A kind of preparation method of perovskite structure ceramic coating

A technology of perovskite structure and ceramic coating, which is applied in coating, metal material coating process, fusion spraying, etc., can solve the problem that thermal barrier coating cannot be used in high-temperature and high-speed gas scour environment, poor process controllability, Combined with the problems of low strength, it achieves the effects of excellent oxygen barrier performance, high erosion resistance and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A method for preparing a perovskite-like structure ceramic coating, the specific steps of the method are as follows:

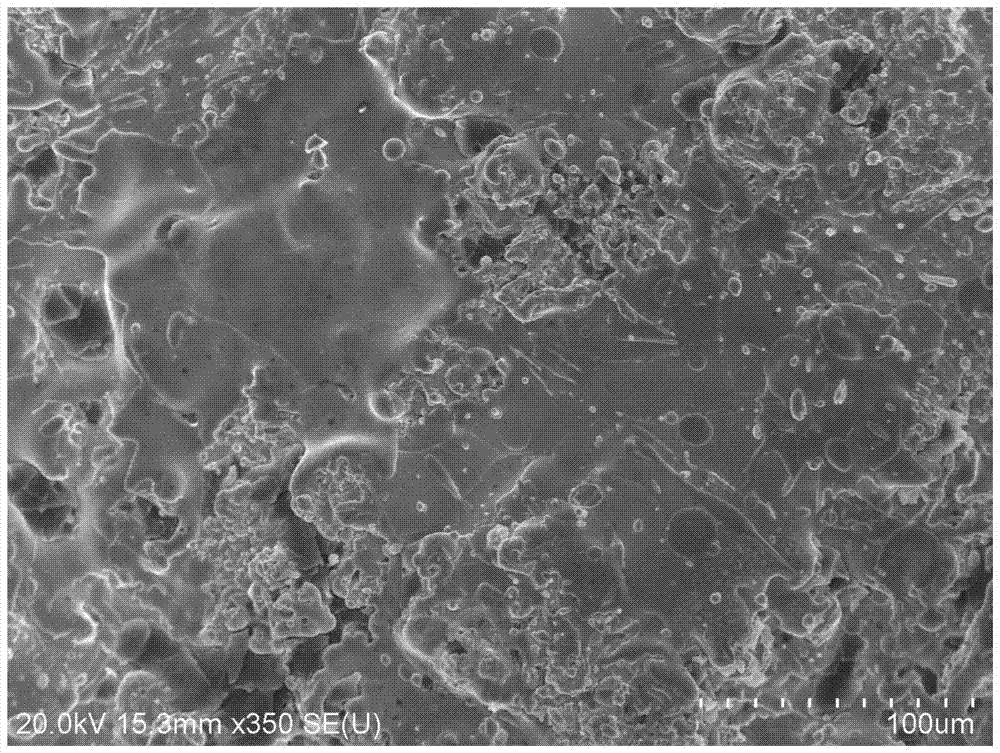

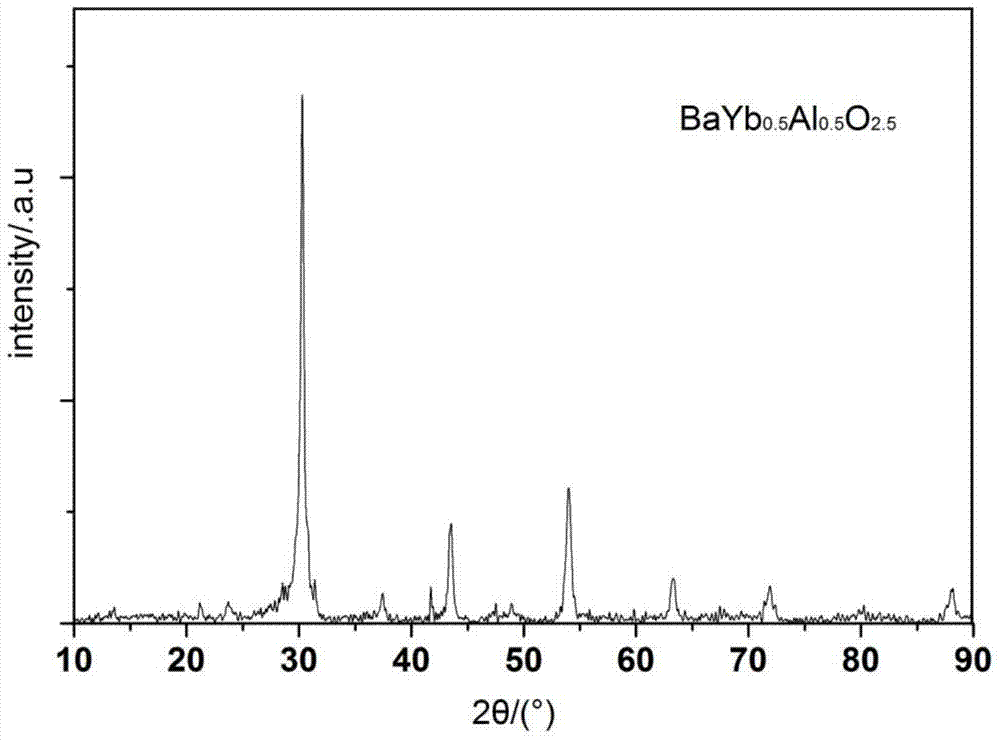

[0051] (1) Add 61.4g BaCO to the ball mill jar of planetary ball mill 3 , 7.94g Al 2 o 3 , 30.66g Yb 2 o 3 and 300g of absolute ethanol, with alumina ball milling beads as the ball milling medium, the ball to mass ratio is 4:1, the rotation speed of the ball mill is set to 400r / min, and the ball mill is 6h to obtain the mixed slurry a; after the mixed slurry a is vacuum-dried , using a 300-mesh standard inspection sieve to obtain a mixed powder with a particle size of less than 50 μm;

