Anti-oxidation material and method for preparing tantalum-tungsten alloy anti-oxidation coating by using it

An anti-oxidation coating, tantalum-tungsten alloy technology, applied in the direction of metal material coating process, coating, etc., to achieve the effect of strong anti-oxidation ability under continuous static load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

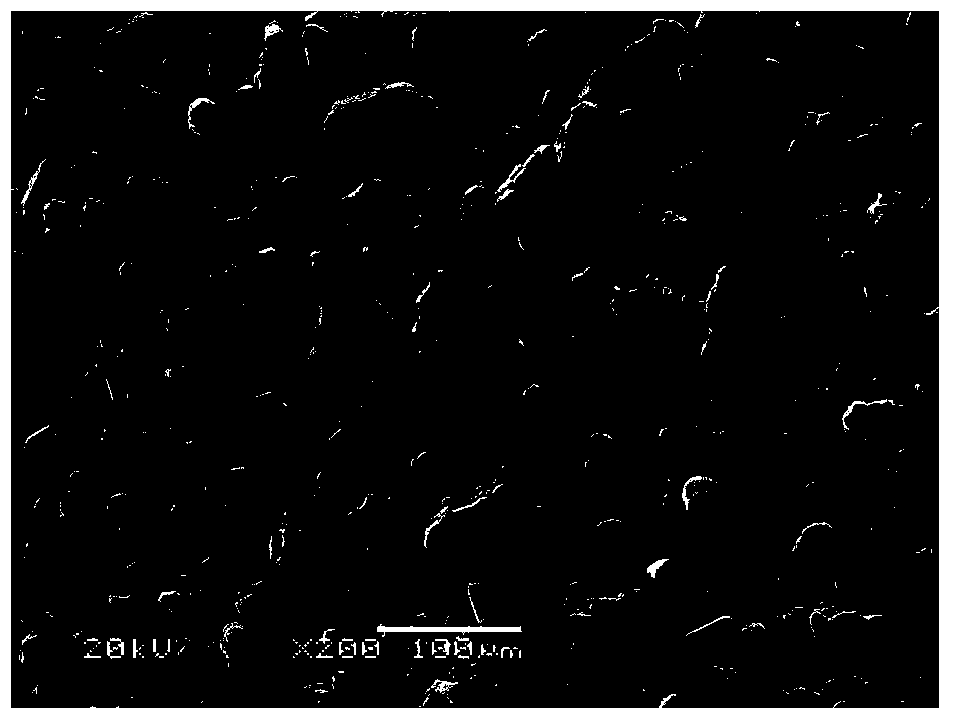

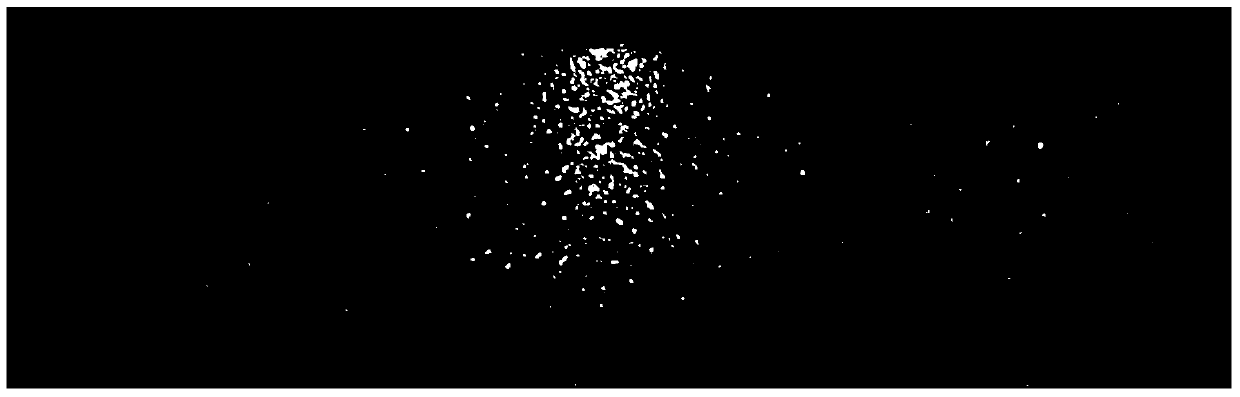

Image

Examples

Embodiment 1

[0052] 1) Two groups of high-temperature anti-oxidation materials are:

