Novel magnetic active carbon and preparation method thereof

A magnetic activated carbon, a new type of technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems of complex preparation conditions and difficulty in mass production, and reduce processing costs. Good reuse effect, enhanced application feasibility and market competitiveness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

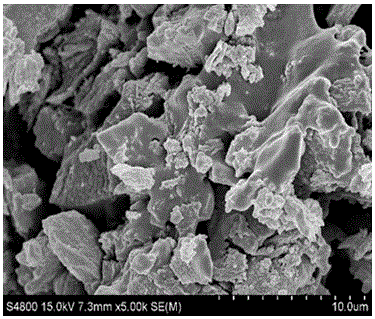

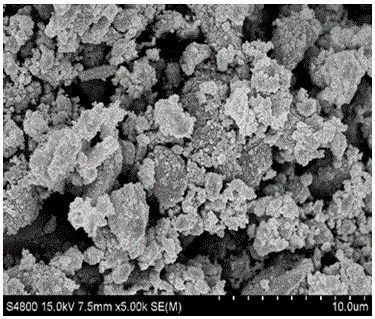

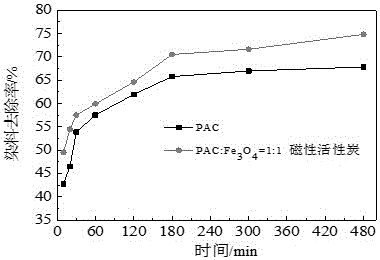

[0024] Example 1: A new type of magnetic activated carbon, powdered activated carbon: PAC and nano-iron oxide: Fe 3 o 4 of composite materials. PAC / Fe 3 o 4 The mass ratio is 1.

[0025] A preparation method of a new type of magnetic activated carbon, using chemical co-precipitation method, in Fe 3+ / Fe 2+ (Molar ratio)=2 In the reaction system, powdered activated carbon is used as a carrier to complete the reaction by adding lye medium;

[0026] The Fe 3+ / Fe 2+ (molar ratio)=2 reaction system is FeCl3 / FeSO4 (molar ratio)=2 or FeCl3 / FeCl2 (molar ratio)=2;

[0027] The lye medium is NaOH;

[0028] Powdered activated carbon is PAC.

[0029] The specific steps of the chemical co-precipitation method are: 1. PAC is dried in an oven for 24 hours at a temperature of 100 ° C; The solution is mixed at a temperature of 50°C, and a certain amount of PAC is added to the mixed solution to control the PAC / Fe in the composite material. 3 o 4 ratio, and continued to stir, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com