[0052] (2) Put the mixed powder in a crucible for a muffle furnace, set the temperature rise rate of the muffle furnace to 3°C / min, raise the temperature to 1000°C, keep it for 10h, then raise the temperature to 1500°C, keep it for 4h, and cool with the furnace to 18°C to obtain powder a;

[0053] (3) Add powder a, absolute ethanol and polyvinylpyrrolidone into t...

Embodiment 2

[0063] A method for preparing a perovskite-like structure ceramic coating, the specific steps of the method are as follows:

[0064] (1) Add 62.43g BaCO to the ball mill jar of planetary ball mill 3 , 8.07g Al 2 o 3 , 29.5g Yb 2 o 3 and 300g of absolute ethanol, with alumina ball milling beads as the ball milling medium, the ball to mass ratio is 4:1, the rotation speed of the ball mill is set to 400r / min, and the ball mill is 6h to obtain the mixed slurry a; after the mixed slurry a is vacuum-dried , using a 300-mesh standard inspection sieve to obtain a mixed powder with a particle size of less than 50 μm;

[0065] (2) Place the mixed powder in a crucible for a muffle furnace, set the temperature rise rate of the muffle furnace to 6°C / min, raise the temperature to 1200°C, keep it for 8 hours, then raise the temperature to 1600°C, keep it for 3 hours, and cool with the furnace to 25°C to obtain powder a;

[0066] (3) Add powder a, absolute ethanol and polyvinylpyrrolido...

Embodiment 3

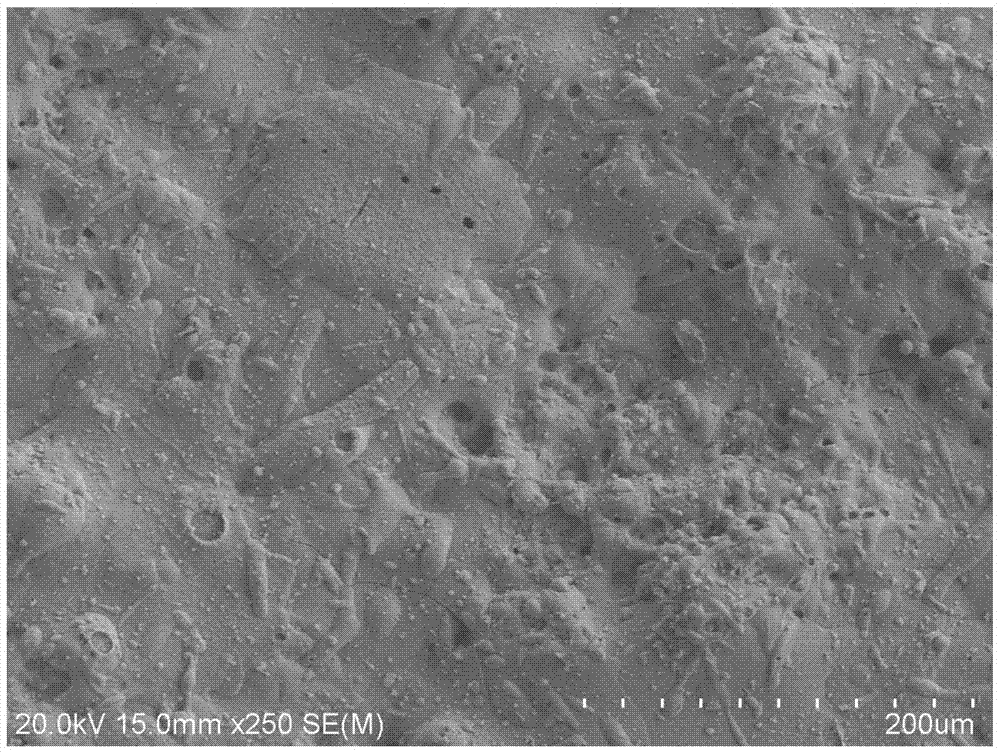

[0076] A method for preparing a perovskite-like structure ceramic coating, the specific steps of the method are as follows:

[0077] (1) Add 62.43g BaCO to the ball mill jar of planetary ball mill 3 , 8.07g Al 2 o 3 、29.50Dy 2 o 3 and 300g of absolute ethanol, with alumina ball milling beads as the ball milling medium, the ball to mass ratio is 4:1, the rotation speed of the ball mill is set to 400r / min, and the ball mill is 6h to obtain the mixed slurry a; after the mixed slurry a is vacuum-dried , using a 300-mesh standard inspection sieve to obtain a mixed powder with a particle size of less than 50 μm;

[0078] (2) Put the mixed powder in a crucible for a muffle furnace, set the temperature rise rate of the muffle furnace to 5°C / min, raise the temperature to 1300°C, keep it for 6h, then raise the temperature to 1560°C, keep it for 2.5h, Cool to 30°C to obtain powder a;

[0079] (3) Add powder a, absolute ethanol and polyvinylpyrrolidone into the ball milling tank, us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com