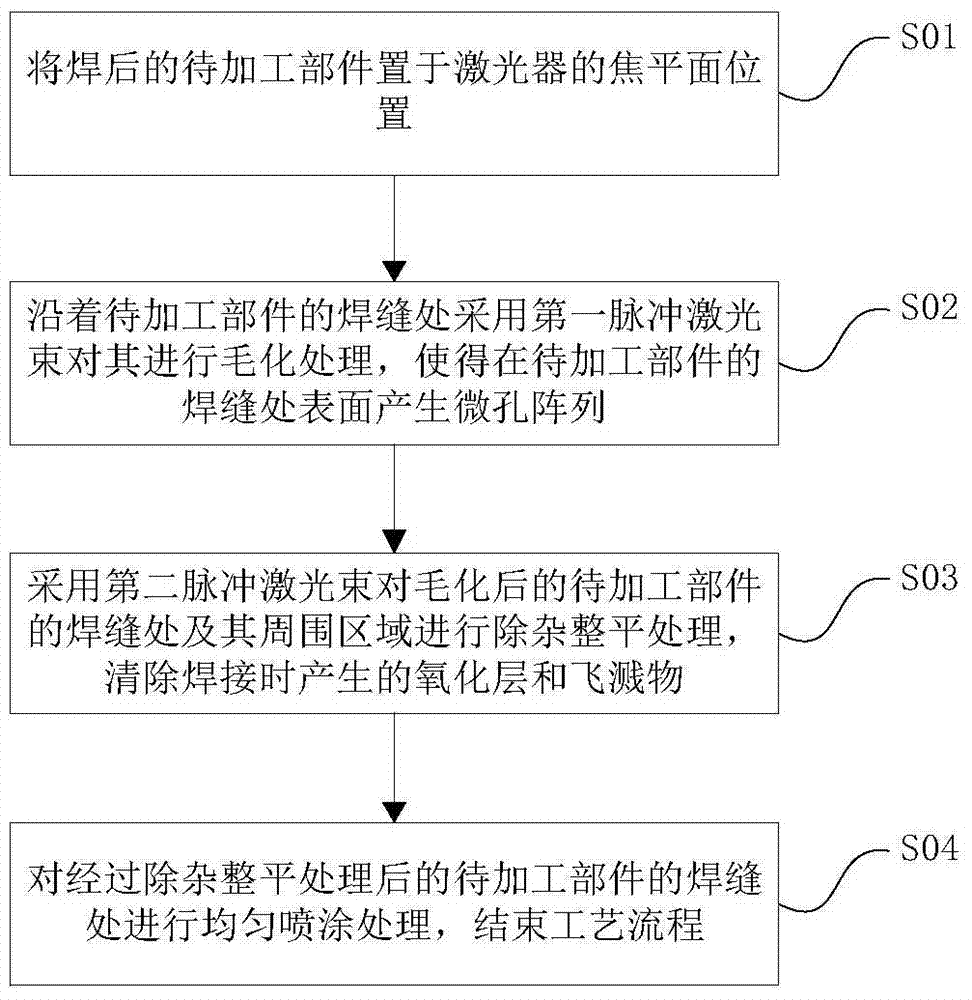

[0030] Such as figure 1 As shown, a surface treatment process for container welds includes the following steps:

[0031] Step S01: placing the welded part to be processed on the focal plane of the laser;

[0032] Step S02: Using the first pulsed laser beam to roughen the welding seam of the part to be processed, so that a microhole array is generated on the surface of the welding seam of the part to be processed;

[0033] Step S03: Use the second pulsed laser beam to perform impurity removal and leveling treatment on the weld seam of the roughened parts to be processed and its surrounding area, remove the oxide layer and spatter generated during welding, and reach the weld seam of the parts to be processed smooth ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com