Phyllosilicate/natural latex composite adhesive film and preparation method thereof

A technology of layered silicate and natural rubber latex, which is applied in the field of preparation of natural rubber latex film, to achieve easy industrialization, enhanced interface performance, obvious effects of tear strength and modulus stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

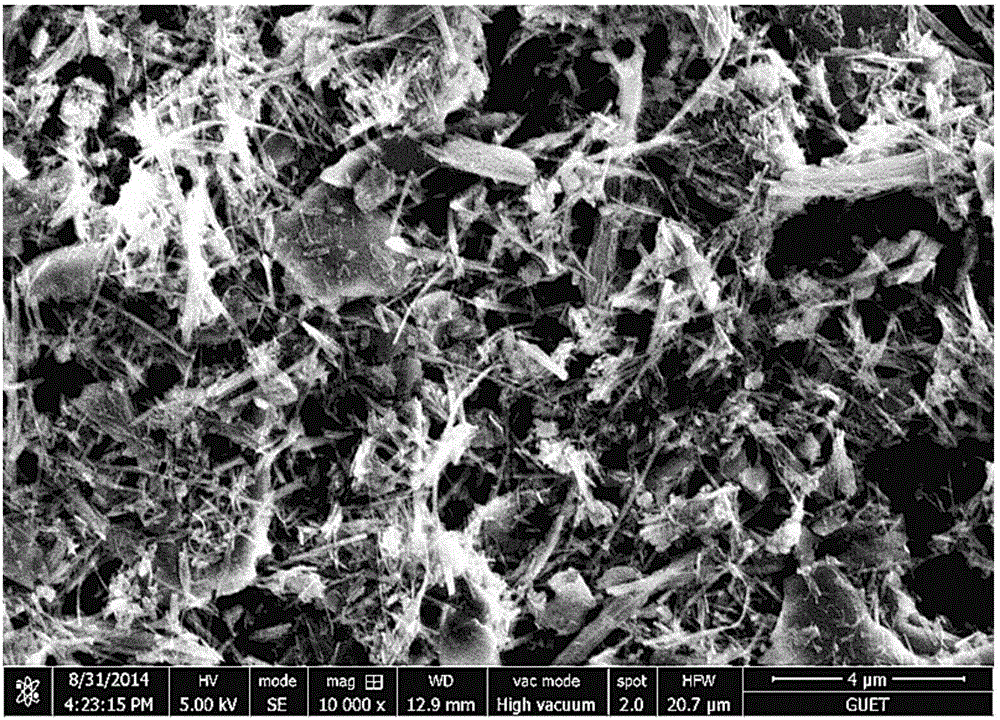

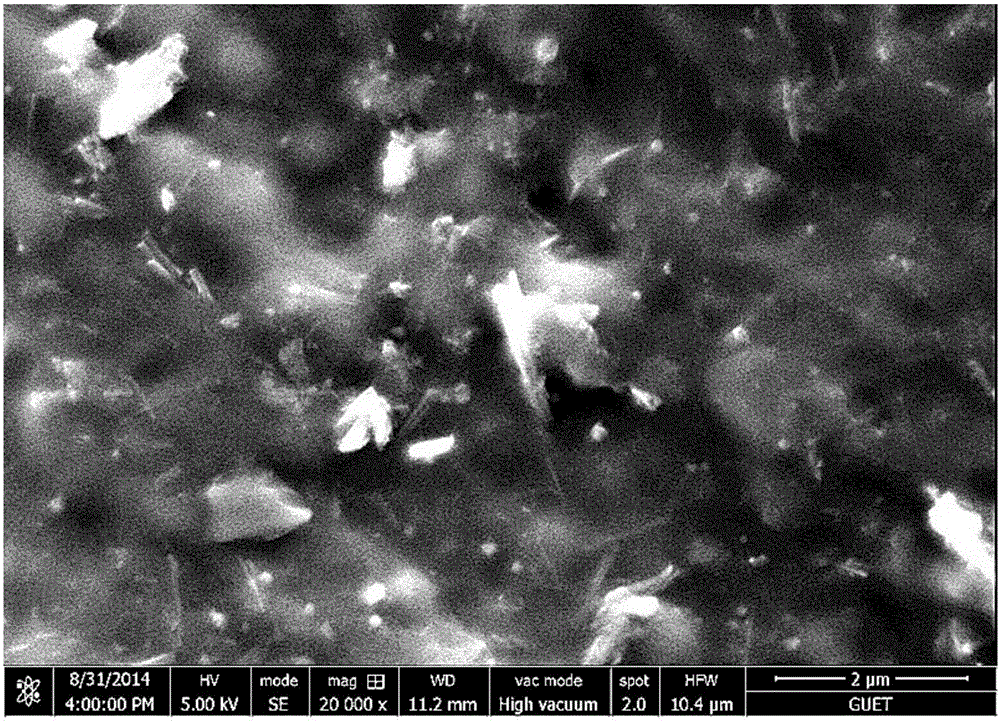

[0040] 1) Weigh 20 grams of raw sepiolite powder (100-200 mesh) into a beaker, add 400 ml of 1 mol / L hydrochloric acid solution, stir for 15 minutes, and ultrasonically disperse at 70°C for 2 hours. After standing for 12 hours, take the suspension, wash it repeatedly with deionized water, control the density of sepiolite to 20g / L during the drying process after the last washing (pH=6.5), and then adjust its pH value with 1mol / L ammonia water. Adjust to 8 to obtain a 20g / L sepiolite dispersion; get a part of the sepiolite dispersion and dry it, and the SEM photo of the resulting powder is as follows figure 1 shown by figure 1It can be seen that the obtained sepiolite is in the form of short fibers, light and soft, and presents fiber bundles with a diameter of 50-150 nm and a length of 1-5 μm;

[0041] 2) Take by weighing 166.7g concentrated natural rubber latex (solid content 60%), then add sulfur 1g, zinc oxide 0.5g, accelerator PX0.1g, accelerator ZDC0.01g, dispersant NF0.1g...

Embodiment 2

[0056] 1) Weigh 20 grams of raw sepiolite powder (120-200 mesh) into a beaker, add 400 ml of 1 mol / L hydrochloric acid solution, stir for 15 minutes, and ultrasonically disperse at 70°C for 2 hours. After standing still for 12 hours, take the suspension, wash it repeatedly with deionized water, control the density of sepiolite to 20g / L during the drying process after the last washing (pH=6.2), and then adjust its pH value with 1mol / L ammonia water Adjust to 8 to obtain 20g / L sepiolite dispersion;

