Ce<1-x>Zr<x>O2 buffer layer and preparation method thereof

The technology of buffer layer and precursor liquid is applied in the field of high-temperature superconducting material preparation, and achieves the effects of low cost of raw materials, simple preparation process and wide source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

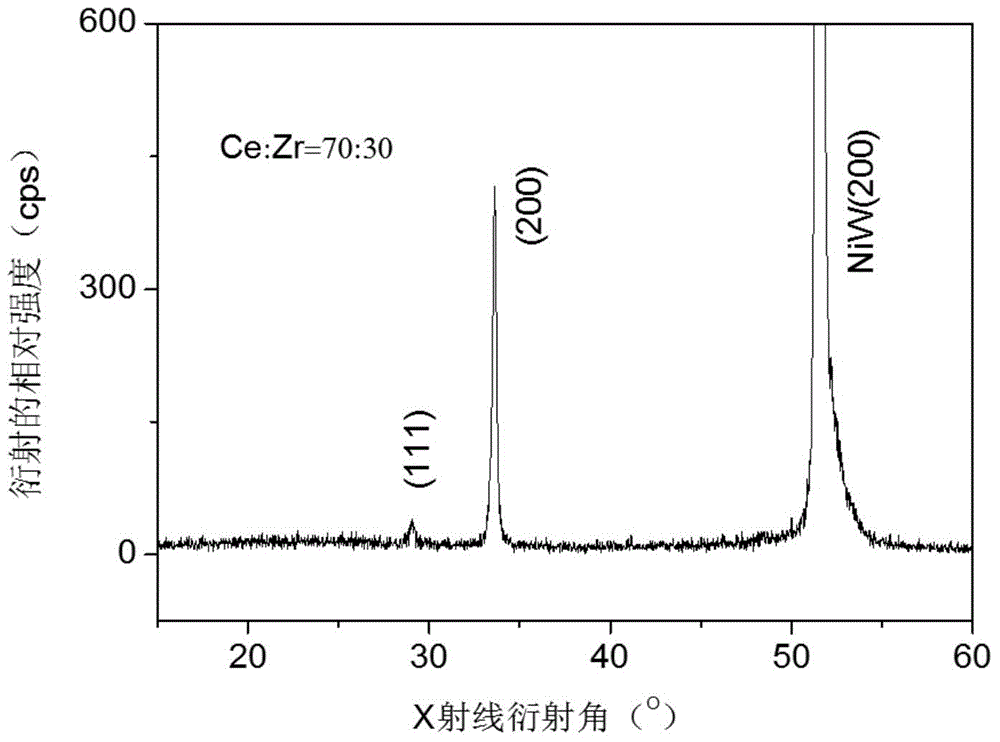

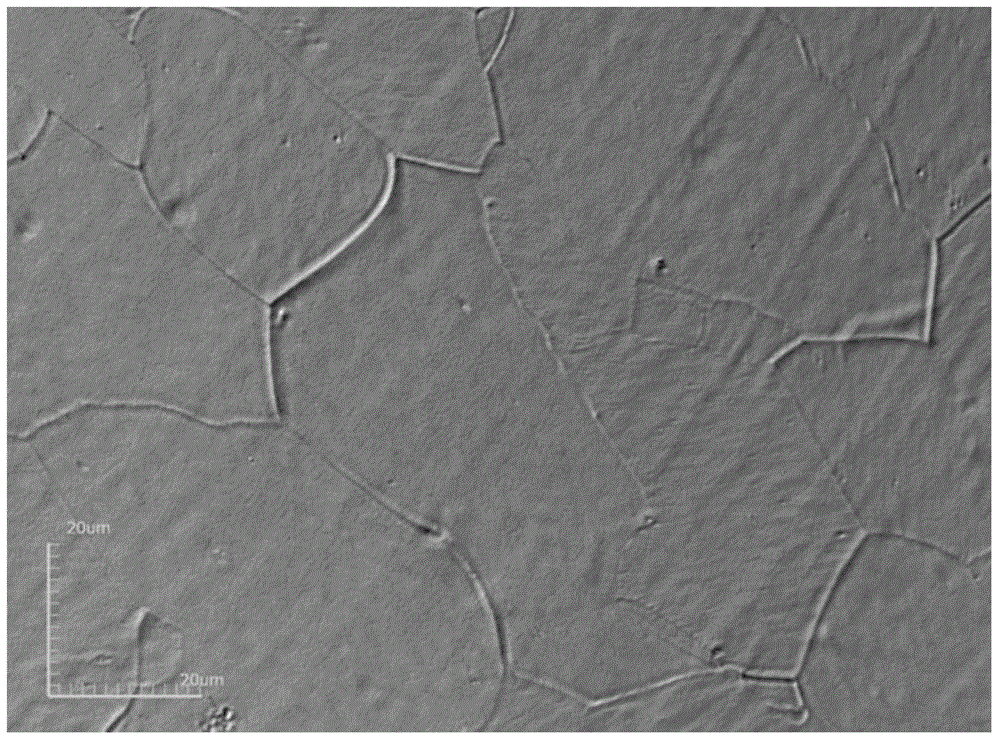

[0034] Ce 0.7 Zr 0.3 o 2 Preparation of the buffer layer:

[0035] Get x to be 0.3, cerium nitrate hexahydrate and zirconium oxychloride octahydrate are dissolved in the solvent according to the mol ratio of Ce: Zr=0.7:0.3, and solvent is anhydrous methanol; Calculate according to the total moles of metal ions, adjust The amount of solvent added to obtain a precursor solution with a metal ion concentration of 0.1mol / L; the prepared precursor solution was coated on a NiW metal substrate by dip coating, and then the NiW metal substrate coated with the precursor solution was coated on a muffle The furnace was pretreated at 150 °C for 10 min; the treated precursor solution was put into a quartz tube sintering furnace for heat treatment, and under the protection of a reducing atmosphere, the temperature in the furnace was raised to 300 °C at a heating rate of 3 °C / min. Insulation for 8 minutes, wherein the reducing atmosphere is 96% Ar and 4% H by volume fraction 2The mixed gas...

Embodiment 2

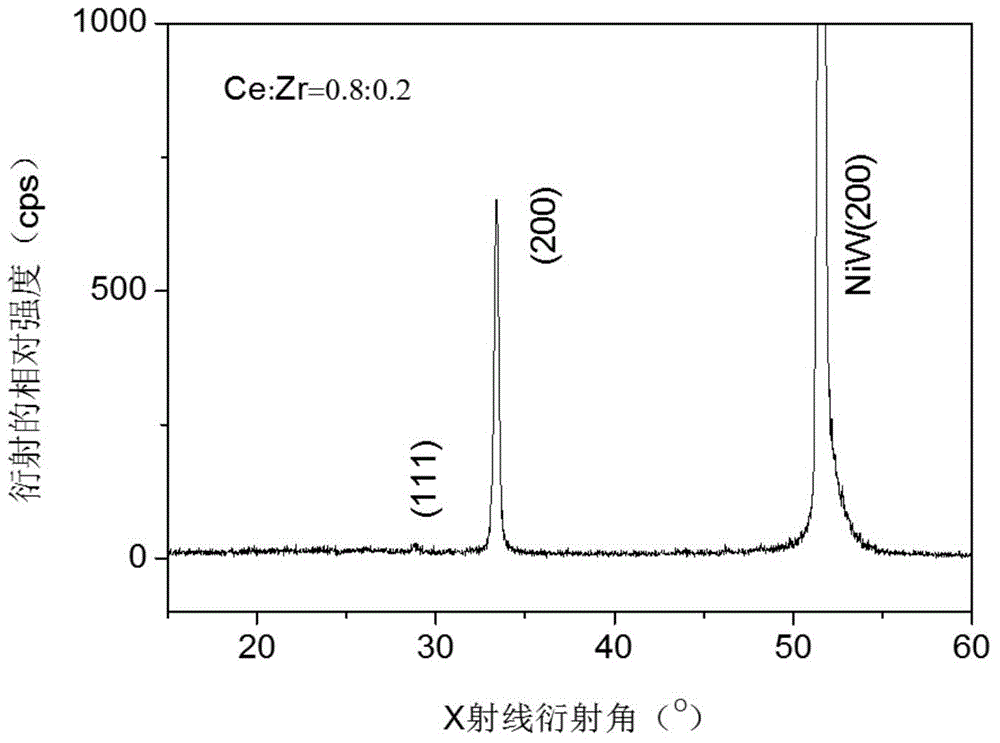

[0039] Ce 0.8 Zr 0.2 o 2 Preparation of the buffer layer:

[0040] Get x to be 0.2, cerium nitrate hexahydrate and zirconium oxychloride octahydrate are dissolved in the solvent according to the mol ratio of Ce: Zr=0.8:0.2, and solvent is the mixed solution of ethylene glycol methyl ether and methyl alcohol; Calculate the total number of moles, adjust the amount of solvent added, and obtain a precursor solution with a metal ion concentration of 0.3mol / L; use the dip coating method to coat the prepared precursor solution on the NiW metal substrate, and then apply the precursor solution coated with The NiW metal substrate was pretreated in a muffle furnace at 180°C for 13 minutes; the treated precursor liquid was put into a quartz tube sintering furnace for heat treatment, and the temperature in the furnace was increased at a heating rate of 5°C / min under the protection of a reducing atmosphere. Raise to 300°C and hold for 9 minutes, wherein the reducing atmosphere is 96% Ar ...

Embodiment 3

[0044] Ce 0.9 Zr 0.1 o 2 Preparation of the buffer layer:

[0045] Get x to be 0.1, cerium nitrate hexahydrate and zirconium oxychloride octahydrate are dissolved in the solvent according to the mol ratio of Ce: Zr=0.9: 0.1, and solvent is in the mixed solvent of methyl alcohol, ethylene glycol methyl ether and acetylacetone, Wherein methyl alcohol: ethylene glycol methyl ether: the mass ratio of acetylacetone is 9:4:1; Calculate according to the total moles of metal ions, adjust the add-on of solvent, obtain the precursor solution that metal ion concentration is 0.4mol / L; Adopt The prepared precursor solution is coated on the NiW metal substrate by the dip coating method, and then the NiW metal substrate coated with the precursor solution is pretreated in a muffle furnace at 200°C for 15 minutes; the processed precursor solution is put into a quartz tube Carry out heat treatment in a sintering furnace. Under the protection of a reducing atmosphere, the temperature in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com