Preparation method of metallic arsenic single crystal

A metal arsenic, single crystal technology, applied in the fields of metallurgical technology and material science and engineering, can solve the problems of complex surface structure and crystal structure, high oxidation risk, low economic value, etc. Mirror glossy effect on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

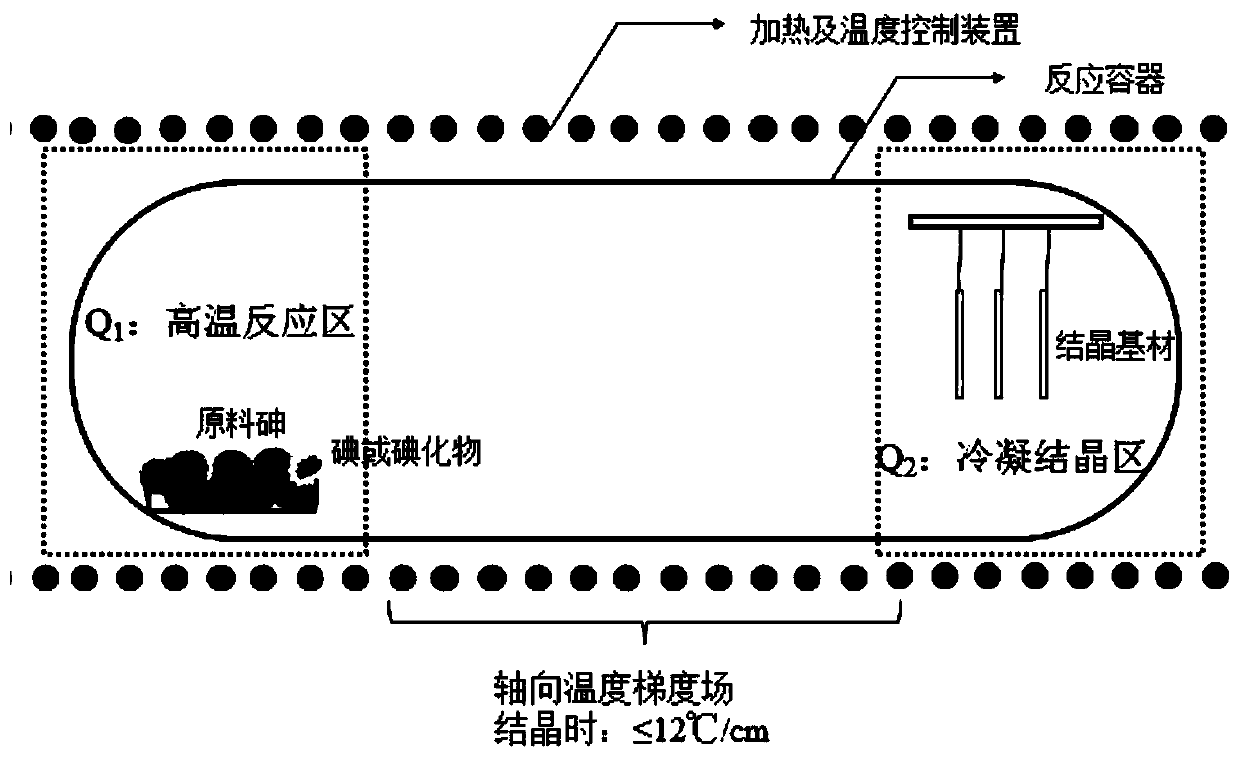

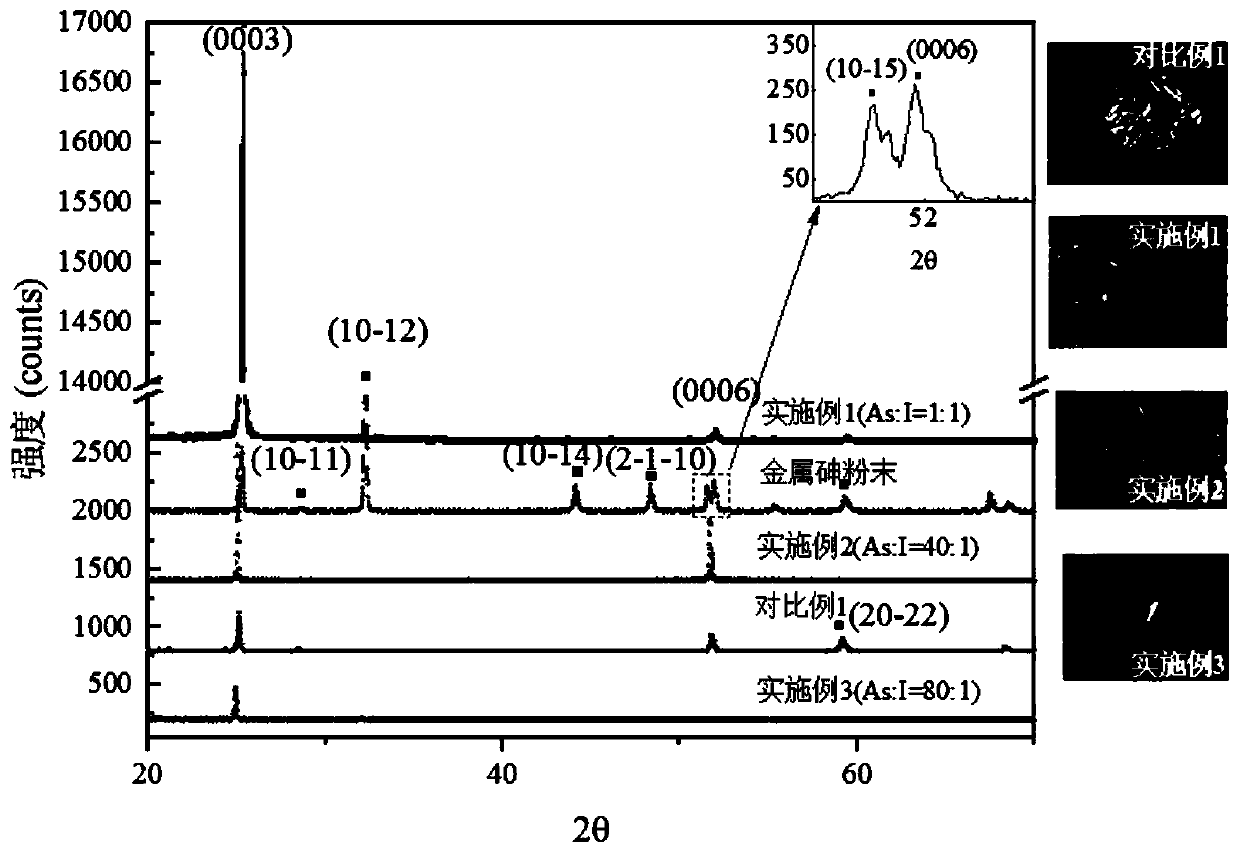

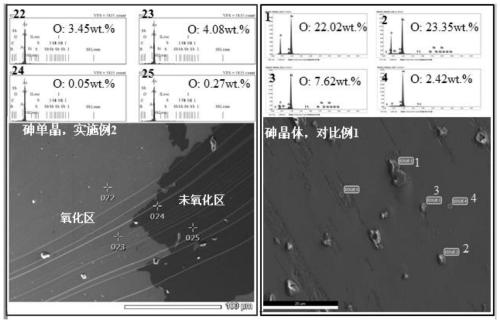

[0025] The mass of metal arsenic raw material is 1.9g, and the maximum reaction pressure is about 1.2MPa in a closed container. According to the molar ratio of As and I is 1:1, mix elemental arsenic and elemental iodine and place them in the Q1 area, and react at 650°C for 30min. At the same time, the arsenic vapor generated by the reaction condenses and crystallizes at 500 ° C in the Q2 area, and the axial temperature gradient between the Q1 area and the Q2 area is 8 ° C / cm, and the metallic arsenic single crystal is obtained;

[0026] After condensing and crystallizing the metal arsenic single crystal, the temperature in the Q2 area is lowered to 150°C, and the temperature in the Q1 area is lowered to 48°C to condense and recover elemental iodine and continue to use it for the reaction.

Embodiment 2

