Gas-solid separation ceramic film and preparation method thereof

A gas-solid separation, ceramic membrane technology, applied in separation methods, ceramic products, semi-permeable membrane separation, etc., can solve problems such as high toughness, membrane fracture, etc., to achieve extended service life, low cost, and reduced operation and maintenance costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

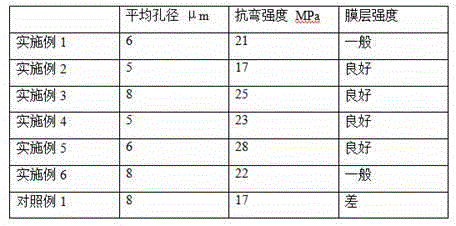

Examples

preparation example Construction

[0048] Preparation of qi solid separation film

[0049] The gas solid separation membrane of this implementation method can be manufactured through the following process: the surface coating of the porous support body of the porous support body that constitutes the separation film; and through the thermal treatment of the particles of the membrane liquid sintering, the surface of the support body forms the membrane layer on the surface of the support bodyWork.

[0050] Among them, the preparation of porous support can be mixed with silicon carbide powder with a small amount of pores (such as charcoal powder, graphite, starch, and wood chips).Ligue agent.The percentage content of the final silicon carbide or toughened auxiliary in the support body is calculated with the amount of these raw materials at the time of adding, and the pores will disappear during the sintering process. Therefore, when calculating the weight of the particle weightNot counting inside.If you use a static p...

Embodiment 1

[0065] Preparation of silicon carbide gas solid -separated ceramic film, the raw material slurry composition of the support body is as follows: 80G supporting raw material raw materials of carbide silicon powder is 100 μm, toughest auxiliary is oxide particles, the particle size is 5 μm, 10g;10g of graphite, sintering auxiliary MGO3G.After waiting for the static pressure molding process, the body is obtained, and the support body is obtained after 4 hours of sintering by 1400 ° C.

[0066] The raw material of the membrane is 80g of alumina powder, the particle size is 20 μm, and the rest are polyethylene alcohol 5g, polyethylene pyrirol 2g, and 160g of de -ion water.membrane.After getting a wet film, after 5 hours of drying and sintering at 1200 ° C, the qi solid separation film is obtained.

Embodiment 2

[0068] Preparation of silicon carbide gas solid -separated ceramic film, the raw material slurry composition of the support body is as follows: 85G supporting raw material raw material carbonic silicon powder particle size of 200 μm, the toughened auxiliary agent is aluminum fiber, the average particle size is 3 μm, 5g;10g of pores starch, sintering auxiliary MGO5G.After waiting for the static pressure molding process, the body is obtained, and the support body is obtained after 4 hours of sintering by 1500 ° C.

[0069] The ingredients of the membrane liquid are 80g of alumina powder, the particle size is 15 μm, the toughened auxiliary is 15g of oxide particles, the particle size is 20nm, the rest are 2g of polyvinyl alcohol, the polyethylene pyrigone 4g, and 140g of exfoliating water.The ball mill is prepared to obtain the membrane liquid, and then the membrane is covered by the grining method.After getting a wet film, after 4 hours of drying and sintering at 1100 ° C, the qi so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com