Noble metal nano ring and preparation method thereof

A technology of nano-rings and noble metals, applied in the field of noble metal nano-rings and its preparation, can solve the problems of low product purity and uncontrollable Pt high-selectivity growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

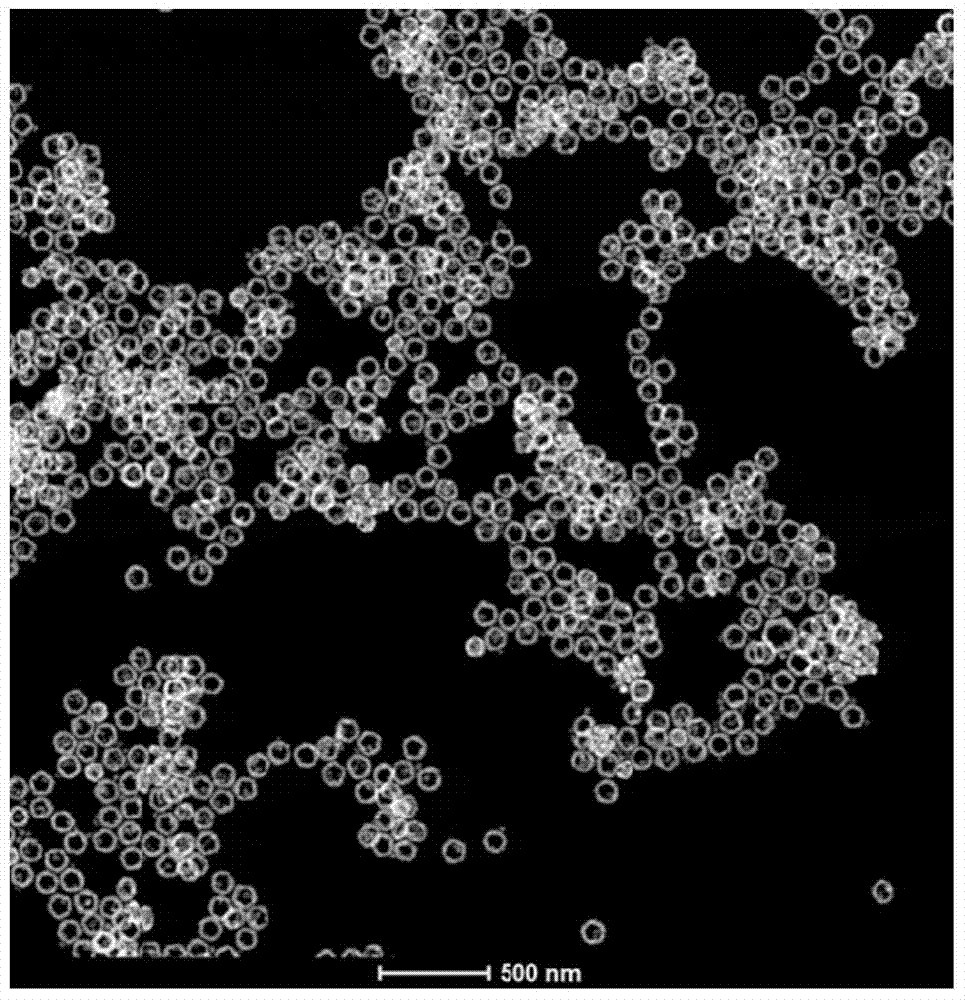

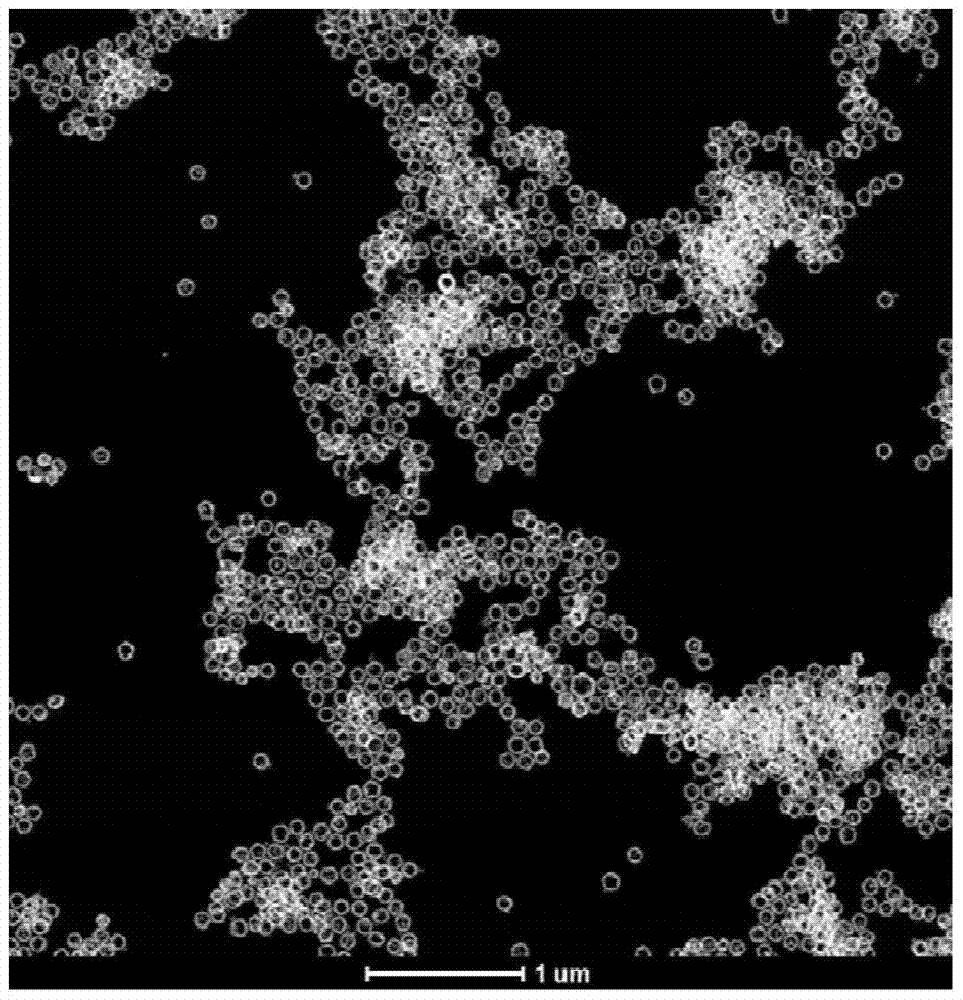

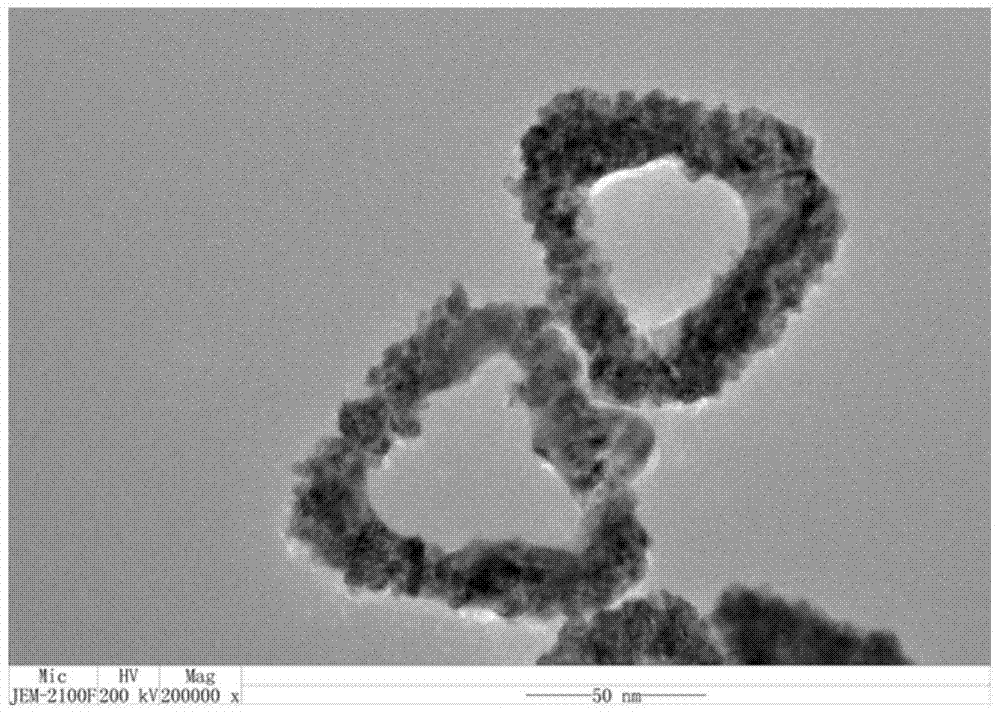

[0031] Another aspect of the present invention relates to a method for preparing the aforementioned noble metal nanorings, which includes:

[0032] Step A, prepare Au nano material template solution: add HAuCl to the protective agent-reducing agent I mixture in sequence 4 And AgNO 3 After uniform mixing, an Au nanomaterial mixing reaction system is obtained, and the Au nanomaterial mixing reaction system is reacted to prepare an Au nanomaterial template liquid;

[0033] Step B, preparing precious metal nanorings: adding M source and reducing agent II to the Au material template solution and mixing uniformly, and then reacting to prepare precious metal nanorings.

