Welding gun spray pipe and machining method thereof

A processing method and nozzle technology, used in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of easy slag hanging and easy burnout, and achieve the effects of not easy to deform, prolong service life, and good electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

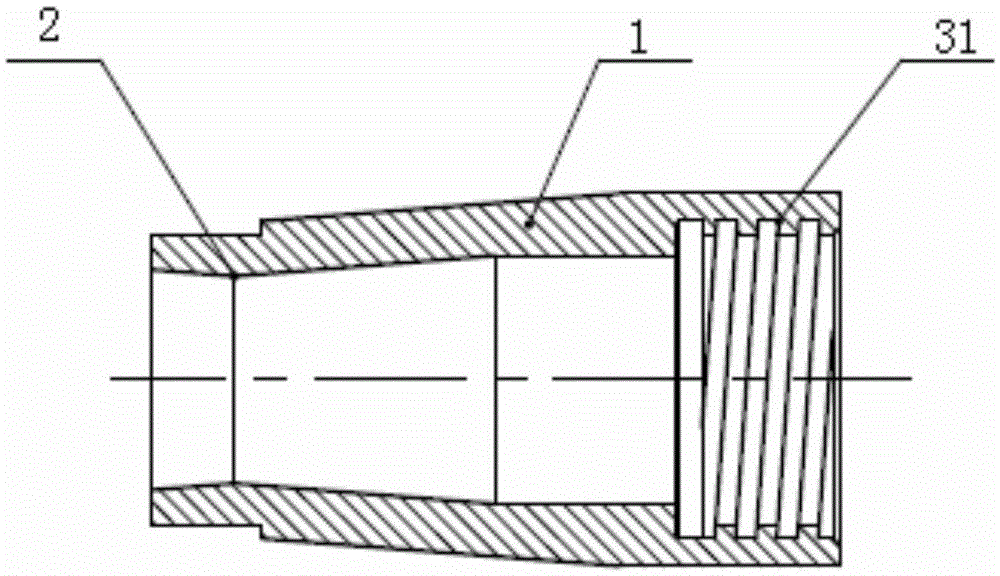

[0035] See figure 1 , the nozzle of the present embodiment is an integrated nozzle, comprising a connected nozzle main body 1 and a nozzle 2 located at the head of the nozzle main body 1; the nozzle main body 1 and the nozzle 2 are both hollow structures; the nozzle main body 1 The tail of the nozzle is provided with a connection structure 3; the main body of the nozzle 1 and the nozzle 2 are reinforced graphite; the reinforced graphite is mainly composed of graphite, and 2 to 3% of glass fiber and 3 to 5% of boric acid or 2 to 5% of boric acid are added to the graphite. 5% silicon carbide. The connection structure 3 may be an internal thread or an external thread, and in this embodiment it is an internal thread 31 for connecting with other parts of the welding torch.

[0036] The processing technology is:

[0037] Step 1: preparing reinforced graphite rods; the reinforced graphite rods use graphite as the main body, and add 2-3% glass fibers and 3-5% boric acid or 2-5% sili...

Embodiment 2

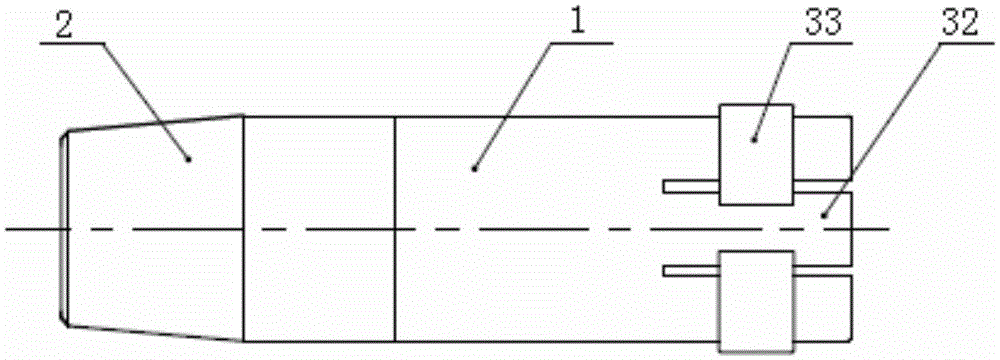

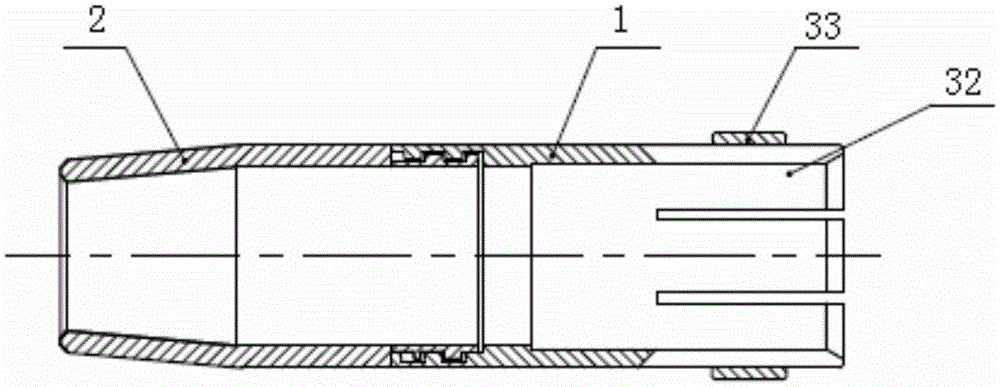

[0047] See figure 2 and image 3 , The nozzle of this embodiment is a split nozzle, the nozzle body 1 and the nozzle 2 are connected by threads, and the nozzle body 1 is made of red copper. The connection structure 3 is an elastic connection structure. The connection structure 3 includes a plurality of warping pieces 32 and an annular elastic piece 33; the multi-piece warping pieces 32 are axially arranged at the tail of the nozzle main body 1 with a gap between them. The annular elastic piece 33 is sheathed on the outside of the plurality of warping pieces 32 . Since the graphite material has no elasticity, it cannot adapt to the elastic assembly with parts. This structure can not only ensure the heat resistance and strength of the nozzle head, but also ensure the elastic assembly required for the assembly of the nozzle tail with other parts.

[0048] The process of processing the nozzle is consistent with that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com