Preparation method of polyurethane modified acrylate polymeric dispersant for coatings

A technology of polymer dispersant and polyurethane modification, which is applied in coating and other directions, can solve the problems of poor versatility, limited molecular weight and molecular structure, and achieve wide compatibility, simple preparation process and easy-to-obtain products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the polyurethane-modified acrylate polymer dispersant for the coating of the present application comprises the following steps:

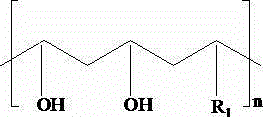

[0035] 1) Preparation of polyhydroxy acrylate

[0036] Add the solvent accounting for 50-150% of the total mass fraction into a four-necked flask equipped with a stirring and condensing device, at a temperature of 80°C to 160°C, a pressure of 0.01MPa to 1Mpa, and under the protection of nitrogen, the molar ratio of the dropwise addition is 1 : (0.01-0.1) mixture of hydroxyl-terminated acrylic monomers, acrylic monomers containing polar groups, and initiators accounting for 0.5-5% of the total mass of the reactants, dropwise for 2-5 hours, and keep warm for 1-5 hours. Cooling and filtering, spare;

[0037] 2) Polymer polyurethane synthesized from monoisocyanate

[0038] Weigh a certain mass of isocyanate multimer, monohydroxy polyether with a molar ratio of (2-6):1 to the isocyanate multimer, and a molar ratio to th...

Embodiment 1

[0053] Add 10g of monoisocyanate polyurethane C, 0.3428g of polyhydroxy acrylate A, 0.01g of dibutyltin dilaurate, and 2.586g of butyl acetate into a four-necked flask equipped with a stirring and condensing device, at a temperature of 90-100°C and Under the protection of nitrogen, stir for 3-5h, cool down and filter, the product has a solid content of 40%, and NCO%≤0.05%.

Embodiment 2

[0055] Add 10g of monoisocyanate polyurethane C, 0.4796g of polyhydroxy acrylate B, 0.01g of dibutyltin dilaurate, and 2.620g of butyl acetate into a four-necked flask equipped with a stirring and condensing device, at a temperature of 90-100°C and Under the protection of nitrogen, stir for 3-5h, cool down and filter, the product has a solid content of 40%, and NCO%≤0.05%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com