[0034] In a specific embodiment of the present invention, in step A, the Au nanomaterial mixing reaction system is reacted (under aerobic conditions) to prepare an Au nanomaterial template solution. The Au nanomaterial template liquid contains decahedral Au nanoparticle seeds protected by a protective agent, and AgCl is als...

Embodiment 1

[0086] Example 1: Preparation of Au nanomaterial template liquid containing Au decahedral nanoparticles

[0087] Mix 20mL of polyol with 0.4mL of polydiallyldimethylammonium chloride with a certain concentration and molecular weight and stir evenly, then add 5mg of dried HAuCl 4 , Then add 10mg AgNO 3 . After the mixed solution is evenly stirred, the solution is reacted in an oil bath for 30 minutes, and the size of the decahedron can be adjusted by controlling the reaction temperature.

[0088] The polyhydric alcohol is ethylene glycol, glycerol, pentanediol and the like.

[0089] The molecular weight of the polydiallyldimethylammonium chloride is 200,000-1,000,000.

[0090] The mass concentration of the polydiallyldimethylammonium chloride is 20% to 35%.

[0091] The reaction is carried out in an oil bath, and the chloroauric acid must be dried before use. The temperature of the oil bath is 180-220℃.

[0092] The concentration of chloroauric acid is 2-8 mg / mL.

Embodiment 2

[0093] Example 2: Preparation of Au nanomaterial template liquid containing Au nanosheets

[0094] Mix 20mL of polyol with 0.4mL of polydiallyldimethylammonium chloride with a certain concentration and molecular weight and stir evenly, then add 5mg of dried HAuCl 4 , Then add 10mg AgNO 3 . After the mixed solution is uniformly stirred, nitrogen gas is blown for 30 minutes to remove oxygen in the solution, and then nitrogen gas is continued to react in an oil bath for 30 minutes. The Au nanosheet size can be adjusted by controlling the reaction temperature.

[0095] The polyhydric alcohol is ethylene glycol, glycerol, pentanediol and the like.

[0096] The molecular weight of the polydiallyldimethylammonium chloride is 200,000-1,000,000.

[0097] The mass concentration of the polydiallyldimethylammonium chloride is 20% to 35%.

[0098] The reaction is carried out in an oil bath, and the chloroauric acid must be dried before use.

[0099] The oil bath temperature is 180-220°C.

[0100] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com