[0053] ①Cr is 5Wt%, Fe is 3Wt%, Ti is 2Wt%, Y 2 o 3 2Wt%, W is 1Wt%, HfO 2 5Wt%, Nb is 3Wt%, SiC is 2.8Wt%, B is 1.2Wt, and the balance is Si;

[0054] ②Mo is 7.2Wt%, W is 2.2Wt%, Nb is 3Wt%, Y is 2Wt%, HfO 2 4wt%, B 2 o 3 is 1.2wt%, BaO is 0.8wt%, Ta is 0.6wt%, and the balance is Si.

[0055] Mix the above two groups of materials evenly in proportion, use a planetary ball mill to grind them into powders of no more than 300 mesh at high speed, and put them into two different containers;

[0056] 2) In the ① group antioxidant material (powder), add respectively the nitro varnish (Hangzhou Paint Co., Ltd., Pagoda brand nitro varnish) of powder quality 80Wt% and the NaF of 3Wt% as binding agent and catalyst, then add powder Ethyl acetate with twice the volume was used as a carrier, mixed evenly, ball milled with corundum beads at a speed of 150r / min for 8h, and then made into a slurry. Coat the slurr...

Embodiment 2

[0068] 1) Two groups of high-temperature anti-oxidation materials are:

[0069] ①Cr is 3Wt%, Ti is 5Wt%, Y 2 o 3 2Wt%, W is 1.5Wt%, Nb is 3Wt%, HfO 2 3wt%, MoSi 2 is 2.5Wt%, S is 1Wt%, and the balance is Si;

[0070] ② Mo is 6.2Wt%, W is 3Wt%, Nb is 3Wt%, Y is 1.8Wt%, HfO 2 4wt%, Al 2 o 3 3.5wt%, B 2 o 3 is 1.2wt%, BaO is 0.8wt%, Ta is 2.2wt%, and the balance is Si.

[0071] Mix the above two groups of materials evenly in proportion, use a planetary ball mill to grind them into powders of no more than 300 mesh at high speed, and put them into different containers;

[0072] 2) Add 120Wt% nitro varnish (Zhejiang Paint Co., Ltd., Pagoda brand nitro varnish) and 3Wt% NH varnish respectively to the ① group antioxidant material 4 Cl was used as a binder and a catalyst, and ethyl acetate twice the volume of the powder was added as a carrier. After mixing evenly, ball milling with corundum beads at a speed of 150r / min for 8 hours was used to make a slurry. Coat the slurry e...

Embodiment 3

[0076] 1) Two groups of high-temperature anti-oxidation materials are:

[0077] ①Cr is 5Wt%, Ti is 2Wt%, Y 2 o 3 2Wt%, W is 0.5Wt%, Nb is 1.8Wt%, HfO 2 3.5wt%, TiB 2 is 0.25Wt%, Ir is 0.5%, and the balance is Si;

[0078] ②Mo is 7.2Wt%, W is 2Wt%, Nb is 2.2Wt%, Y is 1.5Wt%, HfO 2 4Wt%, La 1.2Wt%, B 2 o 3 is 3.7wt%, BaO is 0.8wt%, V is 0.8wt%, and the balance is Si.

[0079] Mix the above two groups of materials evenly in proportion, use a planetary ball mill to grind them into powders of no more than 300 mesh at high speed, and put them into different containers;

[0080] 2) Add polyethylene glycol (Tianjin Kemiou Co., Ltd., analytically pure grade, polyethylene glycol 3000-8000) with a powder mass of 3Wt% to the anti-oxidation material in group ① as a binder, and add 1.2Wt % NH 4 Cl and 1.8wt% NaF were used as catalysts, and ethyl acetate twice the volume of the powder was added as a carrier. After mixing evenly, ball milling with corundum beads at a speed of 180r / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com