Method and device for forming a moldless material

A material molding and molding method technology, applied in ceramic molding machines, ceramic molding workshops, manufacturing tools, etc., can solve the problems of uneven mixing and poor controllability of moldless molding, and achieve easy control of curing, high density, and improved The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] (1) Preparation of monomer premix: adding organic monomers and water-soluble polymers into deionized water to form a solution, the mass ratio of which is: organic monomers: water-soluble polymers: water=15~40:0.3~5 :100;

[0028](2) Preparation of the first and second slurries: the first slurries contain catalysts, and their specific components include: solvents, dispersants, powder materials, polymerizable monomers, crosslinking agents, viscosity regulators, water-soluble Polymers, pH regulators, defoamers and catalysts can be formulated according to the general ratio. This method can be applicable to adding catalyst and self-catalyzed material, wherein the preferably adding volume of the catalyst solvent of adding catalyst is 0.1~6vol% of the volume of the first slurry, within this range by adjusting the addition amount of initiator and catalyst and its Ratio, controllable induction period is 5s ~ 5min, suitable for moldless molding process; the second slurry contain...

Embodiment 1

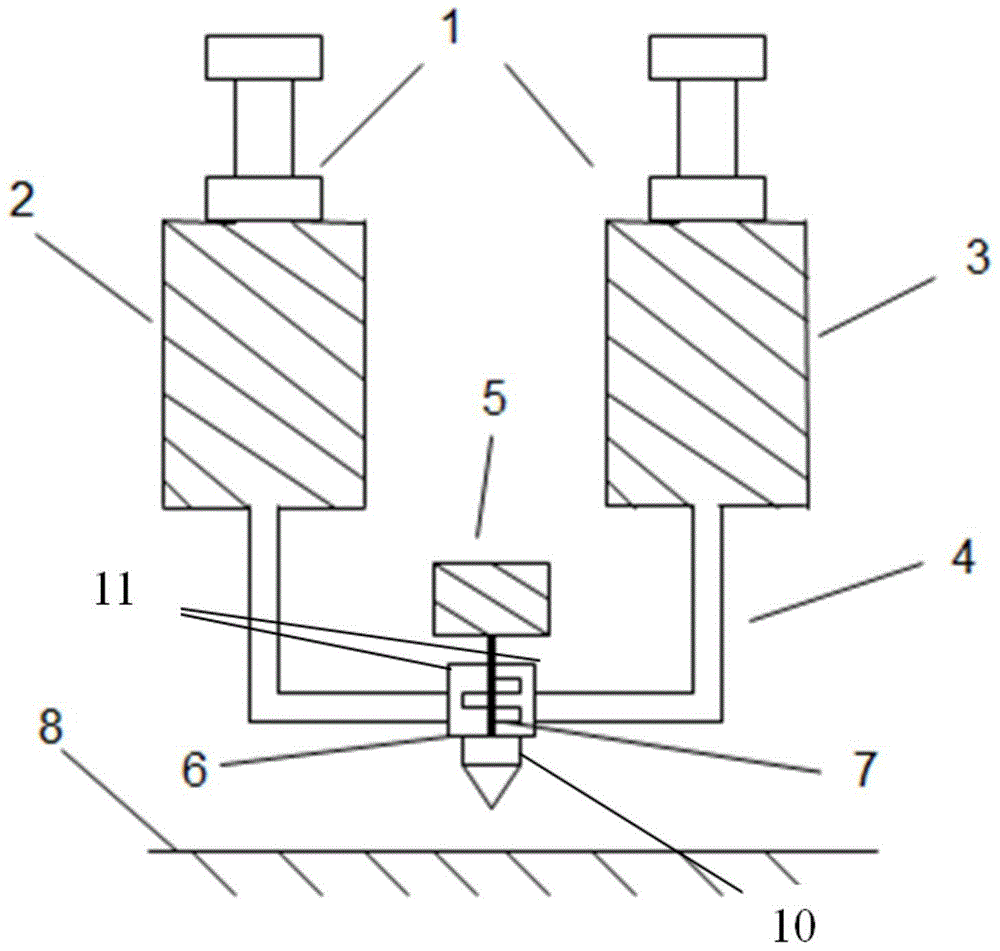

[0042] A material forming device such as figure 1 As shown, it includes first and second storage containers, a premixing device and a 3D printing device, the first and second storage containers are connected to the premixing device, and the premixing device is connected to the nozzle of the 3D printing device; The premixing device includes two feeding ports 11 , a mixing chamber 6 , stirring blades 7 and a motor 5 . The first and second storage containers 2 and 3 are connected to a premixing device, and the premixing device is connected to a nozzle 10 of a 3D printing device; the premixing device includes a mixing chamber 6 with two feeding ports 11 , stirring blade 7 and motor 5, the feed inlet is connected with the first and second storage containers 2 and 3 respectively, the stirring blade 7 is placed in the mixing chamber 6, the stirring blade 7 is connected with the motor 5, Stirring is carried out in the mixing chamber 6 driven by the motor 5 . Wherein the nozzle 10 is...

