Compound brown rice nutrition food and production method thereof

A nutritional food and brown rice technology, which is applied in food preparation, food ingredients, food heat treatment, etc., can solve the problems of affecting the taste, limiting the dissolution of nutritional and health functional substances, and the difficulty of fully exerting the nutritional and health effects, so as to improve the taste and taste. and nutritional and health benefits, and the effect of enhancing nutritional and health benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

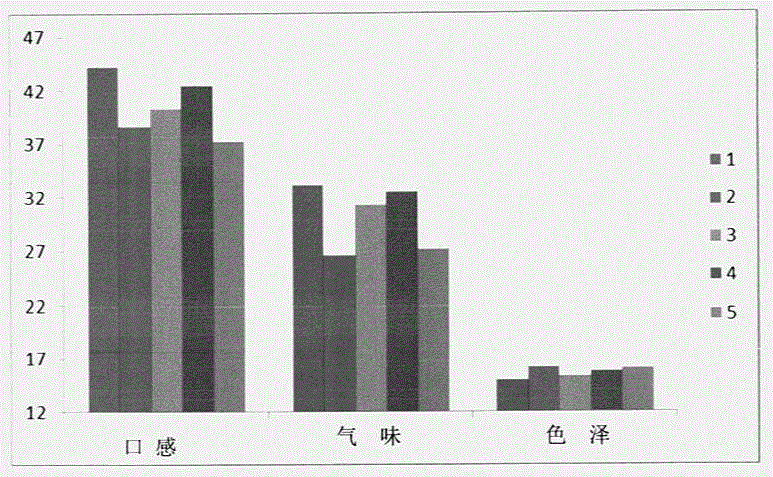

Embodiment example 1

[0027] 1. Pretreatment: Select fresh, plump brown rice, oat grains and black beans that meet the quality standard requirements, sift out impurities such as weeds and stones, and remove broken and unfulfilled raw material particles. Rinse twice with tap water 3 times the weight of raw oatmeal, drain and set aside.

[0028] 2. Raw material compounding: Weigh 10kg, 3.5kg and 1.5kg of cleaned brown rice, oat and black soybean raw materials respectively, and mix the three raw materials evenly;

[0029] 3. Conditioning: Add 3.5kg of clean water to the mixed raw materials, stir evenly, and perform conditioning. The tempering time is 10 hours, and the tempering temperature is controlled within 27±3°C.

[0030] 4. Hot-pressed steam explosion treatment: Put the mixed raw materials after conditioning in the closed explosion cylinder of the hot-pressed steam explosion device for steam explosion treatment. The steam explosion pressure is 2.0MPa, and the saturated steam temperature is 180±...

Embodiment example 2

[0050] 1. Pretreatment: Select fresh, plump brown rice, oat grains and black beans that meet the quality standard requirements, remove weeds, stones and other impurities, and remove broken and unfulfilled raw material particles. Rinse 3 times the weight of raw oatmeal with tap water twice, drain and set aside.

[0051] 2. Raw material compounding: Weigh 15kg, 4.5kg and 3.0kg of cleaned brown rice, oat and black soybean raw materials, and mix the three raw materials evenly;

[0052] 3. Conditioning: Add 5.0kg of clean water to the mixed raw materials, stir evenly, and perform conditioning. The conditioning time is 10 hours, and the conditioning temperature is controlled within 27±3°C.

[0053] 4. Hot-pressed steam explosion treatment: Put the mixed raw materials after conditioning in the closed explosion cylinder of the hot-pressed steam explosion device for steam explosion treatment. The steam explosion pressure is 1.5MPa, and the saturated steam temperature is 190±10°C. The...

Embodiment example 3

[0059] 1. Pretreatment: Select fresh, plump brown rice, oat grains and black beans that meet the quality standard requirements, sift out impurities such as weeds and stones, and remove broken and unfulfilled raw material particles. Rinse twice with tap water 3 times the weight of raw oatmeal, drain and set aside.

[0060] 2. Raw material compounding: Weigh 20kg, 4.5kg and 4.0kg of cleaned brown rice, oat and black soybean raw materials respectively, and mix the three raw materials evenly;

[0061] 3. Conditioning: Add 5.5kg of clean water to the mixed raw materials, stir evenly, and perform conditioning. The tempering time is 10 hours, and the tempering temperature is controlled within 25±3°C.

[0062] 4. Hot-pressed steam explosion treatment: place the mixed raw materials after conditioning in the closed explosion cylinder of the hot-pressed steam explosion device for steam explosion treatment. The steam explosion pressure is 1.7MPa, and the saturated steam temperature is 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com