[0028] The mass of metal arsenic raw material is 2.2g, and the maximum reaction pressure is about 1.5MPa in a closed environment. According to the molar ratio of As and I is 40:1, the elemental arsenic and arsenic triiodide are mixed and placed in the Q1 area, and reacted at 700°C For 40 minutes, the arsenic vapor generated by the reaction was condensed and crystallized at 520 °C in the Q2 area, and the axial temperature gradient between the Q1 area and the Q2 area was 9 °C / cm, and the metallic arsenic single crystal was obtained;

[0029] After the metal arsenic single crystal is obtained by condensation and crystallization, the temperature in the Q2 area is lowered to 150°C, and the temperature in the Q1 area is lowered to 48°C to carry out condensation recovery of arsenic triiodide and continue to use it for the reaction.

Embodiment 3

[0031] The mass of metal arsenic raw material is 1.1g, and the maximum reaction pressure is about 0.7MPa in a closed environment. According to the molar ratio of As and I is 80:1, the elemental arsenic and elemental iodine are mixed and placed in the Q1 area, and reacted at 650°C for 60min. At the same time, the arsenic vapor generated by the reaction condenses and crystallizes at 500 °C in the Q2 area, and the axial temperature gradient between the Q1 area and the Q2 area is 8 °C / cm, and the metallic arsenic single crystal is obtained;

[0032] After condensing and crystallizing the metal arsenic single crystal, the temperature in the Q2 area is lowered to 150°C, and the temperature in the Q1 area is lowered to 48°C to condense and recover elemental iodine and continue to use it for the reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com