Embodiment 2

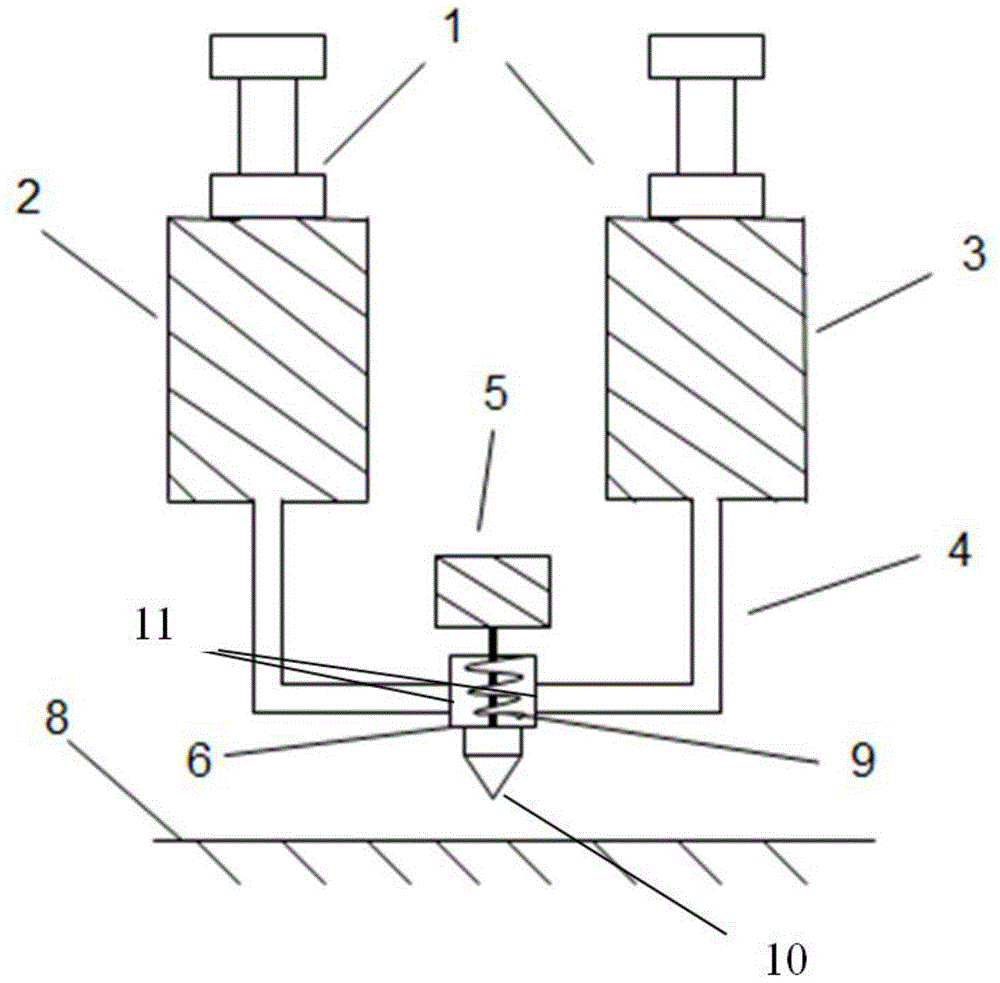

[0044] A material forming device such as figure 2 As shown, it includes first and second storage containers, a premixing device and a 3D printing device, the first and second storage containers are connected to the premixing device, and the premixing device is connected to the nozzle of the 3D printing device; The premixing device includes two feeding ports 11 , a mixing chamber 6 , stirring blades 7 and a motor 5 . The first and second storage containers 2 and 3 are connected to a premixing device, and the premixing device is connected to a nozzle 10 of a 3D printing device; the premixing device includes a mixing chamber 6 with two feeding ports 11 , stirring blade 7 and motor 5, the feed inlet is connected with the first and second storage containers 2 and 3 respectively, the stirring blade 7 is placed in the mixing chamber 6, the stirring blade 7 is connected with the motor 5, Stirring is carried out in the mixing chamber 6 driven by the motor 5 . Wherein the nozzle 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com