Method for improving transparency of acid prepared from secondary baking flue gas of cyanidation tailings

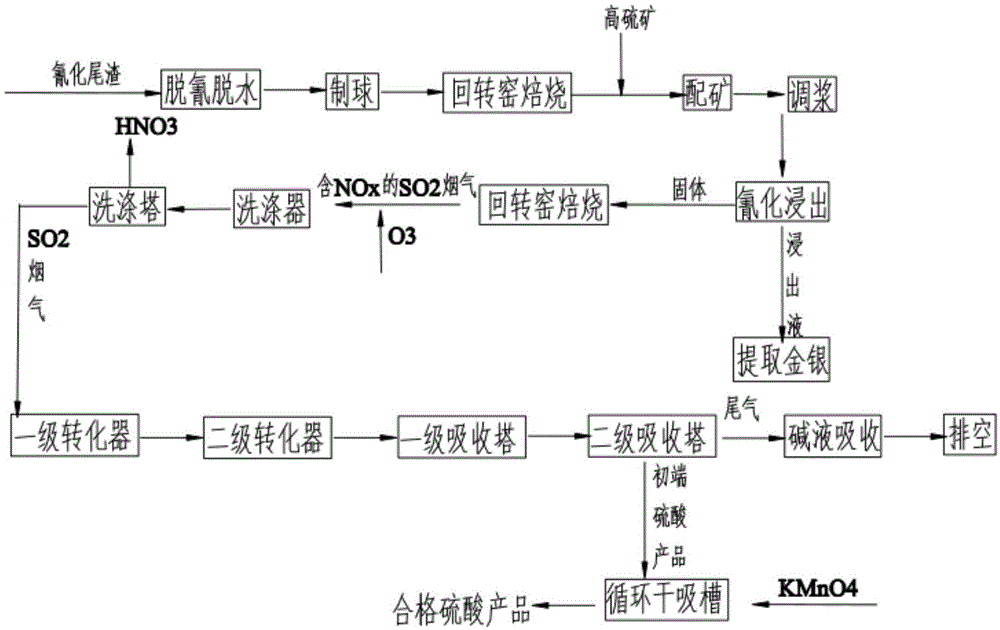

A technology for producing acid from cyanide tailings and flue gas is applied in chemical instruments and methods, improvement of process efficiency, nitrogen oxides/oxygen acids, etc., to achieve the effects of high utilization rate of raw materials, simple operation steps, and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

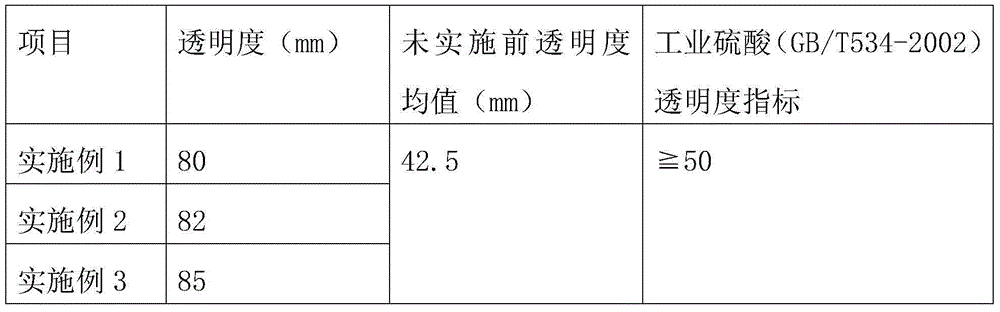

Embodiment 1

[0025] A method for improving the transparency of acid production from secondary roasting flue gas of cyanidation tailings, comprising the steps of:

[0026] 1) Decyanation of cyanide tailings: put the cyanide tailings produced by the second-stage roasting cyanation process containing 380mg / t of cyanide in an oven at 40°C for 1 hour to reduce cyanide and moisture, and the cyanide root is initially reduced to 310mg / t , the moisture content is reduced to 19wt%, and it is pressed into pellets with a diameter of 5mm by using a hydraulic pellet machine, and placed in a rotary kiln at 260°C for 5 hours to remove cyanide, and the cyanide content of the cyanide tailings after roasting is further reduced to 0.5 mg / t, the moisture content is 8wt%, and the water vapor containing cyanide is collected in the dilute acid reaction tank;

[0027] 2) Desulfurization by ore blending: after decyanation, the pellets and high-sulfur ore with a sulfur content of 38wt% are blended according to a mas...

Embodiment 2

[0035] A method for improving the transparency of acid production from secondary roasting flue gas of cyanidation tailings, comprising the steps of:

[0036] 1) Decyanation of cyanide tailings: The cyanide tailings produced by the second-stage roasting cyanation process containing cyanide 406mg / t were placed in the air at 30°C for 3 hours to reduce cyanide and moisture, and the cyanide was initially reduced to 345mg / t t, moisture content is reduced to 21wt%, utilizes the hydraulic pressure ball machine to press into the pellet that diameter is 8mm, puts in the rotary kiln of 280 ℃ and roasts 3 hours decyanation, the cyanide radical content of the cyanide tailings after roasting is further reduced to 1.0mg / t, moisture content 9.5wt%, the water vapor containing cyanide is collected in dilute acid reaction pool;

[0037] 2) Desulfurization by ore blending: after decyanation, the pellets and high-sulfur ore with a sulfur content of 44wt% are blended according to a mass ratio of 1:...

Embodiment 3

[0045] A method for improving the transparency of acid production from secondary roasting flue gas of cyanidation tailings, comprising the steps of:

[0046] 1) Decyanation of cyanide tailings: The cyanide tailings produced by the second-stage roasting cyanation process and containing 430 mg / t of cyanide are placed in the air at 20 ° C for 8 hours to reduce cyanide and moisture, and the cyanide is initially reduced to 380 mg / t. t, moisture content is reduced to 23wt%, utilizes the hydraulic pressure ball machine to press into the pellet that diameter is 10mm, puts in the rotary kiln of 300 ℃ and roasts 2 hours decyanation, the cyanide radical content of the cyanide tailings after roasting is further reduced to 1.5mg / t, moisture content 11wt%, the water vapor containing cyanide is collected in dilute acid reaction pool;

[0047] 2) Desulfurization by ore blending: after decyanation, the pellets and high-sulfur ore with a sulfur content of 49wt% are blended according to the mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparency | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com