[0057] 2) Take by weighing 166.7g concentrated natural latex (solid content 60%), then add sulfur 1g, zinc oxide 0.5g, accelerator PX0.1g, accelerator ZDC0.01g, dispersant NF0.1g, 150ml step 1) to prepare The sepiolite dispersion was stirred in a water bath at 60°C for 4 hours to obtain pre-vulcanized natural rubber latex; after that, it was filtered with an 80-mesh filter, and after standing for defoaming, it was salivated into a film according to the conventional process, dried at...

Embodiment 3

[0060] 1) Weigh 20 grams of raw sepiolite powder (20-80 mesh) into a beaker, add 300 ml of 1.5 mol / L sulfuric acid solution, stir for 5 minutes, and ultrasonically disperse at 60°C for 2.5 hours. After standing still for 12 hours, take the suspension, wash it repeatedly with deionized water, control the density of sepiolite to 20g / L during the drying process after the last washing (pH=6.0), and then adjust its pH value with 1mol / L ammonia water Adjust to 8.5 to obtain a sepiolite dispersion with a density of 20g / L;

[0061] 2) Take by weighing 166.7g concentrated natural latex (solid content 60%), then add sulfur 1g, zinc oxide 0.5g, accelerator PX0.1g, accelerator ZDC0.1g, dispersant MF0.1g, potassium hydroxide 0.2g, 100ml of the sepiolite dispersion obtained in step 1), heated in a water bath at 60°C, and stirred for 4 hours to obtain pre-vulcanized natural rubber latex, filtered with an 80-mesh filter, left to defoam, and salivated into a film according to a conventional pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com