Environment-friendly snow melting agent prepared from alkaline residues and preparation method therefor

A snow-melting agent and environmental protection technology, applied in the field of environmental-friendly snow-melting agent and its preparation, can solve the problems such as the difficulty of using alkali slag, and achieve the effects of less secondary pollution, lower production costs, and better snow melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

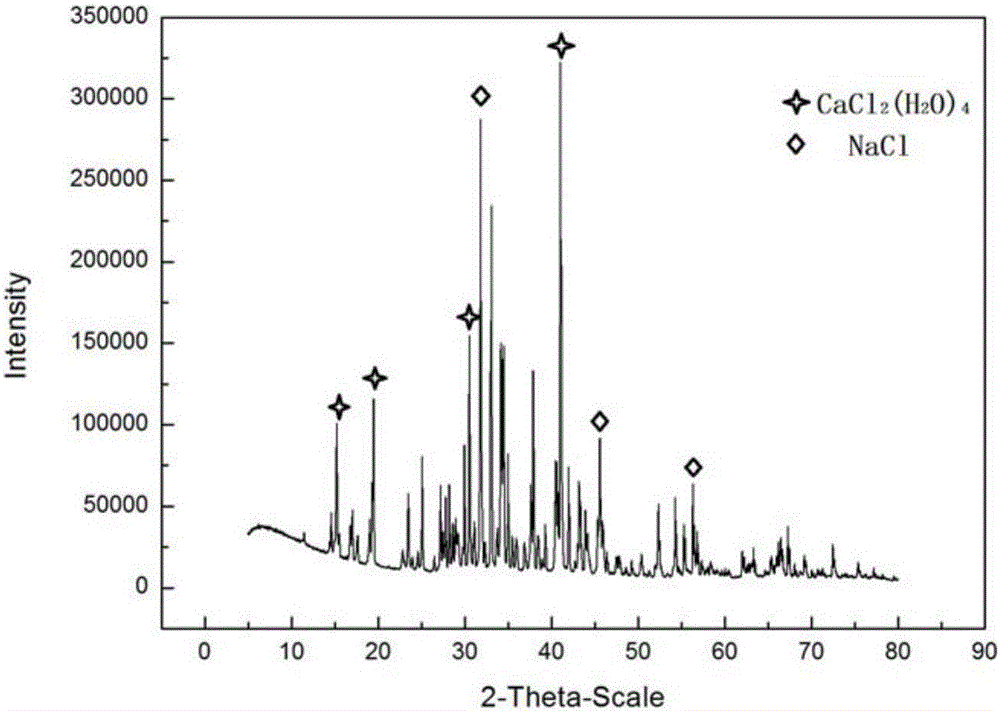

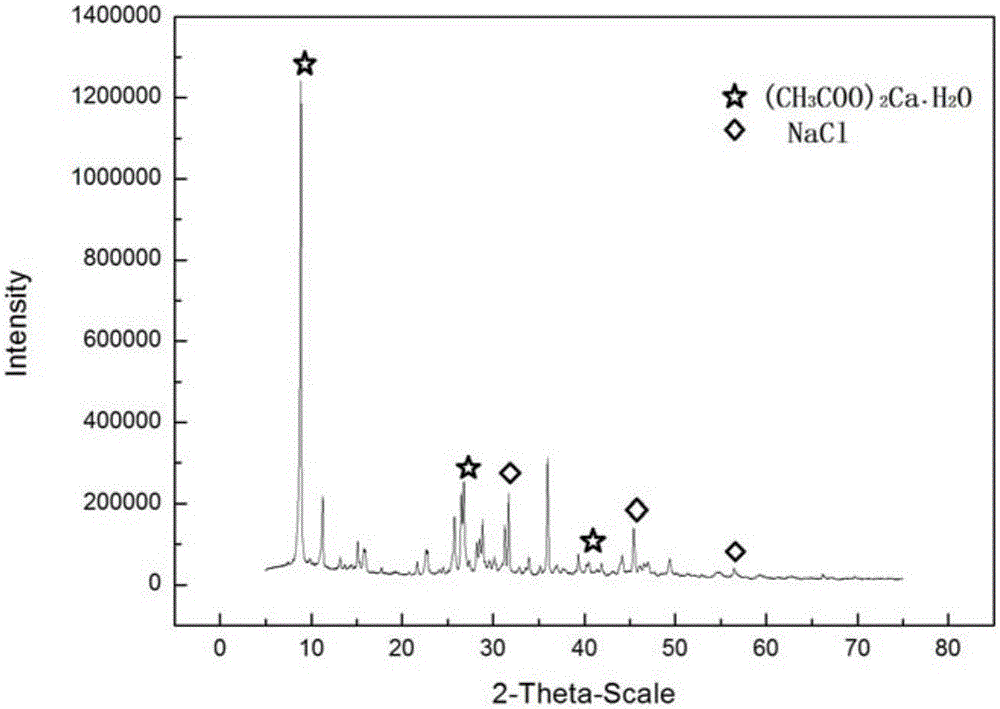

[0039] This embodiment provides an environmentally friendly deicing agent prepared from alkali slag, including a solid product reacted with alkali slag and hydrochloric acid as raw materials.

[0040] This embodiment also provides a preparation method for the solid product, including slowly adding concentrated hydrochloric acid into a reaction tank with alkali slag under stirring conditions, and reacting after 5-6 hours, detecting the pH; The slag and concentrated hydrochloric acid adjust the pH in the reaction tank to 7-8, stop the reaction, and obtain a suspension reaction solution, then carry out vacuum filtration at a vacuum degree of 20kPa, evaporate and dry to obtain a solid product. The solid product can be directly used as an environment-friendly deicing agent.

[0041] During the reaction, carbon dioxide, a by-product of the reaction, is recovered.

[0042] Its reaction formula is:

[0043] CaCO 3 +2HCl=CaCl 2 +H 2 O+CO 2 ↑

[0044] Ca(OH) 2 +2HCl=CaCl 2 +2H ...

Embodiment 2

[0049] This example provides an environmentally friendly deicing agent prepared by using alkali slag, including 75g of solid product prepared according to the method in Example 1, 15g of urea, and 10g of sodium nitrite. It can be prepared by mixing the above components evenly.

Embodiment 3

[0051] This example provides an environmentally friendly deicing agent prepared by using alkali slag, including 85g of solid product prepared according to the method in Example 1, 10g of urea, and 5g of sodium nitrite. It can be prepared by mixing the above components evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com